Effect of chitosan-olive oil emulsion coating on quality of tomatoes during storage at ambient conditions

Abstract

BACKGROUND:

Tomato, a berry with a high nutritional content, is one of the most important vegetables due to its commercial importance, easy manipulation and rapid production cycle. The application of biodegradable films and coatings as alternative preservation method, provides a protective layer and creates a modified atmosphere in the fruit.

OBJECTIVE:

The aim of the present study was to evaluate the influence of chitosan-olive oil coatings on the quality of tomatoes cv. Charleston during their storage at 27±1°C and 80% RH.

METHODS:

According with the treatments, chitosan at 1 and 2% (w/v) in 1% (v/v) of lactic acid was dissolved by stirring during 2 h at 40°C and then was emulsified with olive oil at 2 and 4% (v/v).

RESULTS:

Tomatoes coated with chitosan at 2% (w/v) with 2 and 4% (v/v) of olive oil presented the higher weight losses.

CONCLUSIONS:

Coatings from chitosan-olive oil emulsion delayed the ripening and maintained the firmness of tomatoes cv. Charleston with respect to uncoated fruits during storage, although these coatings did not act as an effective barriers against the weight loss. These results can be helpful for horticulturists and agro-food products distributors, as well as for the postharvest technologists.

1Introduction

In recent decades the production and consumption of fruits and vegetables has greatly increased worldwide [1]. In this context, the tomato fruit is one of the most important products due to its commercial importance, easy manipulation and rapid cycle of production [2]. Tomato fruit is a berry with a high nutritional content [3], whose postharvest losses in developing countries range from 25 to 50% of the production as a result of physiological disorders and lack of adequate storage technologies to control ripening and senescence. The application of edible films and coatings that provides a protective layer and creates a modified atmosphere in the fruit, is one of the novel methods of preservation that focuses the attention of food industry in recent years [4].

Films and edible coatings based on biomolecules have created new concepts in packaging. These biomolecules include polysaccharides such as chitosan [5], widely used due to its films properties, good biocompatibility, biodegradability and low cost [6]. Moreover, chitosan offers a high potential for obtaining edible coatings and films because of its excellent oxygen barrier property [7].

Chitosan is mainly the deacetylated form of chitin and a molecule consists of 2-amino-2-deoxy-β-D-glucose [8]. The numerous applications of chitosan and its derivatives in the food industry include its use as a flocculating agent, clarifying substance, thickening substance, gas selective membrane, coating material, wound-healing factor agent and antimicrobial agent [5]. In whole or cut fruits it is used to extend shelf life by reducing moisture loss, breathing and color changes [9]. It can also be employed as a vehicle for functional ingredients, forming nutraceuticals foods [10]. Another interesting property in relation to food packaging is its ability to absorb heavy metal ions [11], which is used to decrease oxidative processes catalyzed by free metals in foods [12]. Its application as antioxidant has been exploited in the conservation of strawberries and other fruits [13].

Considering the usability offered by chitosan and the importance that represents the application of coatings and biodegradable films as alternative methods for the preservation of fruit and vegetables, in the present study the influence of chitosan-olive oil coatings on tomatoes (Lycopersicum esculentum Mill) quality during storage at ambient conditions was evaluated.

2Materials and methodology

2.1Materials used

The materials used to prepare the coating-forming emulsions were: chitosan, obtained at the Center for Drug Research and Development, by N-deacetylation of chitin from common lobster (Panulirus argus) with a degree of deacetylation; approximately of 80% ; extra virgin olive oil (Carbonell, Spain) as plasticizer; 90% lactic acid (Merck, Germany) and distilled water.

Tomatoes (L. esculentum Mill) cv. Charleston, grown on a farm at west of Havana, were harvested in the breaker stage [14]. They were selected in a manner that all fruits presented the same characteristics of size, absence of visible defects, homogeneous and uniform ripening stage and then divided into lots according to the treatments performed.

All fruits were washed with tap water, sanitized with a sodium hypochlorite solution (80 mg/L), dried at ambient temperature and relative humidity (27±1°C and 81% RH) and characterized through the evaluation of moisture content, percent of soluble solids, titrable acidity, pH, ripening index and firmness.

2.2Preparation of chitosan coating-forming emulsions

Chitosan solutions at 1 and 2% (w/v) were prepared in a 1% (v/v) solution of lactic acid [8], and mixed with a magnetic stirrer for 2 h at 40°C. Then olive oil was added at 2 and 4% (v/v) to both chitosan solutions at 1 and 2% (w/v), respectively. This mixture was emulsified at 13500 rpm for 4 min [15]. Table 1 shows the experimental design for coating-forming emulsions.

2.3Application of coatings

Experiments were performed on lab scale using 20 tomatoes for each treatment. Tomatoes from the batch control (without coating) were immersed in distilled water and kept under the same storage conditions than treated tomatoes for comparing the variations of quality attributes (weight loss, classification according to ripening stage, soluble solids, titratable acidity, pH, moisture content, firmness and visible deterioration).

Coatings were applied by double immersion of the fruits in the coating-forming emulsions during one minute each time. Tomatoes were dried during 30 min between the immersions. Drying was carried out in stainless steel grills subjected to forced airflow at 27±1°C and 80% RH.

2.4Storage and sampling

Coated and uncoated tomatoes were placed in plastic boxes and stored at 27±1°C and 80% RH [2] during 21 days. Evaluations of quality attributes were performed at day 0 and 3, 5, 7, 10, 12, 14, 16, 19 and 21 days of storage.

2.5Quality attributes

2.5.1Classification according to ripening stages

Tomatoes were classified according to their ripening stage using a visual scale [16], in which, the extremes, one and seven, represent green and red colors, respectively. The results were expressed as percentage of tomatoes in each ripening stage with respect to the all fruits conforming the treatment.

2.5.2Texture analysis

Firmness was determined by a penetrometer with a 30° cone angle (AH Thomas Co. USA). The mass of the cone assembly was 150 g and the penetration time used was 5 s [8]. Firmness was measured as the maximum penetration distance during penetration time.

2.5.3Determination of soluble solids, pH and titratable acidity

The soluble solids content was determined in the juice of tomatoes by triplicate in an Abbe refractometer [17] and the result was reported as °Brix. The pH was assessed using a potentiometer (Basic 20, Crison) [18]. The titratable acidity was made by a volumetric method of neutralization [19]. The results were expressed as % w/w of the majority acid. All determinations were performed in triplicate, reporting the mean value.

2.5.4Relationship of soluble solids/acidity during storage

The relationship of soluble solids/acidity percentage was calculated as a measure of the flavor of tomatoes. The values of this relationship were multiplied by ten to facilitate the graphic interpretation of this indicator during the storage of tomatoes.

2.5.5Weight loss and moisture content

Weight losses of tomatoes during storage were determined on labelled fruits for each treatment by the gravimetric method using a technical scale, and the results were expressed as percentage of weight loss at each time of evaluation from the initial weight.

Moisture content was performed by indirect gravimetry with volatilization, by separating the product water by oven drying at 105°C, to constant weight [20].

2.5.6Physiological decay

Physiological deterioration was visually inspected at the end of storage. It was determined by the evaluation of the skin dehydration levels (D1, D2, D3, and D4), which correspond to the following ranges: D1, up to 10% of dehydrated surface; D2, up to 30% of dehydrated surface; D3, more than 30% of dehydrated surface and D4, overripe with visible fungal decay.

The tomatoes that showed a D3 dehydration level on the surface were considered seriously damaged. Results were expressed as a percentage of damaged fruits [2].

2.6Analysis of results

It was performed the ANOVA test by using STATISTICS software (version 7, 2004, StatSoft. Inc., Tulsa, USA) and the Duncan’s multiple range test was used for determining statistical difference between the treatments. The significance was defined at p≤0.05.

3Results

3.1Characterization of tomato fruits

The Table 2 shows some of the physicochemical attributes of tomatoes var. Charleston, which were characterized for being round fruits, with a light green before ripening and weight between 105 and 190 g. The acidity values obtained in the present work were lower than those obtained in other varieties of tomatoes in the same stage of ripeness [8]. Similar behavior was observed with the moisture content but not with pH and soluble solids content. Moreover, other authors [21, 22] reported, for tomatoes var. Charleston, similar values of soluble solids content and acidity to those found in this study.

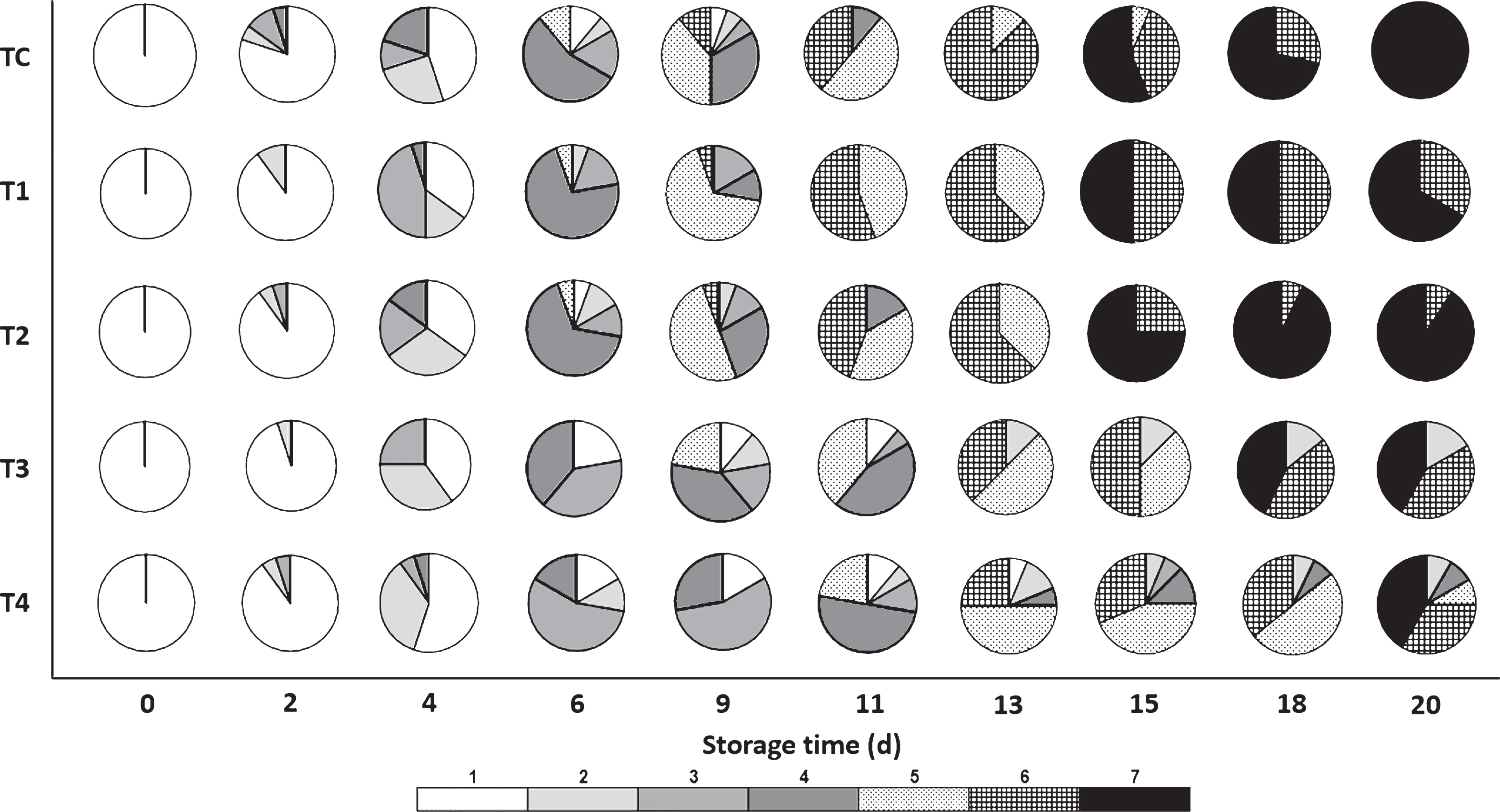

3.2Classification according to ripening stages

If it is considered that var. Charleston is a short-life variety of tomatoes and that its marketing cycle is about 10 and 12 days at 6–8°C [2], all the evaluated treatments retarded the ripening degree (Fig. 1) compared to control. T3 and T4 were the most effective treatments. In both of them the tomatoes presented a lower ripening degree compared with T1 and T2, which presented higher percentages of tomatoes in more advanced ripening stages (stages 6 and 7). Even after 21 days of storage, exclusively in T3 and T4 there were tomatoes in the second ripening stage, according with the graphic scale. Similar results have been informed in other works [8, 23] related with the application of chitosan coatings in tomatoes.

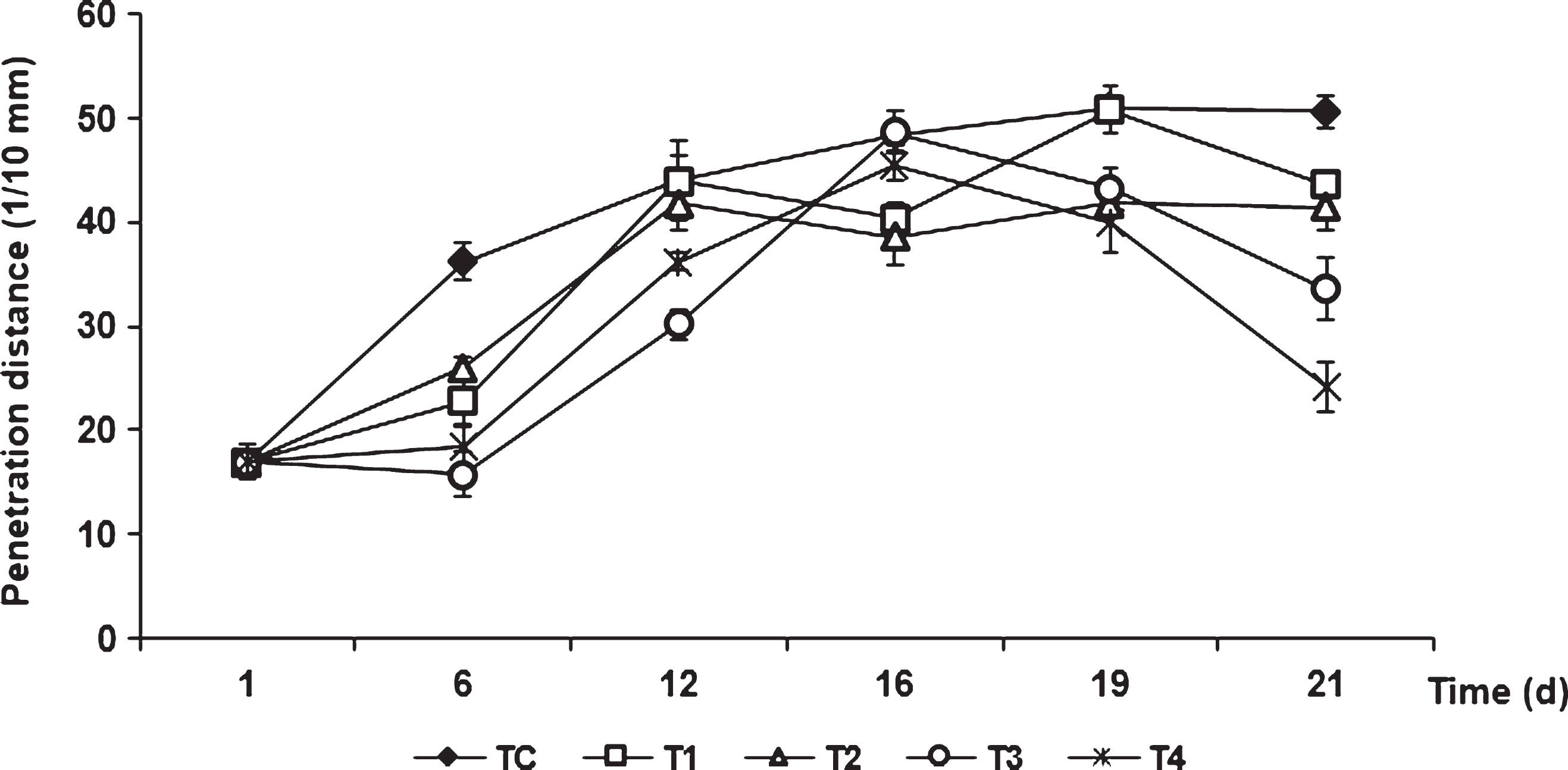

3.3Texture analysis

According to Fig. 2, tomatoes from the control batch (C) were less firm than coated tomatoes, which is in correspondence with the results reported by other works [8, 23], who used chitosan as a structural support of coatings. Treatments T3 and T4 showed lower penetration distance. At 12 days of storage, the tomatoes of these groups were the strongest fruits, maintaining this behavior up to 21 days. The time and type of coating influenced in the penetration distance, which increased significantly with time (p≤0.05).

3.4Variation of soluble solids content, pH and titrable acidity during storage

Table 3 shows that there was not a significant difference (p≤0.05) of soluble solids content among treatments during storage. The values of soluble solids varied between 4.2 and 5 °Brix, which coincides with the range reported (4.5 and 5.5°Brix) in other papers [24].

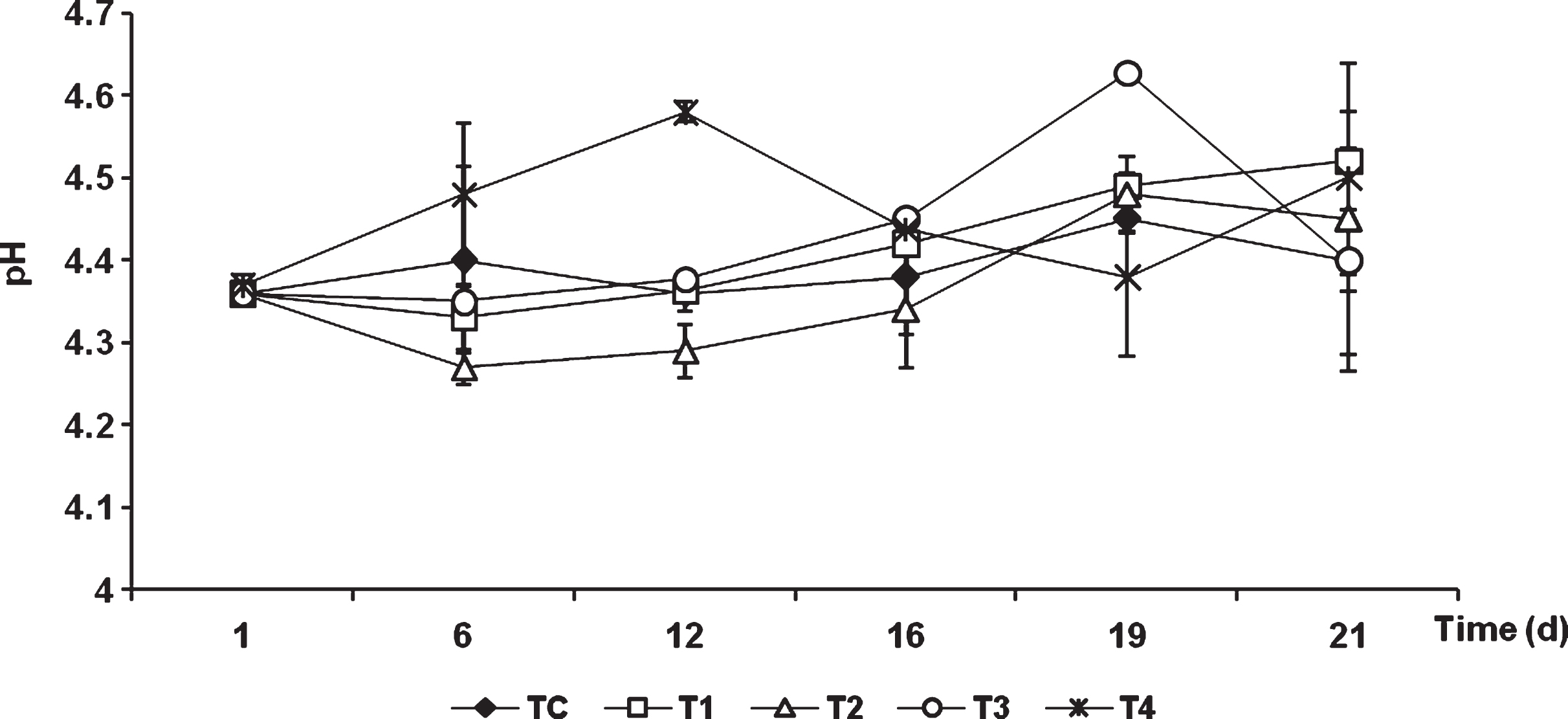

The pattern of changes in pH (Fig. 3) showed no marked variations during storage, except in a general way, the T4 and T3 treatments at 12 and 19 days, respectively.

The results from the multifactorial analysis indicate that time and treatments as well as the interaction between them, influenced the pH values. Other authors [8] reported for tomatoes cv. FA-180 treated with chitosan, pH values between 4 and 4.4, which are similar to those found in the present study, where values ranged between 4.2 and 4.6.

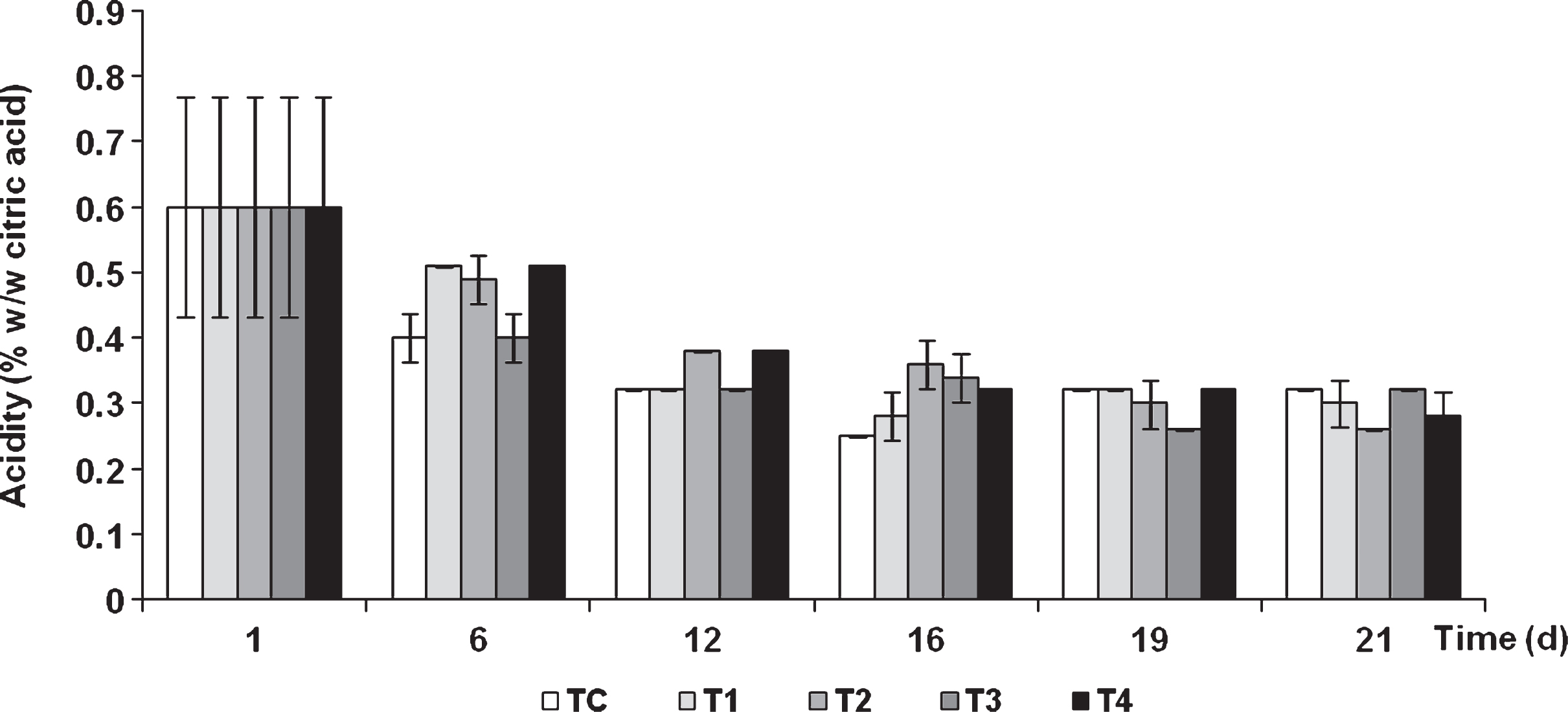

The titrable acidity (Fig. 4) decreased significantly (p≤0.05) with the time, but not between treatments. Different results were reported by other authors [8] who found differences between the titrable acidity values of the coated tomatoes and controls.

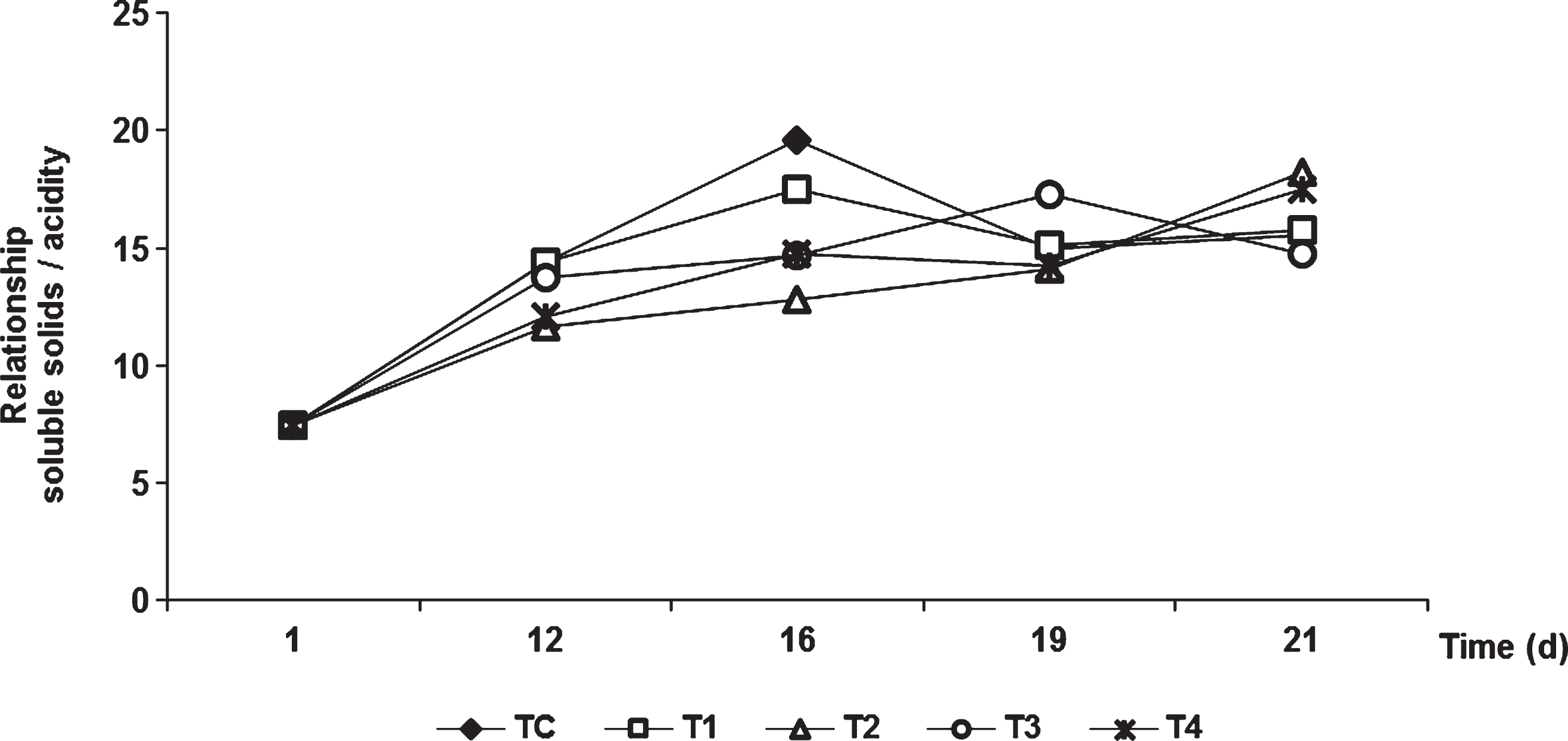

3.5Relationship of soluble solids/acidity during storage

The relationship soluble solids/acidity percentage (Fig. 5) shows an increase with the time. This relationship is considered as a ripening index for citrus fruits, however, is used as an indicator of taste for the tomato [25].

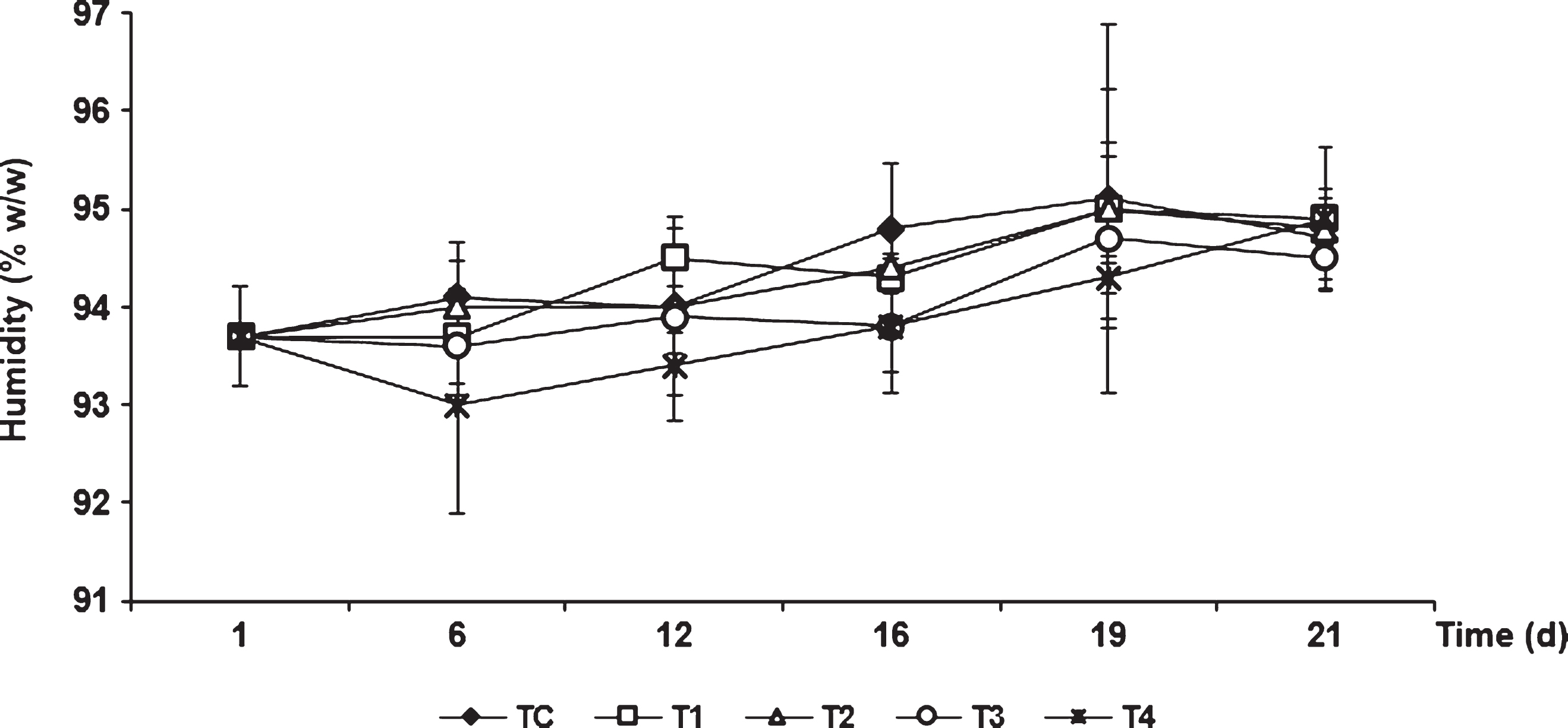

3.6Variation of moisture content and weight loss during storage

Several factors such as surface area/volume, product integrity, technological factors as relative humidity of the storage atmosphere and the use of coatings, can affect the water loss [8].

According to Fig. 6, the variation of moisture content was similar for all the treatments. The results indicate that storage time had a significant effect (p≤0.05) in the moisture percentage and do not the applied treatments.

The variation of weight loss (Table 4) showed an increase of this percentage during storage. The results indicate that the treatments and the storage time had influence (p≤0.05) in the weight loss of tomatoes, being higher in tomatoes of T3 and T4. These data are in correspondence with those reported by other work [8] in which uncoated tomatoes cv. FA-180 lost less weight than those coated with chitosan.

3.7Physiological decay

Table 5 shows that the highest percentages of wrinkled tomatoes (D3) by dehydration corresponded with tomatoes of the treatment T4 at the end of the storage.

4Discussion

4.1Characterization of tomato

The difference between the obtained values for the quality attributes and those reported, may be due to typical genotypic variation of the varieties under study, as well as agricultural conditions during pre and postharvest [25].

4.2Classification according to ripening stages

The ripening degree is an important factor to take into account during the harvest, because it will determine the treatment in the successive phases as well as the storage conditions to be applied in order to keep the product in good physiological and nutritional status. A phenomenon closely related to the ripening is the evolution of color. In the particular case of tomato, it suffers significant organoleptic changes during ripening that lead to decrease chlorophyll and increase lycopene, pigments that contribute substantially to the quality of the product [26].

The delay in the ripening observed with T3 and T4 treatments was a result of the action of the coatings with the highest percentages of chitosan in the formulation, which acted as barriers to oxygen and other volatile gases as ethylene, responsible for ripening [27].

4.3Texture analysis

One of the factors most important to the consumer is the firmness, which is closely related to the ripening evolution. This attribute is inversely related to the penetration distance, thus an increase in penetration distance is in correspondence with in a firmness decrease. Fruit texture is influenced by a number of structural and chemical factors which are related to biochemical constituents of cell organelles, water content and cell wall composition [28]. The fruit softening is associated with the loss of the assembled structures of the primary cell wall and middle lamella [29].

The results showed in Fig. 2, relative to firmness of tomatoes during storage, are in correspondence with the results obtained for ripening stages (Fig. 1). During ripening, a decrease in the firmness of the fruits it is normal as a consequence of the ethylene production, which increases the synthesis of polygalacturonase, enzyme responsible for softening [30].

4.4Variation of soluble solids, pH, and titrable acidity during storage

The total solids content and the soluble solids content are indexes that are correlated, although the content of soluble solids is normally used because it is easier to measure. Moreover, it is the index that most influences performance during processing of tomato.

According to other authors [31–33], the increasing of nutrients concentration in solution during the preparation of fertilizers, causes an increase in the electrical conductivity of soils, which is associated with the increase of total soluble solids in tomatoes. In this sense, the values of soluble solids found in this study could be due to cultural practices carried out in the greenhouse cultivation. Other authors [34] assert that the increase in soluble solids is the result of restricted flow of water to the fruit, due to the osmotic effect of the high electrical conductivity.

Referred to the pH variation (Fig. 3), the comportment that was observed in treatments T4 and T5 may be explained by the intrinsic variation in the composition of the evaluated experimental units, which depends on environmental factors and cultural practices.

The results of titrable acidity (Fig. 4) are generally in correspondence with the evolution of the pH during storage.

4.5Relationship of soluble solids/acidity during storage

The relationship soluble solids/acidity percentage observed in Fig. 5 was influenced mostly by acidity values, because the soluble solids did not show significant changes during storage. The values obtained for this indicator suggest a good taste of the analyzed tomatoes, since according to other authors [21], a low level of titratable acidity and high content of soluble solids determine a good taste in these fruits.

4.6Variation of moisture content and weight loss during storage

At the harvest time, the water level of plant products is very high, but when the interruption of their natural life cycle takes place, they are unable to take water from the plant and continues the water loss by transpiration. This water deficit during storage mainly affects the turgidity of fruit tissues, affecting the loss of this will affect several metabolic functions, but above all, changes in texture, leading to a loss of fresh product and affects the quality of its [35].

The results obtained respect to the moisture content (Fig. 6) could be due to hydrophilic nature of chitosan that affects his function as barrier against the water vapor [36].

The variation of the weight loss (Table 4) is a process associated with the ripening [23]. The results obtained in T3 and T4 treatments are in correspondence with other articles [36] that corroborate the increase of the water vapor permeability of chitosan-emulsified films, which is related with the fact that the applied coatings did not decrease the weight loss of tomatoes.

Although the coatings applied in this study did not play an efficient role against weight loss, when Table 4 is analyzed and it is considered a physiological weight loss of 10% as completion rate of the shelf life of tomato [38–40], it can be said that in any case the obtained losses did not compromise the quality of stored fruit.

4.7Physiological decay

From the point of view of quality, it is considered important the visual appearance of the tomatoes, which showed deterioration due to loss of water, resulting in a physiological decay. The result showed in the Table 5 is consistent with the existence of significant differences (p≤0.05) in weight loss among treatments (Table 4).

5Conclusions

Coatings from chitosan-olive oil emulsion delayed the ripening and maintained the firmness of tomatoes cv. Charleston with respect to uncoated fruits, contributing to extend their shelf life during storage at ambient conditions (27±1°C and 80% RH), although these coatings did not act as an effective barriers against the weight loss. Tomatoes coated with chitosan at 2% (w/v) with 2 and 4% (v/v) of olive oil presented the higher weight losses. The results of this study can be helpful for horticulturists and agro-food products distributors, as well as for the postharvest technologists.

Although some researches indicated the potentialities of emulsions as coating material in fruits and vegetables for improving its quality, the success of coating-forming emulsions for food products depends, primarily, on their effective wetting capacity, which affects the coating properties. Surface properties for designing a food coating process needs a priori knowledge of the surface tension of the coating material and surface of the food to be coated. Various studies highlighted the importance of surface properties of coatings in fruits and vegetables, however, there is not available reports describing the surface properties of coating-forming emulsions in relation with the product to be coated, which could be interesting in the development of coatings for this type of products.

References

1 | Díaz R, Casariego A, Rodríguez J, Martínez A, García MA (2010) Coberturas de quitosana como método de envasado activo en vegetales enteros y cortados Cienc Tecnol Aliment 20: 2 31 36 |

2 | García MA, Ventosa M, Díaz R, Falco S, Casariego A (2014) Effects of Aloe vera coating on postharvest quality of tomato Fruits 69: 2 117 126 |

3 | Gastélum-Barrios A, Bórquez-López RA, Rico-García E, Toledano-Ayala M, Soto-Zarazúa GM (2011) Tomato quality evaluation with image processing: A review Afr J Agric Res 6: 14 3333 3339 |

4 | Rodríguez MS, Ramos V, Pistonesi M, Del Blanco L, Agulló E (1998) Preservación de membrillos (Cydonia oblonga) con películas de quitosano InformaciónTecnológica 9: 3 129 134 |

5 | García MA (2008) Películas y cubiertas de quitosana en la conservación de vegetales Cienc Tecnol Alim 18: 1 71 76 |

6 | Sirinivasa PC, Ramesh MN, Kumar KR, Tharanathan RN (2004) Properties of chitosan films prepared under different drying conditions J Food Eng 63: 79 85 |

7 | Casariego A (2009) Desarrollo de películas y coberturas de quitosana de empleo potencial en alimentos Doctoral Thesis Pharmacy and Food Institute, University of Havana Cuba |

8 | García MA, Casariego A, Díaz R, Roblejo L (2014) Effect of edible chitosan/zeolite coating on tomatoes quality during refrigerated storage Emir J Food Agric 26: 3 238 246 |

9 | Shahidi F (2004) Nutracéuticos marinos. Aceites y grasas Tomo XIV 4: 57 656 660 |

10 | Mei Y, Zhao Y (2003) Barrier and mechanical properties of milk protein-based edible films containing nutraceuticals J Agric Food Chem 51: 1914 1918 |

11 | Chandra R, Rustgi R (1998) Biodegradable polymers Process Polym Sci 23: 1273 1335 |

12 | Sandford PChitosan: Commercial uses and potential applications (1989) Chitin and chitosan sources chemistry, biochemistry, physical properties and applications Skjak-Braek S, Anthonsen T, Sandford P Elsevier Appl Sci 58: 33 48 |

13 | Wang S, Hao H (2013) Effect of chitosan-based edible coating on antioxidants, antioxidant enzyme system, and postharvest fruit quality of strawberries (Fragaria x aranassa Duch) LWT 52: 71 79 |

14 | USDA. United States Standards for Grades of Fresh Tomatoes. U.S. [homepage on the Internet]. Dept. Agric./AMS. Washington DC. [updated 1991, cited 2007]. Available from: www.ams.usda.gov/standards/vegfm.htm |

15 | Vargas M, Albors A, Chiralt A, González-Martínez C (2006) Quality of cold-stored strawberries as affected by chitosan-oleic acid edible coatings Postharvest Biol Technol 41: 164 171 |

16 | Wills R, McGlasson B, Graham D, Joyce D (1998) 240 Introducción a la fisiología y manipulación poscosecha de frutas, hortalizas y plantas ornamentales 2nd Ed Zaragoza Acribia, Spain |

17 | NC-ISO 2173 Productos de frutas y vegetales. Determinación del contenido de sólidos solubles. Método refractométrico. Oficina Nacional de Normalización. Havana, Cuba; 2001. |

18 | NC-ISO 1842 Productos de frutas y vegetales Determinación del pH. Oficina Nacional de Normalización. Havana, Cuba; 2001. |

19 | NC-ISO 750 Productos de frutas y vegetales Determinación de la acidez valorable. Oficina Nacional de Normalización. Havana, Cuba; 2001. |

20 | NC-77-22-8 Conservas de frutas y vegetales Métodos de ensayo. Determinación de la humedad. Oficina Nacional de Normalización. Havana, Cuba; 1982. |

21 | Tando KS, Baldwin EA, Scott JW, Schewfelt RL (2003) Linking sensory descriptors to volatile and non-volatile components of fresh tomato flavor J Food Sci 68: 2366 2371 |

22 | Cruz E (2010) Mezclas de Vermicompost y Tezontle diseñadas mediante un programade optimización en SAS, para el cultivo de tomate bajo invernadero e hidroponía Doctoral thesis, Institución de Enseñanza e Investigación en Ciencias Agrícolas Edo. De México: Montecillo, Texcoco |

23 | Rodríguez JL (2004) Aplicación de una cobertura biodegradable de quitosana en la conservación de tomates Bachelor thesis Pharmacy and Food Institute, University of Havana |

24 | Diez JM (2001) Tipos varietales El cultivo del tomate Nuez F España: Madrid Mundi-Prensa 95 129 |

25 | Artés F, Artés-Hernéndez F (2004) Tratamientos postrecolección del tomate fresco. Tendencias e innovaciones Tomates. Producción y comercio, Ed. Hortic Namesny A Spain S.L. Reus |

26 | González RA (2004) Evolución de pigmentos en frutos de tomate de larga vidas sometidos a estrés térmico durante la poscosecha Master thesis Pontificia Universidad Católica de Chile |

27 | Pen LT, Jiang YM (2003) Effects of chitosan coating on shelf life and quality of fresh-cut Chinese water chestnut LWT 36: 3 359 364 |

28 | Sams CE (1999) Preharvest factors affecting postharvest texture Postharvest Biol. Technol 15: 249 254 |

29 | Jackman RL, Stanley DW (1995) Perspectives in the textural evaluation of plant foods Trends Food Sci Technol 6: 187 194 |

30 | Ramírez H, Encina-Rodríguez LI, Benavides-Mendoza A, Robledo-Torres V, Hernández-Dávila J, Alonso-Corona S (2004) Influencia de la temperatura sobre procesos fisiológicos en postcosecha de tomate Lycopersicon esculentum Mill Nueva Época 1: 3 31 37 |

31 | Wu M, Johann M, Buck S, Kubota C (2004) Effects of nutrient solution EC, plant microclimate and cultivars on fruit quality and yield of hydroponic tomatoes (Lycopersicon esculentum) Acta Hort 659: 541 549 |

32 | Claussen W, Brückner B, Krumbein A, Lenz F (2006) Long-term response of tomato plants to changing nutrient concentration in the root environment-the role of proline as an indicator of sensory fruit quality Plant Sci 171: 323 331 |

33 | Krauss S, Schnitzler WH, Grassman J, Woitke M (2006) The influence of different electrical conductivity values in a simplified recirculating soilless system on inner and outer fruit quality characteristics of tomato J Agric Food Chem 54: 441 448 |

34 | Wu M, Kubota C (2008) Effects of high electrical conductivity of nutrient solution and its application timing on lycopene, chlorophyll and sugar concentrations of hydroponic tomatoes during ripening Sci Hort 116: 122 129 |

35 | Gómez-Galindo F, Herppich W, Gekas V, Sjoholm I (2004) Factor affecting quality and postharvest properties of vegetables: Integration of relations and metabolism Crit Rev Food Sci Nutr 44: 139 154 |

36 | López-Mata MA, Ruiz-Cruz S, Navarro-Preciado C, Ornelas-Paz JJ, Estrada-Alvarado MI, Gassos-Ortega LE (2012) Effect of chitosan edible coatings in the microbial reduction and conservation of the quality of strawberries J Bio Sci Health 14: 1 33 43 |

37 | Trejo V, Aragón N, Miranda P (2001) Estimación de la permeabilidad al vapor de agua en películas a base de quitosán Rev Soc Quím Méx 45: 1 5 |

38 | Pal RK, Roy SK, Srivastava SS (1997) Storage performance of Kinnow mandarins in evaporative cool chamber and ambient conditions J. Food Sci. Technol 34: 3 200 203 |

39 | Acedo AL (1997) Storage life of vegetables in simple evaporative coolers Tropical Sci 37: 169 175 |

40 | Getinet H, Seyoum T (2008) The effect of cultivar, maturity stage and storage environment on quality of tomatoes J. Food Eng 87: 4 467 478 |

Figures and Tables

Fig.1

Ripening stage distribution of tomatoes during storage of uncoated fruits (TC) and fruits coated with chitosan and olive oil at different concentrations. In the color visual scale, the extremes, 1 and 7, represent green and red colors, respectively.

Fig.2

Changes in the firmness of tomatoes during storage of uncoated fruits (TC) and fruits coated with chitosan and olive oil at different concentrations. Vertical bars indicate standard deviation (n = 3).

Fig.3

Changes in pH of tomatoes during storage of uncoated fruits (TC) and fruits coated with chitosan and olive oil at different concentrations. Vertical bars indicate standard deviation (n = 3).

Fig.4

Changes in acidity of tomatoes during storage of uncoated fruits (TC) and fruits coated with chitosan and olive oil at different concentrations. Vertical bars indicate standard deviation (n = 3).

Fig.5

Changes in the relationship of soluble solids and acidity content of tomatoes during storage of uncoated fruits (TC) and fruits coated with chitosan and olive oil at different concentrations. Vertical bars indicate standard deviation (n = 3).

Fig.6

Changes in humidity content of tomatoes during storage of uncoated fruits (TC) and fruits coated with chitosan and olive oil at different concentrations. Vertical bars indicate standard deviation (n = 3).

Table 1

Preparation of chitosan coating-forming emulsions according the treatments

| Treatments | Chitosan (% w/v) | Lactic acid (% v/v) | Olive oil (% v/v) |

| T1 | 1 | 1 | 2 |

| T2 | 1 | 1 | 4 |

| T3 | 2 | 1 | 2 |

| T4 | 2 | 1 | 4 |

Table 2

Characterization of tomatoes in breaker stage (n = 5)

| Parameters | Media (Standard deviation) |

| Weight (g) | 148 (18) |

| Soluble solids (°Brix) | 4.5 (0.4) |

| pH | 4.36 (0.01) |

| Humidity content (% w/w) | 93.7 (0.5) |

| Penetration distance (1/10 mm) | 17 (1) |

| Acidity (% w/w of citric acid) | 0.6 (0.1) |

Table 3

Variation of soluble solids during storage of uncoated fruits (TC) and fruits coated with chitosan and olive oil at different concentrations

| Time (d) | Soluble solids (°Brix) | ||||

| TC | T1 | T2 | T3 | T4 | |

| 1 | 4.47 (0.41) bcde | 4.47 (0.41) bcde | 4.47 (0.41) bcde | 4.47 (0.41) bcde | 4.47 (0.41) bcde |

| 6 | 4.27 (0.28) def | 4.23 (0.11) def | 4.10 (0.17) efg | 3.77 (0.46) g | 3.87 (0.05) fg |

| 12 | 4.60 (0.00) abcd | 4.60 (0.00) abcd | 4.43 (0.15) cde | 4.40 (0.00) cde | 4.60 (0.20) abcd |

| 16 | 4.90 (0.00) ab | 4.90 (0.10) ab | 4.60 (0.20) abcd | 5.00 (0.10) a | 4.73 (0.23) abc |

| 19 | 4.80 (0.10) abc | 4.83 (0.23) abc | 4.23 (0.11) def | 4.50 (0.17) bcde | 4.57 (0.15) abcd |

| 21 | 4.97 (0.05) a | 4.73 (0.11) abc | 4.73 (0.11) abc | 4.73 (0.11) abc | 4.90 (0.10) ab |

Mean (Standard deviation); n = 3. Different letters indicate significant differences (p≤0.05) by Duncan’s multiple range test.

Table 4

Variation of the weight losses during storage of uncoated fruits (TC) and fruits coated with chitosan and olive oil at different concentrations

| Time (d) | Weight loss (% w/w) | ||||

| TC | T1 | T2 | T3 | T4 | |

| 3 | 0.59 (0.09) f | 0.58 (0.13) f | 0.55 (0.05) f | 0.86 (0.29) f | 0.82 (0.24) f |

| 5 | 1.22 (0.15) f | 1.18 (0.25) f | 1.11 (0.10) f | 1.83 (0.62) e | 1.76 (0.53) e |

| 7 | 1.88 (0.21) e | 1.79 (0.37) e | 1.68 (0.15) ef | 2.77 (0.89) de | 2.66 (0.79) de |

| 10 | 2.66 (0.28) de | 2.54 (0.50) de | 2.36 (0.23) de | 3.85 (1.18) cd | 3.74 (1.09) cd |

| 12 | 3.16 (0.33) cd | 3.06 (0.60) d | 2.83 (0.29) de | 4.54 (1.38) bc | 4.45 (1.26) bc |

| 14 | 3.69 (0.37) cd | 3.68 (0.73) cd | 3.44 (0.36) cd | 5.32 (1.59) bc | 5.23 (1.46) bc |

| 16 | 4.29 (0.43) c | 4.38 (0.88) c | 4.10 (0.46) cd | 6.15 (1.81) b | 6.08 (1.65) b |

| 19 | 5.17 (0.50) bc | 5.56 (1.22) b | 5.22 (0.68) bc | 7.48 (2.15) a | 7.47 (1.94) a |

| 21 | 5.70 (0.55) b | 6.46 (1.47) b | 5.85 (0.55) b | 8.39 (2.38) a | 8.45 (2.17) a |

Mean (Standard deviation); n = 8. Different letters indicate significant differences (p≤0.05) by Duncan’s multiple range test.

Table 5

Dehydration of fruits at the end of storage (%) of uncoated fruits (TC) and fruits coated with chitosan and olive oil at different concentrations

| Treatments | Time (d) | Dehydrated surface | ||

| D1 | D2 | D3 | ||

| TC | 16 | 18.75 | 0.0 | 6.25 |

| 19 | 0.0 | 0.0 | 7.14 | |

| 21 | 41.67 | 25.0 | 0.0 | |

| T1 | 16 | 37.5 | 0.0 | 0.0 |

| 19 | 7.14 | 14.28 | 21.43 | |

| 21 | 16.67 | 50.0 | 8.33 | |

| T2 | 16 | 37.5 | 0.0 | 6.25 |

| 19 | 14.28 | 14.28 | 0.0 | |

| 21 | 63.64 | 36.36 | 0.0 | |

| T3 | 16 | 31.25 | 25.0 | 6.25 |

| 19 | 21.43 | 7.14 | 28.57 | |

| 21 | 41.67 | 33.33 | 25.0 | |

| T4 | 16 | 25.0 | 37.5 | 6.25 |

| 19 | 7.14 | 28.57 | 21.43 | |

| 21 | 8.33 | 16.67 | 50.0 | |