Scenario-based solutions for implementing an internet of things system at the organizational level in small- and medium-sized enterprises

Abstract

BACKGROUND:

Despite the great potential that technical solutions, based on the Internet of Things (IoT), offer for companies, especially small and medium-sized enterprises (SMEs), companies are hesitant to implement such solutions. Reasons for this lie in the resulting far-reaching change, which particularly affects working activities and communication between employees and IoT objects in their environment.

OBJECTIVE:

Our objective is to investigate (1) how the implementation of an IoT solution, consisting of multiple objects, might be integrated into daily working activities; (2) what reactions might occur at the individual level; and (3) what structural conditions should be established at the organizational level.

METHODS:

We applied a scenario-based design. Specifically, we conducted interviews to develop personas and scenarios describing human–machine interactions during implementation of the IoT solution in an initial phase.

RESULTS:

Regarding changing work activities, we identified three structural conditions that facilitate the implementation of IoT in SMEs: (1) the development of a support unit that bundles communication and training activities as well as internal and external knowledge; (2) the planning of an appropriate testing and adoption phase that enables participation and feedback; and (3) the creation of an incentive structure that includes social reward, empowerment, and recognition.

CONCLUSION:

IoT gives employees enhanced access to resources, information, and feedback, supporting an efficient way of working. To successfully implement IoT solutions, companies, especially SMEs, must actively address organizational change and empower their employees to manage technological innovations at an early stage.

1Introduction

The increasing implementation of the Internet of Things (IoT) offers great potential, especially for small and medium-sized enterprises (SMEs). IoT fundamentally describes a network of physical and virtual objects that communicate with each other or with other devices connected to the internet [1, 2]. The smart network of objects associated with the IoT [3] enables access to real-time information for goods and processes [4, 5], thus realizing cost reduction potentials [6] and optimizing customer satisfaction [7]. This advantage is particularly applicable to SMEs, as they profit from increased flexibility [8].

However, the attributes of the IoT also lead to fundamental changes within organizations, especially in the execution of processes and in employees’ communications with each other or with the IoT objects in their working environment. These changes arise from the increasing interaction between IoT devices and systems, generating a large amount of data, performing single tasks autonomously, and providing feedback to employees on their activities [5, 9, 10]. As a result of the consequent automation of operational activities, existing processes and tasks are subject to far-reaching changes [10]. The lack of financial and human resources in SMEs and the influence of various external environmental factors [11] thus often lead to uncertainty about the successful implementation of IoT solutions. Negative resistance or hindrance workarounds among employees [12], caused by familiarity with known systems and loss aversion [13], intensify this uncertainty. A lack of skills in handling IoT devices and big data also affects employees’ perception of stress [14] and not only negatively affects individual and organizational performance [4] but also causes psychobiological stress reactions (e.g., increased heart rate, elevated cortisol (stress hormone) levels) [15]. Further studies indicate that so-called technostress [16] may also lead to mental health diseases or mental health symptoms including burnout, depression, and cognitive difficulties [17, 18].

The previous research on the potential impact of the IoT has mainly focused on large companies in different industries [19] and application domains [20]. Studies in this context highlight cost reduction potentials, efficiency and effectiveness increases, and resulting business model innovations [21]. However, there has been little research on the impact of IoT solutions on employees’ activities, workflows, and competencies [4, 21, 22]. Moreover, studies on the potential impact of the IoT rarely focus on SMEs [23–25], and the few studies that do, do not specifically focus on organizational structures and working processes in SMEs. This is a grave oversight as such focus is highly relevant in the creation of appropriate structural conditions for employee empowerment [26] leading to increased satisfaction, performance, and competencies. While some researchers have provided relevant insights into employee empowerment through IoT at the individual level [27], it remains unclear how organizational and procedural conditions should be designed in an IoT context considering employee needs [28]. To address this research gap, we aim to investigate the following research questions. (1) How can the implementation of an IoT solution consisting of multiple objects be integrated into daily working activities? (2) What reactions might occur at the individual level? (3) What structural conditions should be established at the organizational level? In particular, we develop personas and apply a scenario-based design (i.e., problem scenarios, activity scenarios, information scenarios, and interaction scenarios) to adequately map the reactions of potential user groups and their interactions with an IoT system at the individual level. A scenario-based design is used to illustrate how a new system will affect employee activities [29] and serves as an adequate method when there is no precise concept of the instruments to be used or the order and timing in which the work steps should be executed [30]. Scenarios are particularly suitable for describing human–machine interactions [31] involving future systems at an early stage. In summary, a scenario-based design enables a realistic, detailed, and accurate description of current problems as well as future requirements and potential uses [29]. As we investigate how the implementation of IoT affects activities and working practices and subsequently derive requirements for structural conditions, a scenario-based design appears appropriate for answering our research questions.

In doing so, we contribute to SME research and practice by providing guidance on the aspects that SMEs should consider at the organizational level when implementing IoT-based solutions.

2Theoretical foundation

In the following, we first elaborate key characteristics of IoT and the implementation of IoT solutions at the organizational level. Moreover, we elucidate resulting challenges at the individual level. Alongside, we highlight the differences between IoT and ICT.

2.1IoT solutions in organizations

Basically, the IoT describes the global cross-linking of intelligent objects that are connected to each other via the internet. Intelligent objects include the smallest independent sensors, complex devices, and system environments. Linking these objects with the internet enables them to communicate with each other and generate data [32]. Despite different views of IoT (i.e., thing-oriented, internet-oriented, semantics-oriented) in relation to ubiquitous intelligence, smart connectivity, and support [33], the commonalities in understanding can be applied to the following definition: “A conceptual framework that leverages on the availability of heterogeneous devices and interconnection solutions, as well as augmented physical objects providing a shared information base on global scale, to support the design of applications involving at the same virtual level both people and representations of objects.” [32]. In addition, multilayer approaches specify the components of the IoT and interactions between single IoT objects, thus contributing to an increased understanding of IoT architecture. For instance, a five-layer architecture comprises a perception layer, transport layer, processing layer, application layer, and business layer [34]. Summarizing the findings, the IoT is primarily characterized by (1) a certain number of physical objects in the (working) environment, (2) the simultaneous use of applications that reveal a variety of received data to users, and (3) an increased level of automation in terms of information exchange and processes. In contrast to conventional information systems in organizations, such as assembly [35] or production activity control systems [36], IoT systems are not solely controlled by their users but rather communicate directly with each other, enabling total automation of processes and tasks. Thus, IoT is a collective term for various novel information systems. These include cyber-physical assembly systems, digital assistance systems [37] and autonomous production control [36].

In this context, IoT solutions offer a wide range of potential applications in different industries. First, IoT supports various electronic and nonelectronic devices [38], for example, retail peripherals such as barcode scanners and payment terminals, devices in the manufacturing industry and medical devices, as well as materials, monuments and food. However, wearables (i.e., smart clothing) and tracking devices also play an increasingly important role in industry [39, 40]. Second, the Industrial Internet of Things (IIoT) offers complex solutions that significantly support various industrial sectors [41, 42]. These IoT solutions are mostly based on five key IoT technologies: radio frequency identification, wireless sensor networks, middleware, cloud computing, and IoT application software [43]. A relevant example in industry is smart factory, which increases the speed of production and profits and minimizes human interactions and, accordingly, health risks [44]. For example, IoT devices will automatically identify a machine failure and initiate a service order [42].

The implementation of IoT has a profound impact on organizations [45]. First, IoT enables the creation of optimized supply structures and collaboration with customers [46], thus changing the internal planning function. Due to IoT’s provision of real-time, in-depth information and short feedback loops, products and services can be modified accordingly. Big data and real-time visibility enable detailed planning and allow new services to be offered [47]. Second, the organizational function changes because an increased degree of self-regulation and the progressive establishment of procedural standards [48, 49] have an enormous impact on the organization of existing processes. The organizational learning and further advancement of appropriate standards can then be used to generate added value in various business units. Third, machine sensor technology performs simple manual activities and thus forms the basis for optimized control. The resulting operational efficiency, improved accuracy, and reduction in human errors offer immense benefits [50]. Fourth, a further impact of the IoT is a considerable degree of autonomy. Interconnected, intelligent devices have the capability to autonomously gather information about their environment, determine their own service needs, and recognize users’ preferences [40]. In addition, autonomous products can connect and interact with other devices or systems. By reducing the need for operators and enabling improved operation and interaction between remote locations, IoT systems also generate great potential value for companies [40]. In SMEs, the manufacturing sector is particularly affected by the implementation of IoT, with a focus on the development of technological services [51]. A key driver for the implementation of IoT systems in SMEs is the generation of process innovations with the aim of reducing costs, shortening changeover times and creating clarity in the production environment [52]. In conclusion, the implementation of IoT enables SMEs to improve their competitive position [53] and profit from their flexibility, agility and innovation capacity [54].

2.2Responses to IoT solutions and resulting challenges for implementing IoT solutions

The implementation of IoT solutions is linked to fundamental organizational and process-related changes [1]. According to social technical system theory, for the implementation of a new system to be successful, there must be an understanding that an organization is a combination of technical and social parts [55, 56]. The technical parts include the hardware and software as well as the facilities and tasks of an organization. The social parts include the people in the organization and the organizational structure, which specifically refers to employees’ cognitive abilities. Those parts interact with each other, which makes it a complex task to implement new information systems into an organization [57, 58].

Mumford [59] highlighted that the human parts of a system (employees) have the same priority as the technical parts. Thus, in this paper, we concentrate on the effects of existing IoT solutions on employees to contribute to the understanding of what must be considered when implementing an IoT solution in an organization. During the implementation of IoT solutions, concerns about disqualification, fear of job loss, and skepticism about redesigning familiar working tasks are to be expected at the individual level [60]. In the IoT context, the concept of “technostress” [48], which identifies “technostress creators” (i.e., techno-overload, techno-invasion, techno-complexity, techno-security, techno-uncertainty), can be applied. These factors lead to reduced job satisfaction and consequently lower organizational commitment. In addition, “technostress creators” have a negative impact on employees’ technology-based performance [61, 62]. However, due to limited personnel and time resources, SMEs in particular are dependent on the performance of their employees, making them a major contributor to company success [63]. Considering the aforementioned attributes of IoT, it can be summarized that, unlike user-centric ICT, IoT solutions offer a significant degree of flexibility while reducing similar structured routine activities and providing high volumes of data. This enormously amplifies mental reactions on an individual level.

Accordingly, a first challenge is to empower employees while ensuring that they maintain their individual performance. On the one hand, capacity building is a key factor for individual performance [64], including actions intended to increase employees’ knowledge and qualifications, to generate learning cycles and, thus, to contribute to organizational growth [64, 65]. In the IoT context, capacity building activities require adjustment, as general narrow traits (i.e., emotional resilience, teamwork disposition, work drive, visionary); IT-specific narrow traits (i.e., personal innovativeness in IT, computer playfulness) [66] and various IT-related skills (i.e., information gathering techniques, planning and control of systems) [67] are needed. In contrast to user-centric ICT, IoT systems affect the retention of operational knowledge about tasks performed by IoT objects as well as decision-making processes [27]. A second key factor for individual performance is employee motivation [68]. Intrinsic motivation, which is caused by the sense-giving nature of work, is a major factor in this regard [69]. Second, the enhancement of employees’ professional and personal competencies as well as the preservation of intrinsic motivation also poses challenges to the prevailing corporate culture. After all, bureaucratic regulations and protracted decision-making processes negatively counteract autonomous action and the handling of new IoT solutions [70]. Examples of potential cultural barriers include strict hierarchies and hierarchical decision-making processes, silo thinking and knowledge monopolies, strict rules, control and mistrust, fear of making mistakes, and loss of control [70]. A third potential challenge is the lack of experience in changing established processes and structures. Due to the object-centric character of IoT solutions, there is enormous potential for change, especially at the process level, through faster and more automated process navigation and tracking, direct feedback on results, and real-time communication between IoT objects [27]. Accordingly, general dysfunctionalities, such as a high degree of bureaucracy and limited communication flows, initially have an inhibiting effect [71]. In the context of the further development or renewal of existing products and services, researchers have put forward the thesis that innovation processes in numerous companies are constructed by systematically rejecting new ideas for expanding their range of products and services at an early stage [72]. This procedure occurs particularly when companies have little experience in developing and implementing technological innovations and the innovation systems are geared to the criteria of product innovations [72]. In this context, a fourth challenge in the implementation of the IoT in SMEs is the integration of external resources and broad information as well as the generation of synergies [73]. Due to the low permeability of company boundaries and a lack of networking behavior [74], new external knowledge can be integrated and used only to a limited extent. In this context, the “not-invented-here” syndrome, which describes the irrational, often unconscious, devaluation or rejection of external knowledge, is an important factor [75].

3Method

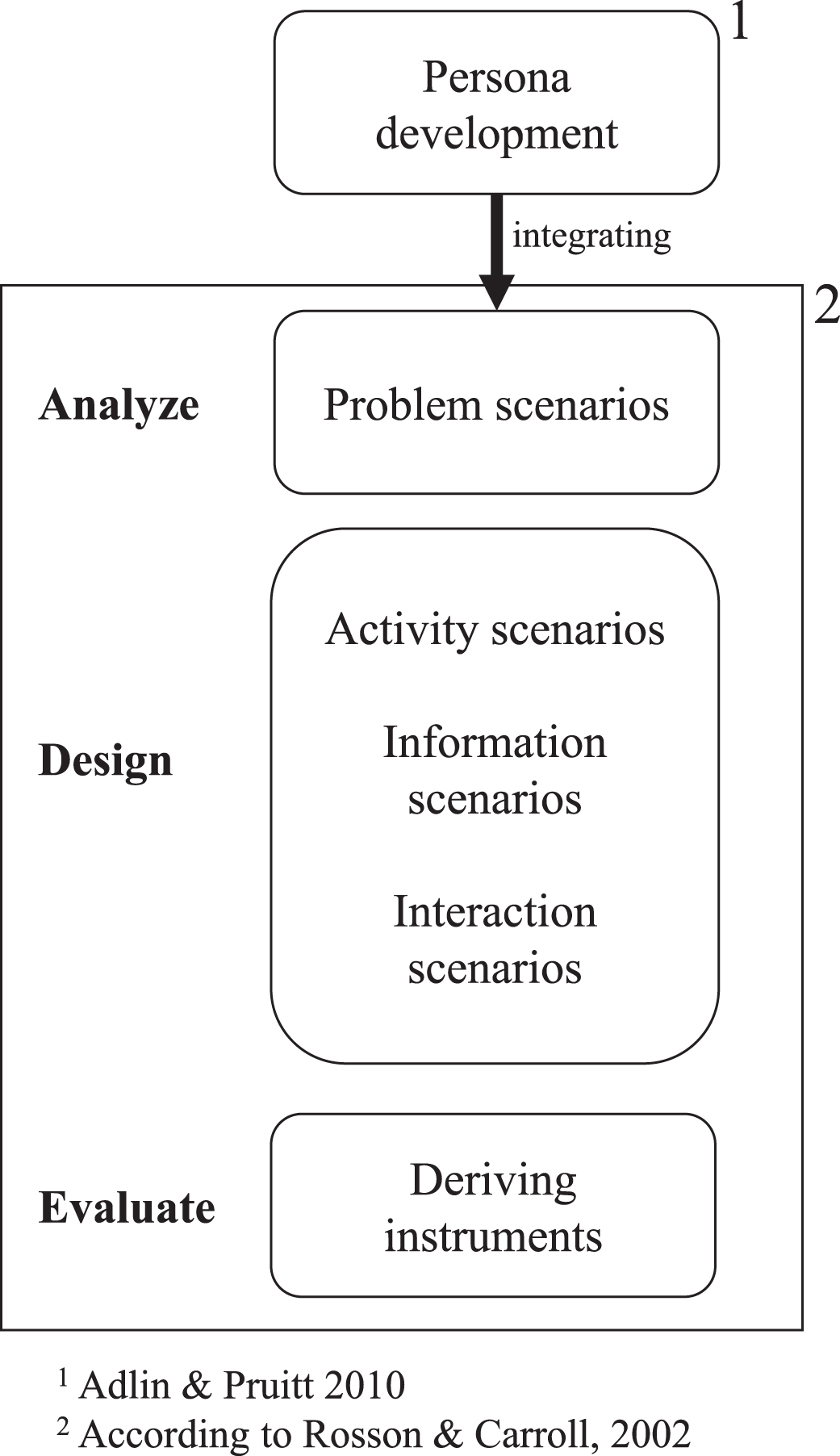

In this chapter, we apply the scenario-based development (SBD) framework according to Rosson and Carroll [29]. In subchapter 3.1, we describe the methodological development of personas, based on interviews that we conducted with managing directors. On the same data basis, we integrated the personas into their current working situation in order to determine the problem scenarios of the SBD framework. In subchapter 3.2, we relied on semi-structured interviews with different expert groups, to create activity, information and interaction scenarios. The used methodical approach can be seen in the figure below.

Fig. 1

Methodical approach used in this paper.

3.1Development of personas and their current working situation

The empirical approach of a scenario-based design allowed us to explore the planned implementation of an IoT system at an initial phase of the development process, incorporating the activities and behaviors of potential user groups [31]. In the first step, we developed so-called personas, i.e., fictitious individuals that reflected the characteristics of different user groups. Detailed elaboration of the personas provided the basis for the development of the scenarios visualizing the incorporation of new systems [76, 77]. To develop the personas on an empirical basis, we followed Adlin and Pruitt’s five-step procedure [78]. First, we conducted interviews with four managing directors and senior executives of three SMEs to create ad hoc personas. We conducted the interviews online via video telephony and structured the discussion by asking the following questions according to the guidelines of Adlin and Pruitt [78]:

• How could a fictitious employee in the internal logistics, marketing or sales/service departments in your company be characterized concerning the following factors? (1) name; (2) age; (3) education; (4) occupation; (5) place of residence; (6) interests, hobbies; (7) character traits, values, beliefs; (8) technical skills, handling of programs

• How are your employees’ work tasks structured with regard to the following factors? (9) daily routine; (10) division of labor; (11) hierarchy; (12) job formation; (13) coordination; (14) spatial workflow; (15) temporal workflow; (16) assignment of work; (17) cooperation; (18) learning

Based on questions 1–8, the respondents reported on eight typical characters as ad hoc personas that would be in contact with IoT solutions. Second, the first and second authors processed the interview data using a collaborative Excel sheet where we recorded the descriptions of all ad hoc personas and classified them into subcategories following the interview questions. Third, the subcategories were used to form skeletons containing brief descriptions for each subcategory out of the ad hoc personas. Fourth, we sought feedback from our interviewees to prioritize the skeletons in a further collaborative digital workshop. Here, we evaluated the relevance of each skeleton and aggregated the findings into three skeletons as they partly overlapped. Fifth, we transformed these final skeletons into specific personas by including individualized and personal details (e.g., family, hobbies, character traits). Finally, we reconciled the modifications with the interviewees again to verify that the developed personas adequately represented the potential user groups of IoT systems in SMEs.

Based on questions 9–18, and in line with the previous procedure, we recorded the current working situation (i.e., problem scenario), including daily routine, division of labor, processes, and cooperation with colleagues, parallel to the development of the personas. We noted the description, together with the character traits of the personas, on our collaborative Excel sheet. In the subsequent digital workshop, we obtained feedback from the participants to ensure that the current working situation was realistically formulated and that no relevant aspects were neglected in the aggregation of the personas.

3.2Development of scenarios

Following the scenario-based development (SBD) framework [29], we created scenarios that enabled a structured analysis of the prevailing working situation in the second step. The SBD framework can be used to conceptualize the basic functionality, interaction sequences and information layout of the (IoT) solution by constructing activity, interaction, and information scenarios [29]. Within the activity scenario, we focused on the basic goals and motivations of this new activity rather than the specific steps of user interaction. The activity scenario simultaneously considered and promoted new options and their realizations to reduce the previously identified area of concern [29]. Activity scenarios were followed by information scenarios, which aimed to analyze the needs of new and inexperienced users [29]. The focus of the information scenario was on the development of an exemplary IoT system and the users’ understanding, especially with regard to the needs of new and inexperienced users [29]. The interaction scenario identified possible interactions between users and the IoT system, describing individual interaction steps in detail [29]. Accordingly, the scenarios served as a grounded environment in which the personas could operate.

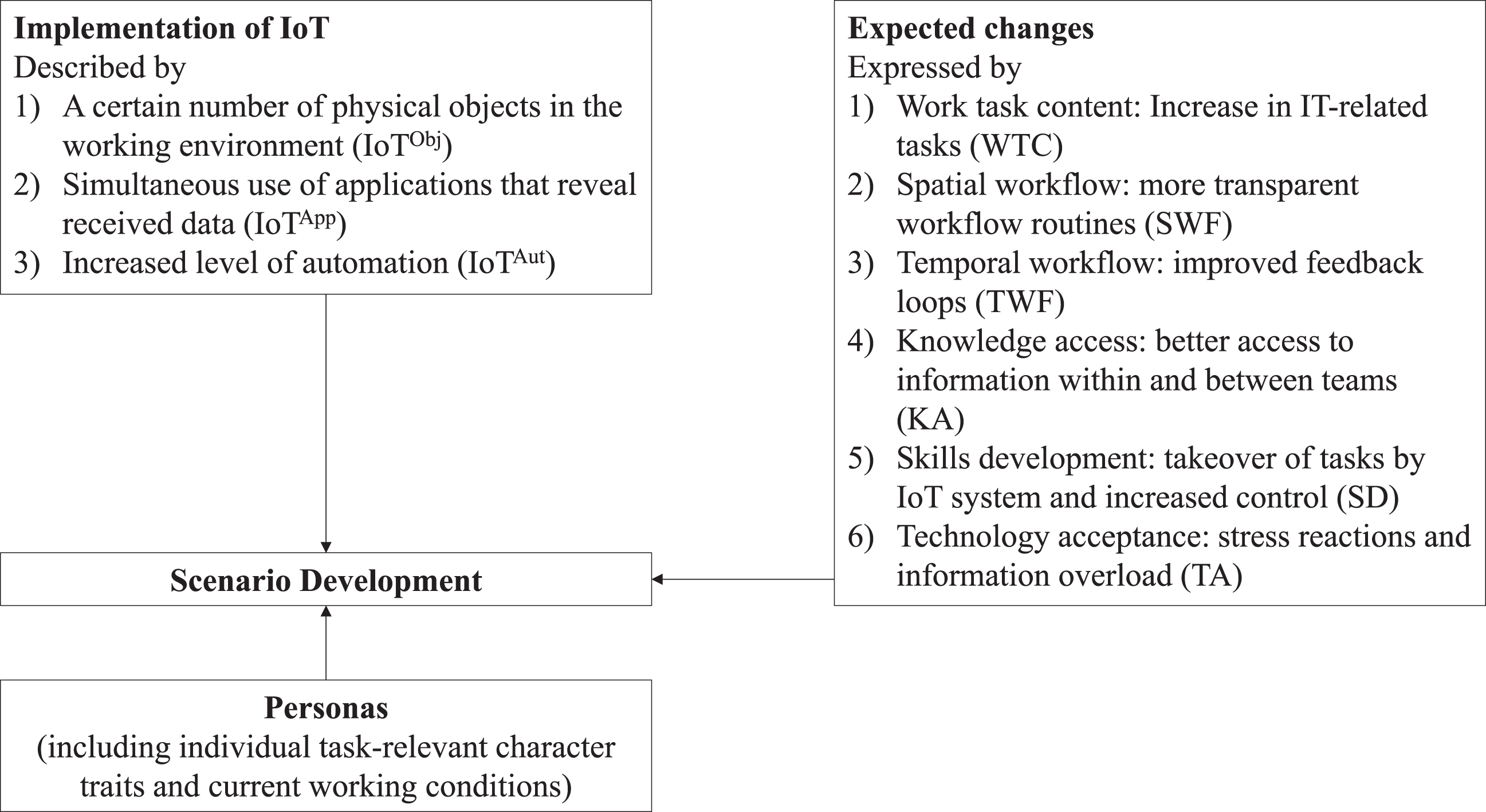

Fig. 2

Scenario development.

To realistically model the scenarios, we relied on 17 in depth, semi-structured interviews with German representatives of industrial organizations of different sizes, consultants, and scientists, which we conducted in person between September and October 2019. The interviewees could be classified into target groups as follows: (1) SMEs, which enabled the personal internal experiences with IoT to be recorded; (2) SME-related associations, which can indicate tendencies of the expected impact of IoT at different levels; (3) consultants, who can enable users to obtain a profound understanding of change processes through the implementation of new technologies in SMEs; and (4) scientists, who can provide qualified statements on the characteristics of IoT technologies with regard to the potential impacts of IoT at different levels. The interviews gave us the opportunity to obtain a comprehensive overview of the impact of IoT in organizations. To gain a deeper understanding of the organizational and individual aspects that are particularly affected by IoT and consequently needed to be included in the scenario development, we derived questions based on the following topics: (1) general descriptives (age, job position); (2) experiences with IoT; (3) organizational changes caused by implementing IoT; (4) individual changes regarding competences, activities or mental states caused by implementing IoT; and (5) requirements to be met when implementing IoT.

The average duration of the interviews was 39.02 minutes (SD = 19.01). At the beginning of each interview, we sought consent for audio recording. Then, we transcribed and coded the interviews via MAXQDA (version 18.2.4) and conducted a stepwise inductive procedure according to Mayring [79]. First, the second and third authors independently analyzed the interviews, constructed categories and then discussed the differences in the coding. Second, the resulting code scheme with different categories was reanalyzed by two other coders. Third, we modified the categories again and created a final code scheme (see Table 1). The table shows the five inductively formed codes and the description of each code. The specification indicates the number of interview statements that were classified into the respective categories (i.e., n1 = no or low impact of IoT; n2 = medium or high impact of IoT). Using the Brennan-Prediger coefficient [80], which is robust to the frequency distribution of the codes to be rated [81], the intercoder agreement was 0.61, which is substantial [82].

Table 1

Coding scheme

| Code | Description | Specification1 | |

| n1 | n2 | ||

| Hierarchy and personnel | Impact of IoT on (1) hierarchical levels and departments, (2) composition of teams, (3) role and influence of the manager. | 34 | 61 |

| Work tasks and job creation | Impact of IoT on (1) work task content, (2) work task distribution, (3) job change. | 6 | 104 |

| Workflows | Impact of IoT on (1) temporal and spatial workflows, (2) flexibility, (3) efficiency and effectiveness, (4) quality engagement, (5) customer engagement | 6 | 163 |

| Skills and knowledge | Impact of IoT on (1) training opportunities, (2) required skills, (3) hard and soft skills development, (4) knowledge access and storage | 63 | 96 |

| Technology acceptance | (1) attitude, openness, and willingness to change, (2) identification with the company, (3) success and creativity, (4) stress, (5) psychological ownership | 60 | 52 |

1n1= no or low impact of IoT; n2= medium or high impact of IoT.

From statements that indicated medium or high potential impacts of IoT, we developed conceptually realistic scenarios, which are presented below. Furthermore, the coding scheme allowed us to draw inference to our third research question (see Chapter 7). On an organizational level, the participants expected that work content would change concerning IT-related aspects (i.e., dealing with IoT devices, data management). At the process level, the respondents suspected that IoT solutions promoted location- and time-independent work coordination, more transparent workflow routines, and improved feedback loops. The respondents stated that IoT can also simplify the monitoring of production and delivery processes (e.g., I_7: “It can, of course, be better used in the value creation process itself. In the translation of data, feedback on the availability of plants or materials insofar as this entire process of capacity provisioning can be improved.”). At the team level, the respondents indicated that although the implementation of IoT would enable better access to information between and within teams, it would lead to increased complexity and extra work in the short- to medium term. At the individual level, the experts expect short- to medium-term stress reactions, information overload, and an increased sense of pressure and control (e.g., I_7: “On the other hand, it will be much faster. The abundance of communication and information is already there, which of course causes the stress to increase”). In conclusion, the responses indicating a medium to high impact of IoT at the organizational, process and individual levels, served in their entirety as the central basis for the development of the scenarios, i.e., the description of the IoT-enabled working environment. Specifically, we used the three key attributes of the IoT mentioned in Chapter 2 in combination with six expected changes in the working environment, derived from the coding scheme, to formulate the scenarios. The figure below provides an overview. For reasons of comprehensibility, we have embedded the applied codes at the corresponding passages in the scenarios in Chapter 5.

4Problem scenarios: Personas in their current working situation

Next, the personas developed in Chapter 3.1 were presented in their working environment. The following description contains the results of the five-step procedure explained in advance.

Steffen, 48 years old, works in the sales/service department of an SME. He completed his training as an industrial clerk and joined the company four years ago. Steffen is characterized by his calmness and strong communication skills. He experiences stress when supply chains collapse, and he is responsible for mistakes despite his diligence. He easily integrates technological changes within the SME into his processes as long as they are meaningful to him. If a new technology does not work and means additional time, his acceptance of the change decreases. His tasks include ordering processes, order confirmations and supplier selection. For this purposes, he requires daily up-to-date information from various departments. Currently working with nonautomated Excel lists, Steffen often lacks an overview of the material inventory. At the same time, he does not have sufficient time to conduct an inventory before each order. This results in incorrect double orders or too few material purchases. Consequently, Steffen must spend an enormous amount of extra time.

Gabriel, 32, completed his training at the SME and has since worked in the company’s production department. He is characterized by diligence and care and prefers clearly formulated tasks. Gabriel experiences stress in a negative working atmosphere under time pressure and when he cannot identify errors himself. Gabriel gets along well with technology, but he is generally skeptical of technological changes as they interrupt his consistency. Therefore, new technological solutions must be intuitive to apply and well explained. His tasks include low-volume production and prototype construction. He completes his tasks in a large hall and can be flexibly deployed between the single working stations. Gabriel is considered the company’s expert on machines and is responsible for ensuring that products meet customers’ requirements. For this purpose, he often compares products from different production lines. This procedure often turns out to be very time-consuming because Gabriel often does not know where the components are located in the company. In addition, he often must search for the right tools as they are often not properly returned to the correct work stations after use. Although there are inventory lists that are filled out by hand, they do not include the storage location.

Marianna, 50 years old, works as an internal logistics specialist in the SME. She has been working for the company for 15 years and is considered a loyal and experienced employee. She stands out for her accurate, neat and reliable way of working. She also shows great interest in the well-being of her colleagues, asks many questions when problems arise and is often perceived as emotional in discussions. Marianna experiences stress when the company’s profitability is at risk or delivery dates are overdue. She has no interest in new technology and openly expresses her skepticism about change to other employees and managers. Her tasks include the authorization and control of the internal flow of goods and materials. She performs her tasks independently and requires minimal consultation with her colleagues. However, in the event of absences due to illness or vacation, Marianna’s department experiences massive additional work and time delays. This is because there is a lack of uniform documentation of tasks and a lack of standardized organization of the materials and products needed. As a result, there is a lack of clarity and traceability.

5Intervention

In the following, we will present an exemplary IoT solution, serving as an intervention to the current working situation of the personas. After that, we will describe the activity, information, and interaction scenarios to answer research questions one and two.

5.1Exemplary IoT solution for SMEs

Based on the interviews conducted, we describe the developed scenarios in the following. These include an exemplary and conceptually elaborated IoT solution (matching the problem scenarios), which is described as follows. As an exemplary IoT solution, we choose to crosslink the storage room that is used by all of the described personas. The storage room is equipped with (1) an interconnected document scanner and (2) sensors on all shelves that record the weight stored. In addition, (3) an RFID reader is installed at the warehouse entrance. It stores data on the employees entering and leaving the warehouse. Only by registering with an employee badge can the door of the warehouse be opened, and the exact times of employee arrivals and departures are stored and transmitted. In addition, (4) exemplary software is implemented to which employees have access that receives the data from the IoT devices. The software can be obtained from all computers and laptops in the company network. We carefully developed the intervention by incorporating the IoT characteristics mentioned in Section 2.1: the document scanner, the sensors and the RFID reader represent the physical objects in the working environment enabling an increased level of automation. The software represents the application that makes the received data available to users. The intervention is a comparatively simple and rather low-complexity IoT solution that is appropriate for SME specifications (i.e., low financial and human resources).

5.2Activity scenario

After implementing the sensors in the storage room (IoTObj), Steffen enters the number of all components currently present as well as the number of components that serves as a minimum (WTC) to cause the sensors to send a notification (IoTAut). Steffen can now retrieve the current stock level over all components in the real storage room at any time (IoTApp). When the program is opened, Steffen receives a warning, for example, that the stock of screws needed for production is running low (IoTApp). The software directs Steffen to the supplier’s website, allowing him to fill his cart with the required components (IoTApp). He submits the order for the screws and generates a reminder, checking later in the day whether he has received an order confirmation (WTC). After starting his shift, Gabriel runs the machines and determines the orders that need to be completed today. For this purpose, he has recently been equipped with a laptop (WTC). On the laptop, all the production orders are listed by calendar day. A variation in production is planned for the second part of his shift. For a smooth transition, he opens all current and past orders in the new software application and filters them according to the desired requirements (IoTApp). On a list of completed orders, Gabriel can now see which materials, templates and tools were used in the past. On the listing, the software application gives him the option to locate the position of all components remaining in the company (SWF). As a shop floor worker, he is able to see the entire inventory and retrieve all of the component locations (IoTAut; SWF). The additional search function on his laptop allows Gabriel to target a reference item and two tools to quickly identify their location in the storage room (IoTApp; SWF). In the storage room, sensors (IoTObj) detect the removal of components, so when colleagues search for a component, they are notified that the component is not currently in the storage room (KA). Therefore, it is necessary for Gabriel to hold his employee ID card against the reader (IoTObj) when entering and leaving the storage room to indicate when he is there. After arriving at the office, Marianna turns on her computer and opens the new software (IoTApp), which gives her an overview of the physical material inflow process (WTC; SWF). Specifically, it shows processes in the receipt and storage of goods as well as consumption or shipping locations (IoTAut). Pending tasks are displayed on a list showing the current processing status and the person processing the task (IoTAut; KA). Thus, Marianna can recognize that one of her colleagues is out of office (SD) and quickly handles an urgent task (KA). After confirming that she has completed the task from her list (SD), Marianna moves on to the stack of letters that arrived at the company today. She leaves her work station and transports the stack to the company’s storage room. First, she places each letter in the document feeder of the interconnected scanner (IoTObj; WTC). Then, she selects the scan template from the saved presets. Marianna starts the scan and then uploads the file to the digital archive inbox, which is part of the new software (IoTApp; WTC). The scanner automatically adds the letter to the “To Do” list (IoTAut), so Marianna and her colleagues can view and edit it digitally (IoTApp; KA; TWF). Here, Marianna can add priority notifications to the scanned letters. Tasks designated as priority 1 are represented with three exclamation marks and displayed at the top of the list. Tasks designated as priority 3 receive only one exclamation mark and appear further down the list (IoTApp; SWF). If Marianna does not add a priority notification, the first-in first-out principle applies, and the scanned documents are reviewed in order (SD). This principle ensures that no tasks are forgotten or completed too late (IoTApp). Once Marianna has finished scanning, she removes the scanned documents from the machine and places them in a filing box. If a document is found not to have been neatly captured, Marianna can return to it. After a few days, the letters are disposed of appropriately (IoTAut).

Fig. 3

Exemplary IoT solution.

5.3Information scenario

The software allows Steffen to view a depiction of a shelf on his computer screen (IoTApp). Using his mouse or the arrows on his keyboard, he views the lower part of the shelf. Above the shelf is a letter icon that lights up in red when there is relevant information for him (IoTAut). When he opens the letter, a box appears informing Steffen that the stock item “screws” is low and needs to be reordered (TWF; SD). He clicks on the word “screws,” and the shelf automatically scrolls to where the screws are stored. Here, in addition to the item number, he can see the current stock level, the delivery time and how many screws have been used per week on average over the last three months (SWF; KA). A sensor on the actual storage room shelf (IoTObj) detects withdrawals of stock and automatically calculates the average (IoTAut). In addition, three symbols can influence the data for the screws. With the help of a “+,” Steffen can manually adjust the number of screws in the event of a sensor error. By clicking on “-,” the number of screws can be corrected downward (WTC; SD). Through the third symbol, which depicts a gear wheel, settings can be made for the article (i.e., weight or volume of a single screw). Furthermore, when reaching a critical value, the program will display a message (IoTAut). By clicking on the supplier of the screws, an order form stored in the program opens in a separate window. This order form contains the data from the last order (SWF), so Steffen only has to make a few changes before sending it (SD). The information stored for many articles saves him a lot of time when reordering (IoTAut; SD). For the second part of Gabriel’s shift in the afternoon, the start of a new order’s production is planned, which requires minor modifications to the machines. As he has high standards for the company’s products, it is important for Gabriel to determine as much as possible about the order in advance. Therefore, he opens the new software on the laptop (IoTApp). In addition to the components that are actually available in the company, the software also displays information about current and past orders (SWF). On his laptop screen, he sees the upper part of a large shelf. In its top tray are two boxes labeled “current orders” and “completed orders”, which are registered in the software by the interconnected scanner (IoTObj). By clicking on the box, a separate window opens in which Gabriel can search for the specific orders he needs. In addition to the option to enter a search term in an empty line, he can apply various filters underneath (i.e., by year, quantity, client) to obtain a more detailed search result (IoTApp; SWF). Gabriel uses the manual search function to find the client. In addition to organizational company data, there is a note stating that the client is very interested in production and frequently contacts the firm about it (TWF; KA). As the client is a long-term customer and his satisfaction is a major priority, Gabriel decides to instruct his colleague from customer care to send a short e-mail to the customer to let him know that production of his order has begun (TWF; KA). Then, Gabriel returns to the list of past orders, reopens the most recent order and begins the reconfiguration of the machine. On Marianna’s screen, the software (IoTApp) shows her the automatically opened list of “tasks to do” at the top. Below that, she sees “completed tasks”; when clicking on that list, the right side of the screen changes to show all tasks in reverse chronological order that have been completed by the internal logistics team in the past (SWF; KA). Symbols and colors indicate which task is being processed by which employee (KA; SD). If Marianna decides to complete the displayed task, the icon of a clock turns blue, and the task is moved to her personal “in progress” list (SWF; KA; SD). A second circle contains a gray checkmark that is highlighted in green when clicked (IoTApp). Thus, every colleague will quickly see that this task has been completed (KA). It disappears from the “tasks to do” or “in progress” list and can now be found again under “completed tasks” (TWF). An exclamation mark indicates the priority level, i.e., how quickly a task should be completed (SWF). In addition, Marianna has the possibility to add tasks herself in the application. For this purpose, a small window opens for entering the name of the task, the priority and notes if additional information is required. By clicking on the “add task” field at the bottom right, the window closes, and the task is added to the list of tasks to be completed, depending on its priority (IoTApp).

5.4Interaction scenario

Steffen routinely opens the new software on the computer to fulfill his tasks (WTC). He feels a strong sense of duty and responsibility for the company’s success. If he oversees critical values or places the wrong order, production downtime or a standstill may result. Of major assistance is the reminder function when stock levels are low (IoTAut). Steffen does not feel controlled, restricted or instructed by the interconnected storage room and the associated software (SD). In addition, the handling is easy for him as he perceives it as self-explanatory and intuitive (TA). His long-standing interest in technology, in both his private and professional life, simplifies new digital processes for him (WTC; TA). For instance, the individual symbols (i.e., letter, plus, minus) that he sees on his screen do not cause him any difficulties in understanding them as he already recognizes them from his smartphone (IoTApp). The familiarity and simplicity of the symbols promote Steffen’s smooth interaction with them. Gabriel needs a reasonable training and adaptation period to use the new software as he perceives the high amount of data as overwhelming (TA). As a result, he initially experienced the new IoT devices and software as cumbersome and time-consuming (TA). As he had difficulties in using the new technology and required a longer time in storage (WTC), Gabriel demonstrated great dissatisfaction at the beginning of TA. In his frustration, he tried to reduce his usage to a minimum (TA). After a period of familiarization, he learned to use the program in a more targeted manner. Especially by entering the search terms more precisely and improving his use of the filters (IoTApp), Gabriel obtained the information that helped him in his work. Over time, the continuous use of the software database became easier and more intuitive, which contributed to improved performance and enhanced customer orientation (SWF). However, Gabriel remains skeptical about the interconnected scanner (IoTObj) that uploads the orders into the software application. He fears that the scanned data could end up on an external server and be misused by third parties (TA). He is still unable to put this fear to rest. Marianna depends on the new software in her daily work (WTC), which causes her discomfort. Especially at the beginning of the program’s implementation, she did not trust it strongly and often completed tasks directly without recording them in the software (TA). Due to the small number of employees and the tight cooperation of the team, Marianna did not see the necessity to mark and sort tasks as tasks. After all, Marianna handles her tasks in a reliable and timely manner without the software. Rather, she fears that the new IoT devices could fail and store data incorrectly (TA). After a colleague was absent for an extended period, she realized the benefits of using the software and the easily obtainable information about her colleague’s tasks (SWF; KA). Here, the personal lists provided clarity and simplified the completion of all the tasks that had been left undone for her. She also learned that the software gives her enough leeway to make her own decisions (SD).

6Results

The scenarios developed provide insights into how the personas, depending on their task-related character traits, react to the implementation of an IoT solution and integrate the system into their established working routine. Table 2 provides an overview and facilitates an improved understanding of the following results section. To present the results in a structured manner, we refer back to the codes introduced in Table 1 (see Chapter 3).

Table 2

Development of structural conditions and recommendations for action

| Steffen Sales/service | Gabriel Production | Marianne Logistics | |

| 1) Task-relevant character traits | –technically enthusiastic | –technically skeptical | –technically not interested |

| –willing to change; however, benefits must be clearly evident | –vulnerable to time pressure | –openly shows (positive and negative) emotions | |

| 2) Current situation | –lack of general overview –high error potential and additional effort | –missing information on production-relevant data –additional effort | –lack of uniform documentation of tasks, materials, etc. –high error potential and additional effort –additional effort and time delays |

| Intervention –Implementation of IoT solution | |||

| (Applying activity scenario; information scenario; interaction scenario) | |||

| 3) Reactions at individual level | - general openness and technical understanding toward the IoT solution | –initial dissatisfaction due to extra time spent working with the IoT solution | –discomfort, fear of causing errors when using the IoT solution(a) |

| –due to initial additional work long-term benefits are not clearly visible | –mental overload due to the large amount of information–fear of possible security issues | - no awareness of the purpose of the IoT system–as a result: low exploitation | |

1) Work task content: A significant increase in IT-related tasks is observed for all personas, representing user groups in different departments. In an administrative working environment (i.e., sales, service, internal logistics), the application, serving as a connector to IoT devices, is particularly exploited. New tasks include the handling of new interfaces and functions as well as the handling of large amounts of data. In an executive working environment (i.e., production), in addition to the application, the IoT devices are mostly effective. Accordingly, additional tasks, such as operating new equipment and an increased level of human–machine interaction, are created. Depending on IT affinity, the changing task content poses immense challenges to users. This includes users being overwhelmed by the data available, afraid of potential errors, and skeptical of potential security vulnerabilities.

2) Spatial workflow: For all personas, the implementation of the IoT system improves the transparency of workflow routines. In both administrative and executive working environments, employees can filter cross-departmental information using the application. For instance, employees gain insights into which tasks or tools were processed or used by which employee at what point in time. In addition, the IoT system simplifies the retrieval of information on past orders, customer information and current processing stages.

3) Temporal workflow: Using the application primarily in an administrative working environment, improved feedback loops mainly result from reminder functions and increased access to customer data. In executive working environments, a stronger effect can be assumed as IoT devices provide direct feedback on tasks (e.g., in the form of error messages).

4) Knowledge access: In administrative working environments, the implementation of IoT facilitates access to knowledge, as employees are able to use the application to track the tasks that need to be completed according to their priority. If a colleague is absent, verbal agreements are not necessarily needed. In executive working environments, for example, there is no need for searching tools or components as they are traceable and easily locatable via the IoT system. However, prior implicit knowledge is not stored in the IoT system; thus, full knowledge access is not to be expected.

5) Skill development: In both administrative and executive working environments, the IoT system handles routine activities, e.g., automatic reminders, reordering, and prioritization. However, the initial setup and operation of the IoT system are time-consuming, especially at the beginning of the implementation phase. Furthermore, in an SME, where quick verbal agreements are readily available, the benefits of an IoT system in relation to the requisite effort are not clearly visible to employees.

6) Technology acceptance: The scenarios reveal that the degree of technology acceptance depends on task-relevant character traits and the resulting usage behavior as well as the perceived benefits of the IoT system. In the scenarios, personas with a lack of IT affinity and negative emotions toward change tend to use the IoT system less or meet it with resistance.

7Implications

To address questions of how IoT implementation affects activities and work practices in SMEs at the individual level and which structural interventions support successful implementation, we developed personas in interviews and created problem-, activity-, information- and interaction scenarios. Based on our analyses, we derived several practical and theoretical implications from the results.

7.1Practical implications

In light of the expected changes in the working environment due to the implementation of the IoT system, the personas, as fictitious user groups in the SME, reveal different individual reactions. As an implication, different organizational conditions are required to enable smooth implementation and long-term use. Possible instruments derived from the literature and in line with our qualitative interview data are discussed in more detail in the text below to answer our third research question.

First, SMEs should prevent discomfort, mental overload, and resistance to the IoT by providing standardized assistance in interacting with the IoT solution. The interview data confirm that stress is increasing due to faster process cycle times and high data availability: “On the other hand, it will be much faster. The abundance of communication and information is already there, which of course increases stress” (interview 7). In addition, almost all 17 interviewees expect resistance within the company to increase (e.g., due to fear of job loss, increase in workload), especially with older employees, who tend to resist more strongly as they have developed successful routines over a long period of time and are reluctant to abandon them. When asked how this problem can be addressed, the respondents stated that an increased understanding of IoT solutions themselves and specific types of assistance are relevant. Thus, the establishment of a support unit is an appropriate instrument for implementing an IoT system. Such a unit consists of specialists (i.e., technology leaders) whose main function is to enhance the adaptability of the organization to new demands [83]. While a support unit needs to be close to management to maintain management support, it should also be familiar with operational IoT issues to ensure successful implementation [84]. The tasks of the support unit should include advising and relieving the management as well as coordinating communication measures and decisions. In addition, the support unit should handle the procurement, implementation and maintenance of the sensors, the training of employees and, if necessary, the procurement of external support. Another task of the support unit is to promote effective networking (i.e., vertical, horizontal, or combination) by opening up the company’s internal innovation system and thus enabling enhanced innovation performance [85]. This enables the continuous advancement and control of IoT implementation. In this context, external knowledge holders can be involved in the development and evaluation processes to provide new perspectives and ideas [86]. In summary, communication and training measures, as well as in-depth knowledge about new IoT systems, are bundled within the support unit.

Second, SMEs should clarify the benefits and purpose of IoT solutions to avoid duplicate or shadow systems and enable the long-term use of the IoT system. The interview data reveal that although the participants are convinced of the added value of IoT, they have some reservations: “(. . .) with IoT technologies and increasing automation, we also have the opportunity to create a world of work where people can do more what they want” (interview 4). It should be transparently demonstrated that existing routines must be disrupted to enable the long-term use of new systems. An appropriate instrument involves clarifying the positive value of new IoT systems to employees, showing them the benefits and supporting them in their use [86, 87]. It is thus recommended that SMEs plan an appropriate testing and adaptation phase. In this stage, employees should receive time slots during their regular working hours to actively engage with the new system and submit feedback, building realistic expectations [88] and allowing for gradual changes to the IoT system. A clearly communicated adoption phase encourages employees to actively participate in shaping future workflows and modifying IoT systems [89]. Furthermore, it strengthens the subsequent acceptance and perceived ease of use of the IoT system [90]. During the adoption phase, we recommend fostering top management support, i.e., company leaders should create a climate of trust, support, and assistance. Acquiring fundamental knowledge about digital processes and applying the acquired knowledge in context- and company-specific situations are also key [91]. In this context, appropriate communication opportunities, training courses and workshops as well as flexible collaboration in cross-disciplinary and cross-company working groups are conducive to effective IoT implementation [70]. In addition, credible, binding behavior by managers is of paramount importance. In their role as mediators, enablers and coordinators, they are responsible for preparing employees for new tasks and responsibilities [70].

Third, and in line with the interview results mentioned above, SMEs should create incentives to motivate (skeptical) employees to use new systems and thus increase the adoption rate. Accordingly, we propose the implementation of internal rewards and recognition structures as an instrument as this adaptation enhances performance and motivation [92] in dealing with new IoT systems. In particular, the introduction of incentive programs, which are highly visible for employees and include social awards and recognition, is suggested [92]. Therefore, it is essential to simultaneously recognize individual performance differences and enable cooperation [92]. A clear target formulation for the use of interconnected IoT devices is appropriate for this purpose; for example, Steffen could receive an e-mail thanking him for his work with the software and expressing praise after 50, 100, and 200 orders executed via the new software. To illustrate the benefits, we recommend publishing a six-month balance sheet showing the financial, personnel and time savings resulting from the implementation of the IoT system based on various parameters.

In conclusion, SMEs can use our recommendations for organizational design to reduce social resistance at an early stage, alleviate fears and ultimately implement IoT solutions successfully. The results provide managers who are planning to implement IoT with an overview of the aspects on which they should focus. In addition, the scenarios illustrate which issues may arise for which particular user group and how they can be avoided during the implementation process. Furthermore, the scenario-based design we use can be applied to other contexts, industries, and company sizes to identify similar solutions. Personas and problem scenarios can be easily developed for related user groups and working activities based on our approach. Activity, information, and interaction scenarios can subsequently be developed to predict how technological solutions will be handled, visualize emerging problems at an early stage, and derive suggestions for improving the current situation. Thus, our results might prevent negative effects of IoT on the mental health of employees, as IoT-based solutions in particular can trigger pressure, anxiety and mental overload.

7.2Theoretical implications

First, we contribute to the management perspective for evaluating the consequences of IoT implementation at the organizational and individual levels. In particular, by assessing the reactions to the introduction of IoT at the individual level and deriving recommendations for action at the organizational level, we make a theoretical contribution to the literature on strategic information system management. By highlighting the consequences, we contribute to the understanding of the intersection between information systems and management and emphasize the relevance of an organizational perspective in the implementation of IoT. Thus, we extend work that focuses on better understanding the role of IoT from a work design perspective [27, 93]. Second, we broaden the perspective on information systems in SMEs by showing how customized user groups deal with new IoT systems and use them in their daily working activities. Depending on specific attributes and characteristics, different effects and requirements arise on an individual level. It can be stated that single process steps can be better tracked and analyzed through IoT; i.e., employees can determine at any time who is working when and where on which substep. However, there is a risk in the correct handling of IoT systems and the lack of a cross-functional understanding of processes. Thus, the identified structural conditions should be implemented to avoid social resistance within the workforce. Third, our findings tie in with the related research. For instance, Cruz, Murphy [94] reveal that increasing automation in the transportation industry contributes to a perceived loss of control, work intensification, and the exploitation of employees. The authors argue for the establishment of health-promoting organizational structures and the avoidance of new sources of work intensification. Accordingly, we extend the findings of Cruz, Murphy [94] by showing that these concerns occur not only in the area of transportation but also among employees in production, logistics, and service.

8Conclusion, limitations and future work

Many organizations expect to gain various benefits from the use of IoT, particularly from increased process efficiency and effectiveness. As shown in the activity, information, and interaction scenarios, IoT systems can help diverse departments retrieve real-time information, automate operational planning, and respond preemptively. As IoT provides employees with improved access to resources, information, and feedback, it supports efficient operations [27]. To successfully implement IoT solutions, companies, especially SMEs, need to actively address organizational changes and empower their employees to deal with technological innovations at an early stage. Psychological states, such as fear, pressure or stress, should be avoided as much as possible. Negative reactions at the individual level can be counteracted by (1) establishing a support unit, (2) planning an appropriate testing and adoption phase, and (3) creating an incentive structure. Therefore, we focused on SMEs with limited financial, human, and time resources, where the employees’ skills contribute significantly to the company’s performance.

To gain insights, the qualitative approach was the most appropriate for gathering information from SMEs and developing realistic personas and scenarios. However, like any academic study, our study suffers from a number of limitations. First, it became apparent that the interview questions could have been better derived through an initial, additional preliminary study. Second, the scenarios were designed using a conceptually developed IoT solution. Although we are optimistic that the activities and issues we derived also occur with other IoT solutions, further studies should attempt to confirm this assumption and cover additional IoT solutions. Third, the research continues to differ on the definition of IoT; as our study took an object-based view of IoT, further empirical studies are needed to identify potential additional individual-level impacts. Moreover, research should be conducted to determine how data can be used effectively without interfering with employee privacy or opening security gaps for companies. Finally, further quantitative studies are required to derive additional implications and recommendations for work practices in the context of IoT.

Acknowledgements

This research paper is funded by the German Federal Ministry of Education and Research (BMBF) and the European Social Fund (ESF) within the program “Future of Work” (funding number 02L18B031) and implemented by the Project Management Agency Karlsruhe (PTKA). The authors are responsible for the content of this publication.

Ethical approval

Not applicable.

Informed consent

Not applicable.

Conflict of interest

The authors declare that they have no conflict of interests.

References

[1] | Brous P , Janssen M , Herder P , The dual effects of the Internet of Things (IoT): A systematic review of the benefits and risks of IoT adoption by organizations, International Journal of Information Management (2020) ;51: , 101952. |

[2] | Sundmaeker H , Guillemin P , Friess P , Woelfflé S , Vision and challenges for realizing the internet of things. Cluster of European Research Projects on the Internet of Things, European Commision. 2010. |

[3] | Xia F , Yang LT , Wang L , Vinel A , Internet of things, International Journal of Communication Systems (2012) ;25: (9):1101–2. |

[4] | Ancarani A , Di Mauro C , Legenvre H , Cardella M , Internet of things adoption: A typology of projects, International Journal of Operations & Production Management (2019) ;40: (6):849–72. |

[5] | Boyes H , Hallaq B , Cunningham J , Watson T , The industrial internet of things (IIoT): An analysis framework, Computers in Industry (2018) ;101: :1–12. |

[6] | Sandu R , Gide E , Investigation of challenges and opportunities for the adoption of cloud-based Internet of things (IoT) in Australian agricultural SME, Global Journal of Information Technology: Emerging Technologies (2017) ;7: (3). |

[7] | Vermanen M , Harkke V , Findings from multipurpose IoT solution experimentations in finnish SMEs: Common expectations and challenges. HICSS. 2019:5246-55. |

[8] | Lopez-Nicolas C , Soto-Acosta P , Analyzing ICT adoption and use effects on knowledge creation: An empirical investigation in SMEs, International Journal of Information Management (2010) ;30: (6):521–8. |

[9] | Miorandi D , Sicari S , De Pellegrini F , Chlamtac I , Internet of things: Vision, applications and research challenges, Ad Hoc Netw (2012) ;10: (7):1497–516. |

[10] | Shin D . A socio-technical framework for Internet-of-Things design: A human-centered design for the Internet of Things, Telematics and Informatics (2014) ;31: (4):519–31. |

[11] | Williams DA , Resources and failure of SMEs: Another look, Journal of Developmental Entrepreneurshi (2014) ;19: (01):1450007. |

[12] | Ferneley E , Sobreperez P , Resist, comply or workaround? An examination of different facets of user engagement with information systems, European Journal of Information Systems (2006) ;15: :345–56. |

[13] | Kim H-W , Kankanhalli A , Investigating user resistance to information systems implementation: A status quo bias perspective, MIS Quarterly (2009) ;33: (3):567–82. |

[14] | Gagné M , Deci E , Self-determination theory and work motivation, Journal of Organizational Behavior (2005) ;26: :331–62. |

[15] | Dragano N , Lunau T , Technostress at work and mental health: Concepts and research results, Current Opinion in Psychiatry (2020) ;33: (4):407–13. |

[16] | La Torre G , Esposito A , Sciarra I , Chiappetta M , Definition, symptoms and risk of techno-stress: A systematic review, International Archives of Occupational and Environmental Health (2019) ;92: (1):13–35. |

[17] | Abeliansky AL , Beulmann M , Are they coming for us? Industrial robots and the mental health of workers. SSRN Electronic Journal. 2019. |

[18] | Kim T , Kang M-Y , Yoo M-s , Lee D-W , Hong Y-C , Computer use at work is associated with self-reported depressive and anxiety disorder. Annals of Occupational and Environmental Medicine. 2016;28. |

[19] | Thibaud M , Huihui C , Wei Z , Selwyn P , Internet of Things (IoT) in high-risk Environment, Health and Safety (EHS) industries: A comprehensive review. Decision Support Systems. 2018;108. |

[20] | Li S , Xu LD , Zhao S , The internet of things: A survey, Information Systems Frontiers (2015) ;17: (2):243–59. |

[21] | Scuotto V , Santoro G , Bresciani S , Del Giudice M , Shifting intra- and inter-organizational innovation processes towards digital business: An empirical analysis of SMEs, Creativity and Innovation Management (2017) ;26: (3):247–55. |

[22] | Lu Y , Papagiannidis S , Alamanos E , Internet of Things: A systematic review of the business literature from the user and organisational perspectives, Technological Forecasting and Social Change (2018) ;136: :285–97. |

[23] | Zaidi A , Faizal M , editors. The IoT Readiness of SMEs in Malaysia: Are they Worthwhile for Investigation? International Conference on International Business, Marketing and Humanities; Alor Setar, Kedah, Malaysia, 2017. |

[24] | Nylander S , Wallberg A , Hansson P , Challenges for SMEs entering the IoT world: Success is about so much more than technology. Proceedings of the Seventh International Conference on the Internet of Things. 2017:1-7. |

[25] | Shin D-H , Conceptualizing and measuring quality of experience of the internet of things: Exploring how quality is perceived by users, Information & Management (2017) ;54: (8):998–1011. |

[26] | Hirzel A-K , Leyer M , Moormann J , The role of employee empowerment in the implementation of continuous improvement: Evidence from a case study of a financial services provider, International Journal of Operations & Production Management (2017) ;37: (10):1563–79. |

[27] | Sievers F , Reil H , Rimbeck M , Stumpf-Wollersheim J , Leyer M , Empowering employees in industrial organizations with IoT in their daily operations, Computers in Industry (2021) ;129: :103445. |

[28] | Leyer M , Stumpf-Wollersheim J , Pisani F , The influence of process-oriented organisational design on operational performance and innovation: A quantitative analysis in the financial services industry, International Journal of Production Research (2017) ;55: (18):5259–70. |

[29] | Rosson MB , Carroll JM , Usability Engineering. Scenario based development of human-computer interaction. Rosson MB, Carroll JM, editors. San Francisco: Morgan Kaufmann; |

[30] | Bardram J , Scenario-based design of cooperative systems, Group Decision and Negotiation (2004) ;9: (3):237–50. |

[31] | Ciriello RF , Richter A , Scenario-based design theorizing, Business & Information Systems Engineering (2019) ;61: (1):31–50. |

[32] | Atzori L , Iera A , Morabito G , Understanding the Internet of Things: Definition, potentials, and societal role of a fast evolving paradigm, Ad Hoc Netw (2017) ;56: :122–40. |

[33] | Mihovska A , Sarkar M , Smart Connectivity for Internet of Things (IoT) Applications. In: Yager RR, Pascual Espada J, editors. New Advances in the Internet of Things. Cham: Springer International Publishing; (2018) , pp. 105–18. |

[34] | Al-Fuqaha A , Guizani M , Mohammadi M , Aledhari M , Ayyash M , Internet of things: A survey on enabling technologies, protocols, and applications, IEEE Communications Surveys & Tutorials (2015) ;17: (4):2347–76. |

[35] | Butala P , Mpofu K , Assembly Systems. In: The International Academy for P, Laperrie`re L, Reinhart G, editors. CIRP Encyclopedia of Production Engineering. Berlin, Heidelberg: Springer Berlin Heidelberg; (2014) , pp. 1–5. |

[36] | Martins L , Varela L , Fernandes N , Carmo-Silva S , Machado J , Literature review on autonomous production control methods, Enterprise Information Systems (2020) ;14: :1–13. |

[37] | Hold P , Erol S , Reisinger G , Sihn W , Planning and evaluation of digital assistance systems, Procedia Manufacturing (2017) ;9: :143–50. |

[38] | Madakam S , Ramaswamy R , Tripathi S , Internet of Things (IoT): A Literature Review, Journal of Computer and Communications (2015) ;3: :164–73. |

[39] | Amendola S , Lodato R , Manzari S , Occhiuzzi C , Marrocco G , RFID technology for IoT-based personal healthcare in smart spaces, IEEE Internet of Things Journal (2014) ;1: (2):144–52. |

[40] | Porter ME , Heppelmann JE , How smart, connected products are transforming competition, Harvard Business Review (2014) ;92: (11):64–88. |

[41] | Markendahl J , Lundberg S , Kordas O , Movin S , On the role and potential of IoT in different industries: Analysis of actor cooperation and challenges for introduction of new technology. 2017 Internet of Things Business Models, Users, and Networks. 2017:1-8. |

[42] | Pingli D , Muthu BA , Kadry SN , Industrial Internet of Things for smart manufacturing applications using Hierarchical Trustful Resource Assignment, Work (2021) ;68: :955–65. |

[43] | Lee I , Lee K , The Internet of Things (IoT): Applications, investments, and challenges for enterprises, Business Horizons (2015) ;58: (4):431–40. |

[44] | Hozdić E , Smart factory for industry 4, A review. Journal of Modern Manufacturing Systems and Technology (2015) ;7: :28–35. |

[45] | Müller-Stewens G , Fleisch E , High-Resolution-Management: Konsequenzen des “Internet der Dinge” auf die Unternehmensführung, Zeitschrift Führung und Organisation (2008) ;77: (5):272–81. |

[46] | Ben-Daya M , Hassini E , Bahroun Z , Internet of things and supply chain management: A literature review, International Journal of Production Research (2017) ;57: :1–24. |

[47] | Ellis S , Morris H , IoT-enabled analytic applications revolutionize supply chain planning and execution. Internation Data Corporation (IDC), White Paper. 2015;13. |

[48] | Sherif KS , Al-Hitmi M , The moderating role of competition and paradoxical leadership on perceptions of fairness towards IoT monitoring. AMCIS 2017 Proceedings. 2017;12. |

[49] | Hytha D , Aronson J , Eng A , Technology innovation and the rebirth of self-regulation: How the internet of things, cloud computing, blockchain, and artificial intelligence solve big problems managing environmental regulation and resources. 2019:5568-72. |

[50] | Zhang Q , Su R , Ryu S , Li C , Yu K , Can work teams prosper with membership flux? The role of team receptivity to newcomers. Academy of Management Proceedings. (2019) ;2019: :17890. |

[51] | Abazi B , An approach to the impact of transformation from the traditional use of ICT to the Internet of Things: How smart solutions can transform SMEs, IFAC-PapersOnLine (2016) ;49: (29):148–51. |

[52] | Hansen EB , Bøgh S , Artificial intelligence and internet of things in small and medium-sized enterprises: A survey, Journal of Manufacturing Systems (2021) ;58: :362–72. |

[53] | Jones N , Graham C , Can the IoT help small businesses? Bulletin of Science, Technology & Society (2020) ;38: (1):3–12. |

[54] | Shin D-I , An exploratory study of innovation strategies of the internet of things SMEs in South Korea, Asia Pacific Journal of Innovation and Entrepreneurshi (2017) ;11: (2):171–89. |

[55] | Trist EL , The evolution of socio-technical systems: Ontario Quality of Working Life Centre Toronto; 1981. |

[56] | Appelbaum SH , Socio-technical systems theory: An intervention strategy for organizational development, Management Decision (1997) ;35: (6):452–63. |

[57] | Bostrom RP , Heinen JS , MIS problems and failures: A socio-technical perspective. Management Information Systems Quarterly. 1977. |

[58] | Oosthuizen R , Pretorius L , Assessing the impact of new technology on complex sociotechnical systems, South African Journal of Industrial Engineering (2016) ;27: (2):15–29. |

[59] | Mumford E , The story of socio-technical design: Reflections on its successes, failures and potential, Information Systems Journal (2006) ;16: (4):317–42. |

[60] | Cunningham J , Farquharson J , Hull D , A profile of the human fears of technological change, Technological Forecasting and Social Change (1991) ;40: :355–70. |

[61] | Ragu-Nathan T , Tarafdar M , Nathan R , Tu Q , The consequences of technostress for end users in organizations: Conceptual development and empirical validation, Information Systems Research (2008) ;19: :417–33. |

[62] | Christensen JO , Finne LB , Garde AH , Nielsen MB , Sørensen K , Vleeshouwes J , The influence of digitalization and new technologies on psychosocial work environment and employee health: A literature review. STAMI-Rapport. 2020. |

[63] | Durst S , The relevance of intangible assets in german SMEs, Journal of Intellectual Capital (2008) ;9: :410–32. |

[64] | Ahmad T , Farrukh F , Nazir S , Capacity building boost employees performance, Industrial and Commercial Training (2015) ;47: (2):61–6. |

[65] | Gul A , Sciences H-M , Zeb J , Apcoms D , Role of capacity development, employee empowerment and promotion on employee retention in the banking sector of pakistan sajjad akbar. 2012;2. |

[66] | Maier C , Personality within information systems research: A literature analysis. ECIS 2012 - Proceedings of the 20th European Conference on Information Systems. 2012. |

[67] | Cheney PH , Lyons NR , Information systems skill requirements: A survey, MIS Q (1980) ;4: (1):35–43. |

[68] | Gîlmeanu R , Theoretical considerations on motivation at the work place, job satisfaction and individual performance, Valahian Journal of Economic Studies (2015) ;6: (3):69–80. |

[69] | Sansone C , Harackiewicz J , Intrinsic and Extrinsic Motivation: The Search for Optimal Motivation and Performance. San Diego: Academic Press; (2000) . |

[70] | Weissman A , Wegerer S , Unternehmen 4.0: Wie Digital isierung Unternehmen & Management verändert. In: Erner M, editor. Management 40 –Unternehmensführung im digitalen Zeitalter. Berlin, Heidelberg: Springer Berlin Heidelberg; (2019) , pp. 43–76. |

[71] | McAdam R , McConvery T , Armstrong G , Barriers to innovation within small firms in a peripheral location, International Journal of Entrepreneurial Behavior & Research (2004) ;10: (3):206–21. |

[72] | von den Eichen SF , Matzler K , Freiling J , Füller J , Woran Geschäftsmodellinnovationen scheitern. In: Granig P, Hartlieb E, Lercher H, editors. Innovationsstrategien: Von Produkten und Dienstleistungen zu Geschäftsmodellinnovationen. Wiesbaden: Springer Fachmedien Wiesbaden; (2014) , pp. 147–59. |

[73] | Vossen RW , Relative strengths and weaknesses of small firms in innovation, International Small Business Journal (1998) ;16: (3):88–94. |

[74] | Vrande V , Jong JPJ , Vanhaverbeke W , Rochemont M , Open innovation in SMEs: Trends, motives and management challenges, Technovation (2009) ;29: :423–37. |

[75] | Antons D , Piller FT , Opening the black box of “not invented here”: Attitudes, decision biases, and behavioral consequences, Academy of Management Perspectives (2015) ;29: (2):193–217. |

[76] | Pruitt JS , Grudin JT , Practice and theory. DUX ’03. 2003:1-15. |

[77] | Urwin E , Venters C , Russell D , Liu L , Luo Z , Webster D , et al., Scenario-based design and evaluation for capability. 2010 5th International Conference on System of Systems Engineering, SoSE, 2010, pp. 1-6. |

[78] | Adlin TJP , The essential persona lifecycle. Your guide to building and using personas. Amsterdamm: Elsevier/Morgan Kaufmann; (2010) . |

[79] | Mayring P , Qualitative Inhaltsanalyse - Grundlagen und Techniken. Weinheim Basel: Beltz Verlag; 2010. |

[80] | Brennan RL , Prediger DJ , Coefficient kappa: Some uses, misuses, and alternatives, Educational and Psychological Measurement (1981) ;41: (3):687–99. |

[81] | Quarfoot D , Levine R , Howrobust are multi-rater inter-rater reliability indices to changes in frequency distribution? The American Statistician. 2016;70. |