The source for ultra-cold neutrons at the FRM II

Abstract

At the Forschungs-Neutronenquelle Heinz Maier-Leibnitz (FRM II) of the Technical University of Munich (TUM) a new source for ultra-cold neutrons (UCN) with a solid deuterium converter is currently under construction. This summary paper shall give an overview of the project and its current status. Research results concerning converter preparation, para-to-ortho conversion, radiation effects and neutron transport, which have been achieved in the last years, are presented and their relevance and transferability for the design of a future UCN source at the European Spallation Source (ESS) are discussed.

1.Introduction

Precision experiments with ultra-cold neutrons [37,63], such as the search for a possible electric dipole moment (EDM) of the neutron [1,46,54] or the measurement of the lifetime

2.Design of the UCN source at the FRM II

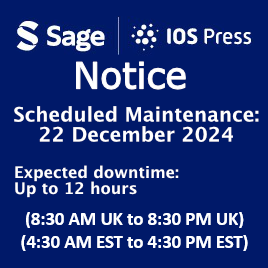

At the FRM II the through-going beam tube SR6 is currently unused. It has one beam port exit at the east side of the experiment hall (called A-side), and one beam port exit in the neutron guide tunnel at the west side (called B-side). This offers the possibility to install all necessary cryogenic supply lines from the B-side, and thus the A-side is completely free for undisturbed extraction of the UCN to connected experiments. The position and the layout of the UCN source is depicted in Fig. 1.

Fig. 1.

Top: vertical cut view of the heavy water vessel and the surrounding concrete shielding (indicated by blue color) of the FRM II along the SR6 beam axis. The cryogenic supply lines for the UCN converter are installed from the left (called B) side. UCN can be extracted to the opposite SR6 A-side through a safety vessel to connected experiments. The UCN converter is placed approximately in the middle of the SR6 beam tube, in a distance of

The central part of the UCN source is the converter vessel, a double-walled toroidal-shaped aluminium cap piece, which is cooled by a continuous flux of a closed supercritical helium cooling loop. The necessary cooling power of up to

3.Solid deuterium as UCN converter material

3.1.Para-to-ortho conversion

Since the inelastic up-scattering cross-section for UCN on para-deuterium

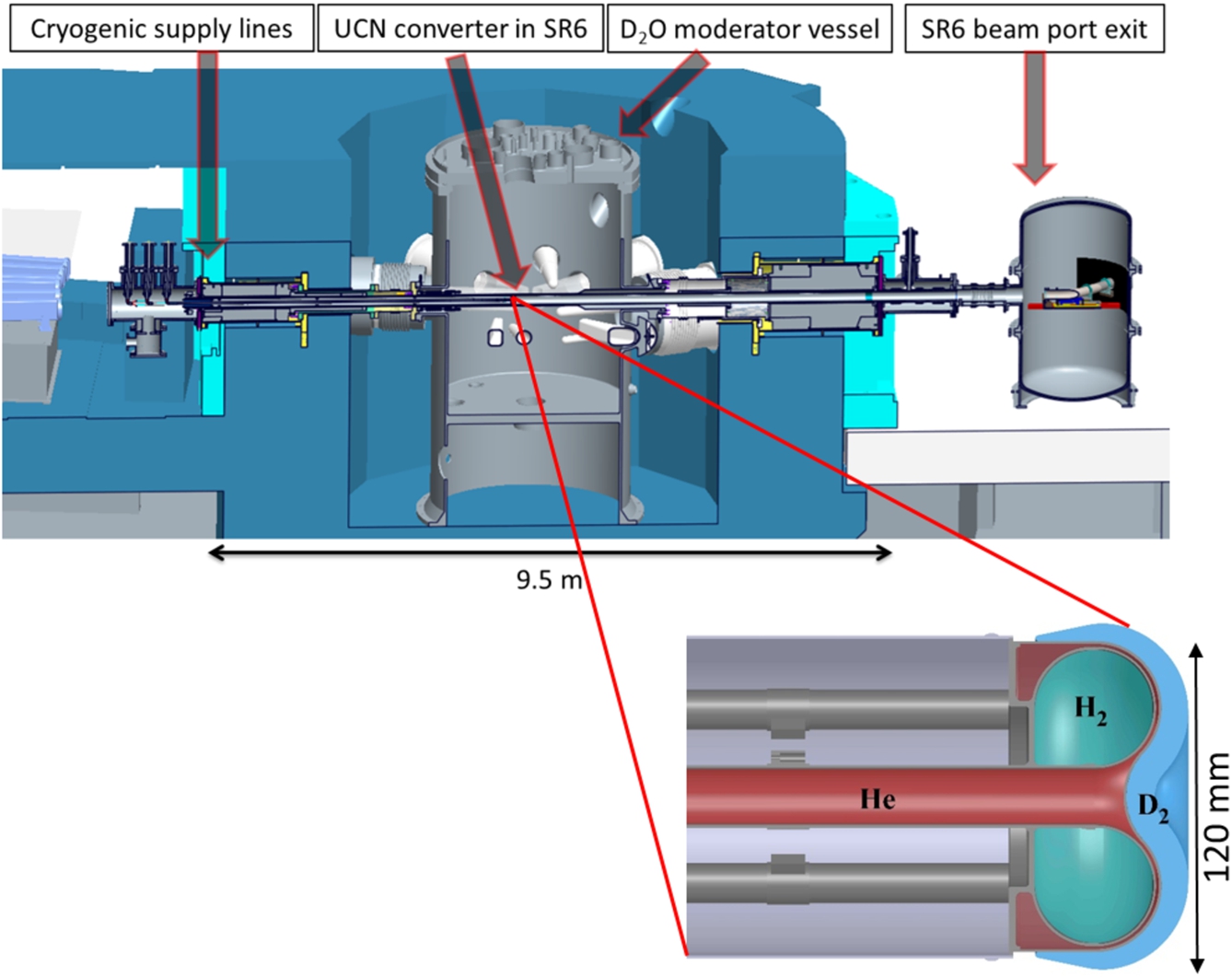

Fig. 2.

Scheme of the para-to-ortho converter using the surface contact of liquid deuterium with OXISORB® grains. The converter cell is mounted on the

3.2.Converter preparation

The preparation of an optically transparent

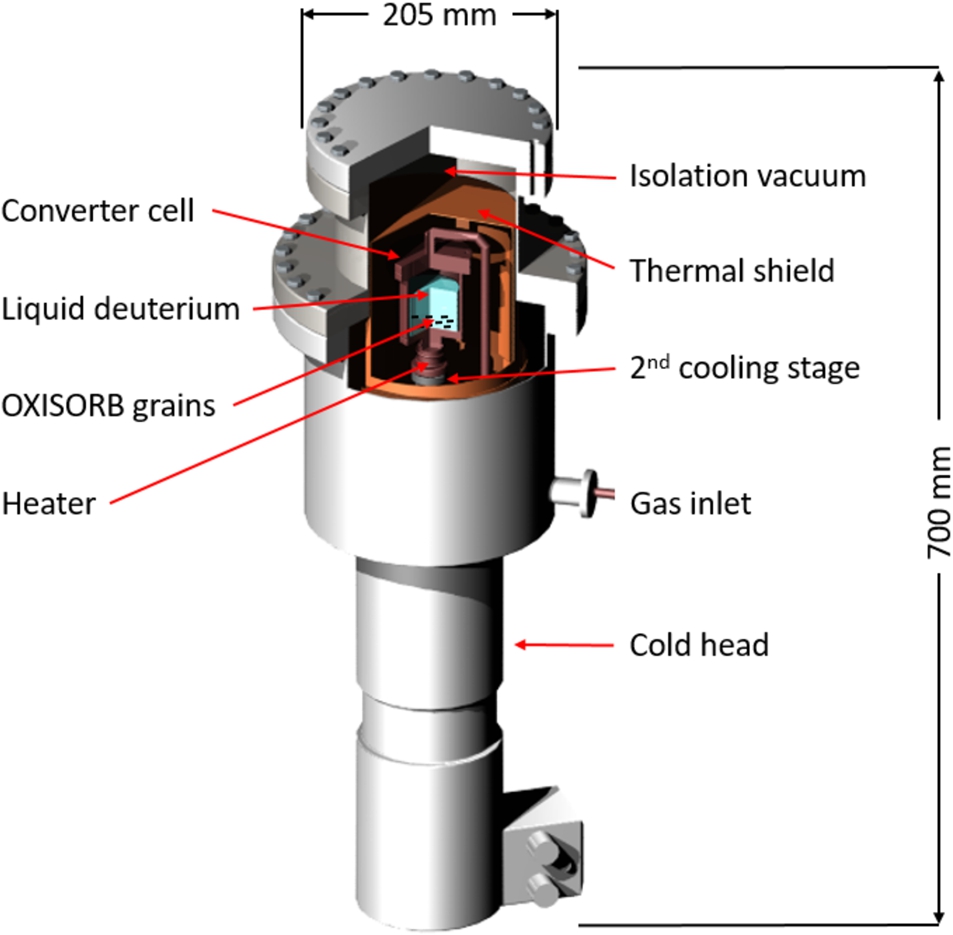

Fig. 3.

a) Solid deuterium frozen out from the liquid phase. b) Solid deuterium frozen out via resublimation from the gaseous phase at

After these preliminary investigations, a

3.3.Radiation-assisted para-to-ortho conversion

Besides by catalytic materials, the ortho-fraction in deuterium can also be increased by irradiation. It is well established that atomic deuterium produced by radiation effects is responsible for the

Any kind of radiation, be it neutron, γ or β radiation, will ionize the deuterium either directly through electromagnetic interactions or indirectly by first colliding with an atom, which then causes ionization. The main ionization processes in deuterium are [62]

Fig. 4.

Left: the

![Left: the J=0 concentration for the t→∞ case in the FRM II UCN source depending on the temperature. Up to 9 K the deuterium will be completely in its ortho state. At higher temperatures the ortho concentrations drop rapidly towards the high temperature equilibrium due to the recombination of deuterium atoms. Right: calculated conversion time constant for a deuterium crystal under irradiation with a dissociation rate of 2.84·10−6 s−1 as expected for the FRM II UCN source. Both figures from [69].](https://content.iospress.com:443/media/jnr/2022/24-2/jnr-24-2-jnr220008/jnr-24-jnr220008-g004.jpg)

4.UCN transport

The efficient transport of UCN from their source to the experimental site is a major issue for various kinds of precision experiments. Neutron guides often have to transport the UCN several tens of meters with acceptable losses. At the FRM II a site dedicated to investigations with UCN is foreseen in an external experimental hall about

UCN can be guided by total reflection in tubes either made of a suitable neutron reflecting material or coated with such a material. The transport is accompanied by many wall reflections and hence the loss probability per wall collision is an important quantity [3,11,14,15,28,33,40,42,43,49,53,61,64,66,71], as well as transport losses by diffuse reflection. As known, for a rough surface the probability of diffuse scattering is approximately given by

One possibility to produce UCN guides with low surface roughness and high neutron optical potential is to fabricate foils via the replication technique (replica guide), which is already used for many years at the Institut Laue-Langevin (ILL) UCN facility [65]. The surface exposed to the UCN is a copy of a float glass surface, onto which a Ni-alloy is deposited by sputtering, reinforced by natural nickel by a galvanic process, and then removed as a foil. For a Ni-alloy replica surface investigated by Plonka et al. [49] the surface roughness was less than

Replica foils for the FRM II are produced by the company S-DH (Sputter-Dünnschichttechnik Heidelberg). They have a maximal surface area of

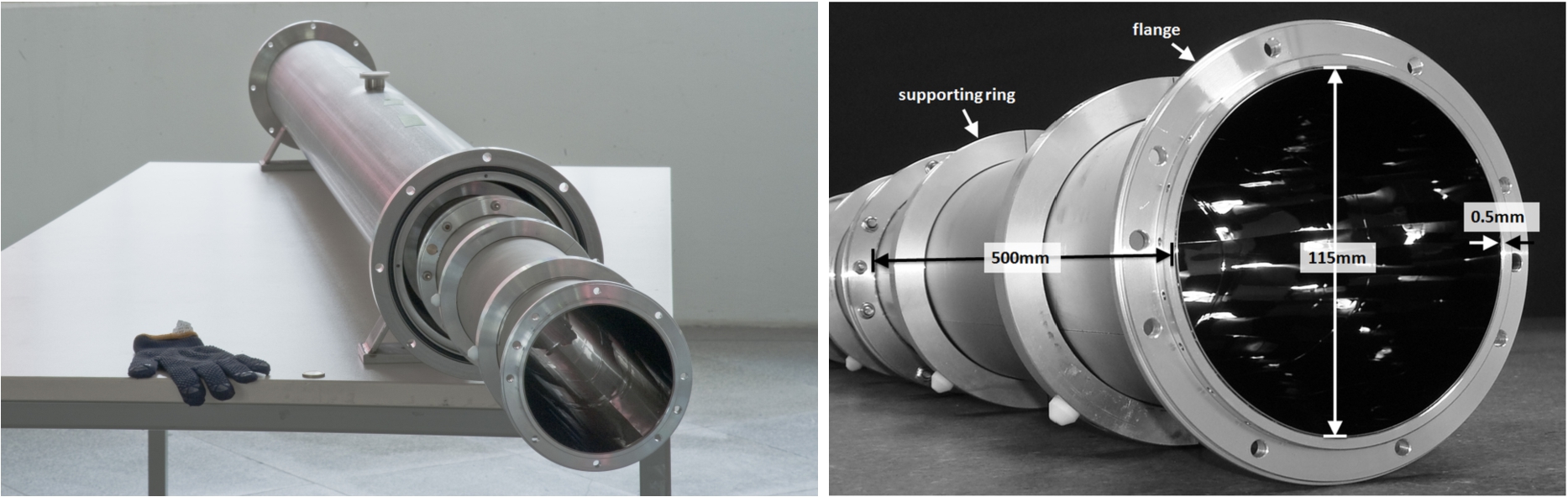

Fig. 5.

Left: a part of a replica foil with its supporting aluminium ring and its flange at the end of the foil is shown. Right: photograph of two connected replica foils with their dimensions.

These guides were experimentally characterized [2,8,20,29]. Thereby the transmission and storage properties have been investigated. The transmission per unit of guide length was measured to be

5.Current status of the FRM II UCN source

The nuclear licensing procedures of the FRM II UCN source require a complete non-nuclear test of all components before their installation and commissioning at the FRM II. Such a test setup of all important components of the UCN source has been installed at the Maier-Leibnitz-Laboratory (MLL), see Fig. 6.

Three vessels, one filled with liquid nitrogen (

A

Fig. 6.

Left: at the south side of the MLL building a

6.Possible impacts for a UCN source at the ESS

At the ESS the development and installation of VCN and UCN sources is planned within the HighNESS project. There are two principle options for a UCN source, an inpile source or a beam source, hereby meaning that an inpile location is inside the ESS monolith (

At all inpile positions the heat input to the converter material and the supporting structures will be significant. Without knowing an exact position or geometry of a future UCN source, a comparison between the FRM II liquid

Considering the case of

Due to the strong irradiation of a

At any inpile position the efficient transport of UCN from the source to an experiment is important, as in this case a distance of several tens of meters has to be passed. The newest generation of replica guides, as described in Section 4, are a valuable option for this purpose. With a transmission probability of

In summary, a small

Acknowledgements

The author thankfully acknowledges the support of innumerable scientists, engineers, technicians and students from the Physics Department E18 of TUM, the Maier-Leibnitz-Laboratory of TUM and LMU, the TRIGA Mainz, the ILL, the University of Applied Sciences Augsburg, the FRM II and the MLZ.

References

[1] | C. Abel et al., Measurement of the permanent electric dipole moment of the neutron, Phys. Rev. Lett. 124: ((2020) ), 081803. doi:10.1103/PhysRevLett.124.081803. |

[2] | I. Altarev, M. Daum, B. Franke, A. Frei, P. Geltenbort, E. Gutsmiedl, F.J. Hartmann, S. Materne, A.R. Müller, R. Picker, K. Schreckenbach and R. Stoepler, ILL experimental report 3-14-250, 2008. |

[3] | I. Altarev, A. Frei, P. Geltenbort, E. Gutsmiedl, F.J. Hartmann, A.R. Müller, S. Paul, C. Plonka and D. Tortorella, A method for evaluating the transmission properties of ultracold-neutron guides, Nucl. Instrum. and Meth. A 570: ((2007) ), 101. doi:10.1016/j.nima.2006.09.104. |

[4] | A. Anghel et al., The PSI ultra-cold neutron source, Nucl. Instrum. Meth. Phys. Res. A 611: ((2009) ), 272. doi:10.1016/j.nima.2009.07.077. |

[5] | A. Anghel et al., Solid deuterium surface degradation at ultracold neutron sources, Eur. Phys. J. A 54: ((2018) ), 148. doi:10.1140/epja/i2018-12594-2. |

[6] | S. Arzumanov, L. Bondarenko, S. Chernyavsky, P. Geltenbort, V. Morozov, V.V. Nesvizhevsky, Y. Panin and A. Strepetov, A measurement of the neutron lifetime using the method of storage of ultracold neutrons and detection of inelastically up-scattered neutrons, Phys. Lett. B 745: ((2015) ), 79. doi:10.1016/j.physletb.2015.04.021. |

[7] | F. Atchison et al., Ortho-para equilibrium in a liquid |

[8] | L. Beck, T. Deuschle, A. Frei, P. Geltenbort, T. Huber, K. Schreckenbach, R. Stoepler and S. Wlokka, Ill experimental report 3-14-287, 2010. |

[9] | Y. Beßler, Moderator cooling at ESS, HighNESS / LENS workshop on Very Cold and Ultra Cold Sources for ESS, 2022. |

[10] | G. Bison et al., Comparison of ultracold neutron sources for fundamental physics measurements, Phys. Rev. C 95: ((2017) ), 045503. doi:10.1103/PhysRevC.95.045503. |

[11] | B. Blau, M. Daum, M. Fertl, P. Geltenbort, L. Göltl, R. Henneck, K. Kirch, A. Knecht, B. Lauss, P. Schmidt-Wellenburg and G. Zsigmond, A prestorage method to measure neutron transmission of ultracold neutron guides, Nucl. Instrum. and Meth. A 807: ((2016) ), 30. doi:10.1016/j.nima.2015.10.075. |

[12] | K. Bodek et al., An apparatus for the investigation of solid |

[13] | G.W. Collins, E.M. Fearon, E.R. Mapoles, R.T. Tsugawa, P.C. Souers and P.A. Fedders, |

[14] | M. Daum et al., Transmission of ultra-cold neutrons through guides coated with materials of high optical potential, Nucl. Instrum. and Meth. A 741: ((2014) ), 71. doi:10.1016/j.nima.2013.12.050. |

[15] | M. Daum, A. Frei, P. Geltenbort, E. Gutsmiedl, P. Höbel, H.-C. Koch, A. Kraft, T. Lauer, A.R. Müller, S. Paul and G. Zsigmond, A low-pass velocity filter for ultracold neutrons, Nucl. Instrum. and Meth. A 675: ((2012) ), 103. doi:10.1016/j.nima.2012.02.007. |

[16] | V.F. Ezhov et al., Measurement of the neutron lifetime with ultracold neutrons stored in a magneto-gravitational trap, JETP Lett. 107: ((2018) ), 671. doi:10.1134/S0021364018110024. |

[17] | A. Frei, Produktion von ultrakalten Neutronen mit einem festen Deuteriumkonverter, Ph.D. Dissertation, Technical University of Munich, 2008. |

[18] | A. Frei et al., First production of ultracold neutrons with a solid deuterium source at the pulsed reactor TRIGA Mainz, Eur. Phys. J. A 34: ((2007) ), 119. doi:10.1140/epja/i2007-10494-2. |

[19] | A. Frei, E. Gutsmiedl, C. Morkel, A.R. Müller, S. Paul, S. Rols, H. Schober and T. Unruh, Understanding of ultra-cold-neutron production in solid deuterium, Europhysics Letters 92: ((2010) ), 62001. doi:10.1209/0295-5075/92/62001. |

[20] | A. Frei, K. Schreckenbach, B. Franke, F.J. Hartmann, T. Huber, R. Picker, S. Paul and P. Geltenbort, Transmission measurements of guides for ultra-cold neutrons using UCN capture activation analysis of vanadium, Nucl. Instrum. and Meth. A 612: ((2010) ), 349. doi:10.1016/j.nima.2009.10.101. |

[21] | R. Garoby et al., The European Spallation Source design, Phys. Scr. 93: ((2018) ), 014001. doi:10.1088/1402-4896/aa9bff. |

[22] | R. Garoby et al., Corrigendum: The European Spallation Source design (2018 Phys. Scr. 93 014001), Phys. Scr. 93: ((2018) ), 129501. doi:10.1088/1402-4896/aaecea. |

[23] | R. Golub and J.M. Pendlebury, Super-thermal sources of ultra-cold neutrons, Phys. Lett. A 53: ((1975) ), 133. doi:10.1016/0375-9601(75)90500-9. |

[24] | R. Golub and J.M. Pendlebury, The interaction of Ultra-Cold Neutrons (UCN) with liquid helium and a superthermal UCN source, Phys. Lett. A 62: ((1977) ), 337. doi:10.1016/0375-9601(77)90434-0. |

[25] | F.M. Gonzalez et al., Improved neutron lifetime measurement with UCNτ, Phys. Rev. Lett. 127: ((2021) ), 162501. doi:10.1103/PhysRevLett.127.162501. |

[26] | B.Y. Gorodilov, I.N. Krupskii and V.G. Manzhelii, Sov. J. Low Temp. Phys. 3: ((1977) ), 1562. |

[27] | B.Y. Gorodilov, I.N. Krupskii, V.G. Manzhelii and O.A. Korolyuk, Sov. J. Low Temp. Phys. 7: ((1981) ), 424. |

[28] | S. Heule et al., Diamond-like carbon coated ultracold neutron guides, Appl. Surf. Sci. 253: ((2007) ), 8245. doi:10.1016/j.apsusc.2007.02.139. |

[29] | T. Huber, Transport and storage of ultra-cold neutrons in replika-guides, Diploma thesis, Technical University of Munich, 2011. |

[30] | T.M. Ito et al., Performance of the upgraded ultracold neutron source at Los Alamos National Laboratory and its implication for a possible neutron electric dipole moment experiment, Phys. Rev. C 97: ((2018) ), 012501. doi:10.1103/PhysRevC.97.012501. |

[31] | J. Karch, Y. Sobolev, M. Beck, K. Eberhardt, G. Hampel, W. Heil, R. Kieser, T. Reich, N. Trautmann and M. Ziegner, Performance of the solid deuterium ultra-cold neutron source at the pulsed reactor TRIGA Mainz, Eur. Phys. J. A 50: ((2014) ), 78. doi:10.1140/epja/i2014-14078-9. |

[32] | E. Korobkina, B.W. Wehring, A.I. Hawari, A.R. Young, P.R. Huffman, R. Golub, Y. Xu and G. Palmquist, An ultracold neutron source at the NC State University PULSTAR reactor, Nucl. Instrum. and Meth. A 579: ((2007) ), 530. doi:10.1016/j.nima.2007.04.116. |

[33] | K.J. Kügler, W. Paul and U. Trinks, Properties of straight and curved neutron guide tubes, Z. Phys. B 39: ((1980) ), 361. doi:10.1007/BF01305837. |

[34] | T. Lauer and T. Zechlau, A prospective pulsed source of ultracold neutrons for experiments in fundamental neutron physics, Eur. Phys. J. A 49: ((2013) ), 104. doi:10.1140/epja/i2013-13104-x. |

[35] | B. Lauss and B. Blau, UCN, the ultracold neutron source – neutrons for particle physics, SciPost Phys. Proc. 5: ((2021) ), 004. doi:10.21468/SciPostPhysProc.5.004. |

[36] | C.-Y. Liu, A.R. Young and S.K. Lamoreaux, Ultracold neutron upscattering rates in a molecular deuterium crystal, Phys. Rev. B 62: ((2000) ), R3581. doi:10.1103/PhysRevB.62.R3581. |

[37] | V.I. Lushchikov, Y.N. Pokotilovskii, A.V. Strelkov and F.L. Shapiro, JETP Lett. 9: ((1969) ), 23. |

[38] | J. Martin, B. Franke, K. Hatanaka, S. Kawasaki and R. Picker, The TRIUMF UltraCold advanced neutron source, Nuclear Physics News 31: ((2021) ), 19. doi:10.1080/10619127.2021.1881367. |

[39] | Y. Masuda, K. Hatanaka, S.-C. Jeong, S. Kawasaki, R. Matsumiya, K. Matsuta, M. Mihara and Y. Watanabe, Spallation ultracold neutron source of superfluid helium below 1 K, Phys. Rev. Lett. 108: ((2012) ), 134801. doi:10.1103/PhysRevLett.108.134801. |

[40] | W. Maysenhölder, Effect of a sharp bend on the transmission of neutron guide tubes of circular cross section, Nucl. Instrum. Meth. 137: ((1976) ), 291. doi:10.1016/0029-554X(76)90340-2. |

[41] | A.R. Müller, Characterization of solid |

[42] | V.V. Nesvizhevsky, Polished sapphire for ultracold-neutron guides, Nucl. Instrum. and Meth. A 557: ((2006) ), 576. doi:10.1016/j.nima.2005.10.024. |

[43] | V.V. Nesvizhevsky et al., Comparison of specularly reflecting mirrors for GRANIT, Nucl. Instrum. and Meth. A 578: ((2007) ), 435. doi:10.1016/j.nima.2007.05.319. |

[44] | D. Päthe, Kalte Quelle mit Hilfseinrichtungen JBB10, QKQ20, JBB30, JBB40, QVQ50, QVQ60/6S, QKE80, CPQ, Forschungs-Neutronenquelle Heinz Maier-Leibnitz (FRM II), 2015. |

[45] | R.W. Pattie Jr. et al., Measurement of the neutron lifetime using a magneto-gravitational trap and in situ detection, Science 360: ((2018) ), 627. doi:10.1126/science.aan8895. |

[46] | J.M. Pendlebury et al., Revised experimental upper limit on the electric dipole moment of the neutron, Phys. Rev. D 92: ((2015) ), 092003. doi:10.1103/PhysRevD.92.092003. |

[47] | A. Pichlmaier, V. Varlamov, K. Schreckenbach and P. Geltenbort, Neutron lifetime measurement with the UCN trap-in-trap MAMBO II, Phys. Lett. B 693: ((2010) ), 221. doi:10.1016/j.physletb.2010.08.032. |

[48] | F.M. Piegsa, M. Fertl, S.N. Ivanov, M. Kreuz, K.K.H. Leung, P. Schmidt-Wellenburg, T. Soldner and O. Zimmer, New source for ultracold neutrons at the institut Laue-Langevin, Phys. Rev. C 90: ((2014) ), 015501. doi:10.1103/PhysRevC.90.015501. |

[49] | C. Plonka, P. Geltenbort, T. Soldner and H. Häse, Replika mirrors – nearly loss-free guides for ultracold neutrons – measurement technique and first preliminary results, Nucl. Instrum. and Meth. A 578: ((2007) ), 450. doi:10.1016/j.nima.2007.05.314. |

[50] | J.D. Sater, J.R. Gaines, E.M. Fearon, P.C. Souers, F.E. McMurphy and E.R. Mapoles, Ortho-to-para conversion in solid tritium. II. Experimental values, Phys. Rev. B 37: ((1988) ), 1482. doi:10.1103/PhysRevB.37.1482. |

[51] | V.F. Sears, Neutron scattering lengths and cross sections, Neutron News 3: ((1992) ), 26. doi:10.1080/10448639208218770. |

[52] | A. Serebrov et al., Measurement of the neutron lifetime using a gravitational trap and a low-temperature Fomblin coating, Phys. Lett. B 605: ((2005) ), 72. doi:10.1016/j.physletb.2004.11.013. |

[53] | A.P. Serebrov et al., Ultracold-neutron infrastructure for the PNPI/ILL neutron EDM experiment, Nucl. Instrum. and Meth. A 611: ((2009) ), 263. doi:10.1016/j.nima.2009.07.084. |

[54] | A.P. Serebrov et al., New search for the neutron electric dipole moment with ultracold neutrons at ILL, Phys. Rev. C 92: ((2015) ), 055501. doi:10.1103/PhysRevC.92.055501. |

[55] | A.P. Serebrov et al., J. Phys.: Conf. Ser. 798: ((2017) ), 012147. |

[56] | A.P. Serebrov et al., Neutron lifetime measurements with a large gravitational trap for ultracold neutrons, Phys. Rev. C 97: ((2018) ), 055503. doi:10.1103/PhysRevC.97.055503. |

[57] | A.P. Serebrov, A.K. Fomin, M.S. Onegin, A.G. Kharitonov, D.V. Prudnikov, V.A. Lyamkin and S.A. Ivanov, The project of ultracold neutron sources at the PIK reactor with superfluid helium as a moderator, Tech. Phys. Lett. 40: ((2014) ), 10. doi:10.1134/S1063785014010118. |

[58] | A.P. Serebrov, V.A. Mityukhlyaev, A.A. Zakharov, V.V. Nesvizhevsky and A.G. Kharitonov, JETP Lett. 59: ((1994) ), 757. |

[59] | V. Shevtsov, A. Frolov, I. Lukashevich, E. Ylinen, P. Malmi and M. Punkkinen, The ortho-to-para conversion in solid hydrogen, catalyzed by hydrogen atoms, J. Low Temp. Phys. 95: ((1994) ), 815. doi:10.1007/BF00754716. |

[60] | I.F. Silvera, The solid molecular hydrogens in the condensed phase: Fundamentals and static properties, Rev. Mod. Phys. 52: ((1980) ), 393. doi:10.1103/RevModPhys.52.393. |

[61] | Y. Sobolev et al., Cubic boron nitride: A new prospective material for ultracold neutron application, Nucl. Instrum. and Meth. A 614: ((2010) ), 461. doi:10.1016/j.nima.2009.12.035. |

[62] | P.C. Souers, Hydrogen Properties for Fusion Energy, University of California Press, (1986) . |

[63] | A. Steyerl, Measurements of total cross sections for very slow neutrons with velocities from 100 m/sec to 5 m/sec, Phys. Lett. B 29: ((1969) ), 33. doi:10.1016/0370-2693(69)90127-0. |

[64] | A. Steyerl, Effect of surface roughness on the total reflexion and transmission of slow neutrons, Z. Phys. A 254: ((1972) ), 169. doi:10.1007/BF01380066. |

[65] | A. Steyerl, H. Nagel, F.X. Schreiber, K.A. Steinhauser, R. Gähler, W. Gläser, P. Ageron, J.M. Astruc, W. Drexel, G. Gervais and W. Mampe, A new source of cold and ultracold neutrons, Phys. Lett. A 116: ((1986) ), 347. doi:10.1016/0375-9601(86)90587-6. |

[66] | M. Utsuro and K. Okumura, Production and guide tube transmission of very cold neutrons from pulsed cold source, J. Nucl. Sci. Technol. 19: ((1982) ), 863. doi:10.1080/18811248.1982.9734232. |

[67] | D.H. Weitzel, W.V. Loebenstein, J.W. Draper and O.E. Park, Ortho-para catalysis in liquid-hydrogen production, J. Res. Natl. Bur. Stand. 60: ((1958) ), 221. doi:10.6028/jres.060.026. |

[68] | S. Wlokka, Kryo-Konvertermaterialien zur Erzeugung ultrakalter Neutronen und Untersuchungen an Testaufbauten der neuen UCN-Quelle am FRM II, Diploma thesis, Technical University of Munich, 2011. |

[69] | S. Wlokka, Aspects of ultra-cold neutron production in radiation fields at the FRM II, Ph.D. Dissertation, Technical University of Munich, 2016. |

[70] | Z.-C. Yu, S.S. Malik and R. Golub, A thin film source of ultra-cold neutrons, Z. Phys. B 62: ((1986) ), 137. doi:10.1007/BF01323423. |

[71] | T. Zechlau, Ultra-cold neutron transport and spin manipulation system for the measurement of the neutron electric dipole moment, Ph.D. Dissertation, Technical University of Munich, 2016. |

[72] | O. Zimmer, K. Baumann, M. Fertl, B. Franke, S. Mironov, C. Plonka, D. Rich, P. Schmidt-Wellenburg, H.-F. Wirth and B. van den Brandt, Superfluid-helium converter for accumulation and extraction of ultracold neutrons, Phys. Rev. Lett. 99: ((2007) ), 104801. doi:10.1103/PhysRevLett.99.104801. |

[73] | O. Zimmer, F.M. Piegsa and S.N. Ivanov, Superthermal source of ultracold neutrons for fundamental physics experiments, Phys. Rev. Lett. 107: ((2011) ), 134801. doi:10.1103/PhysRevLett.107.134801. |