Using IoT and AI to replenish household food supplies: A systematic review

Abstract

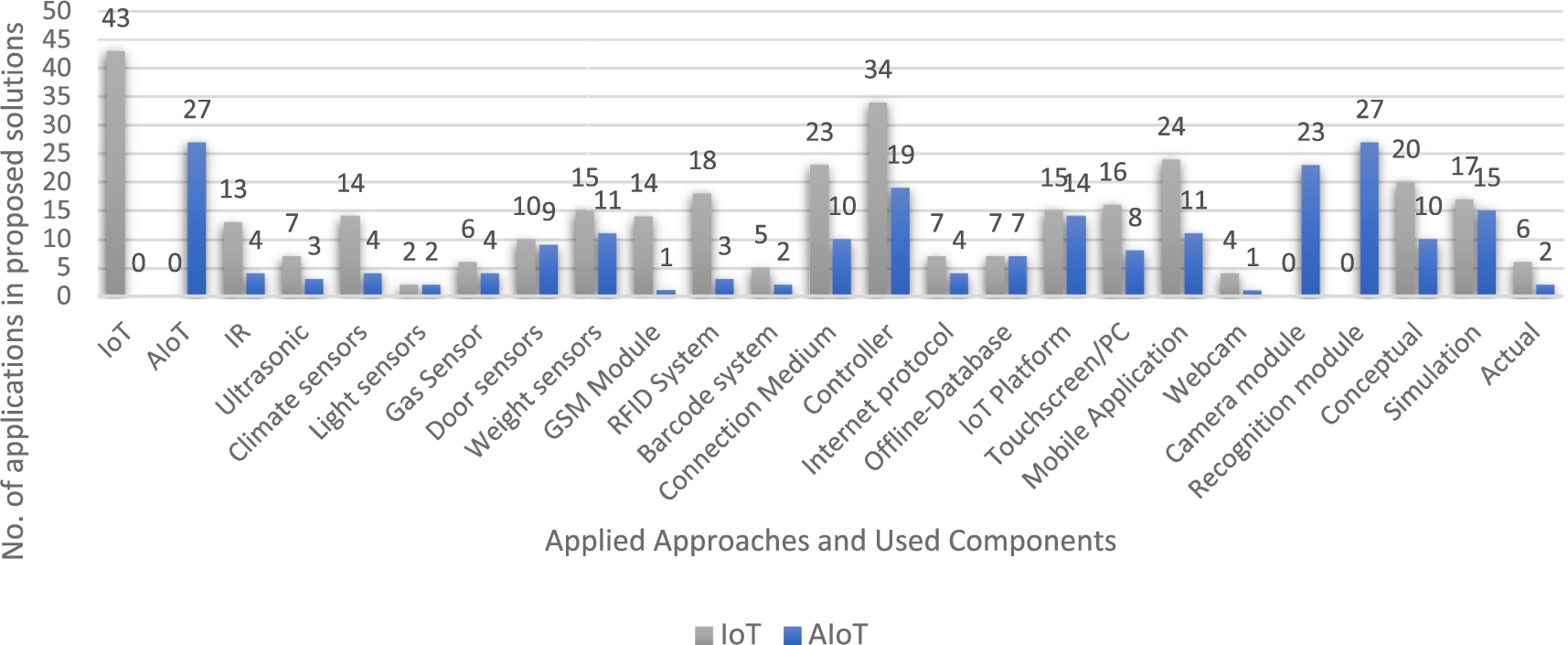

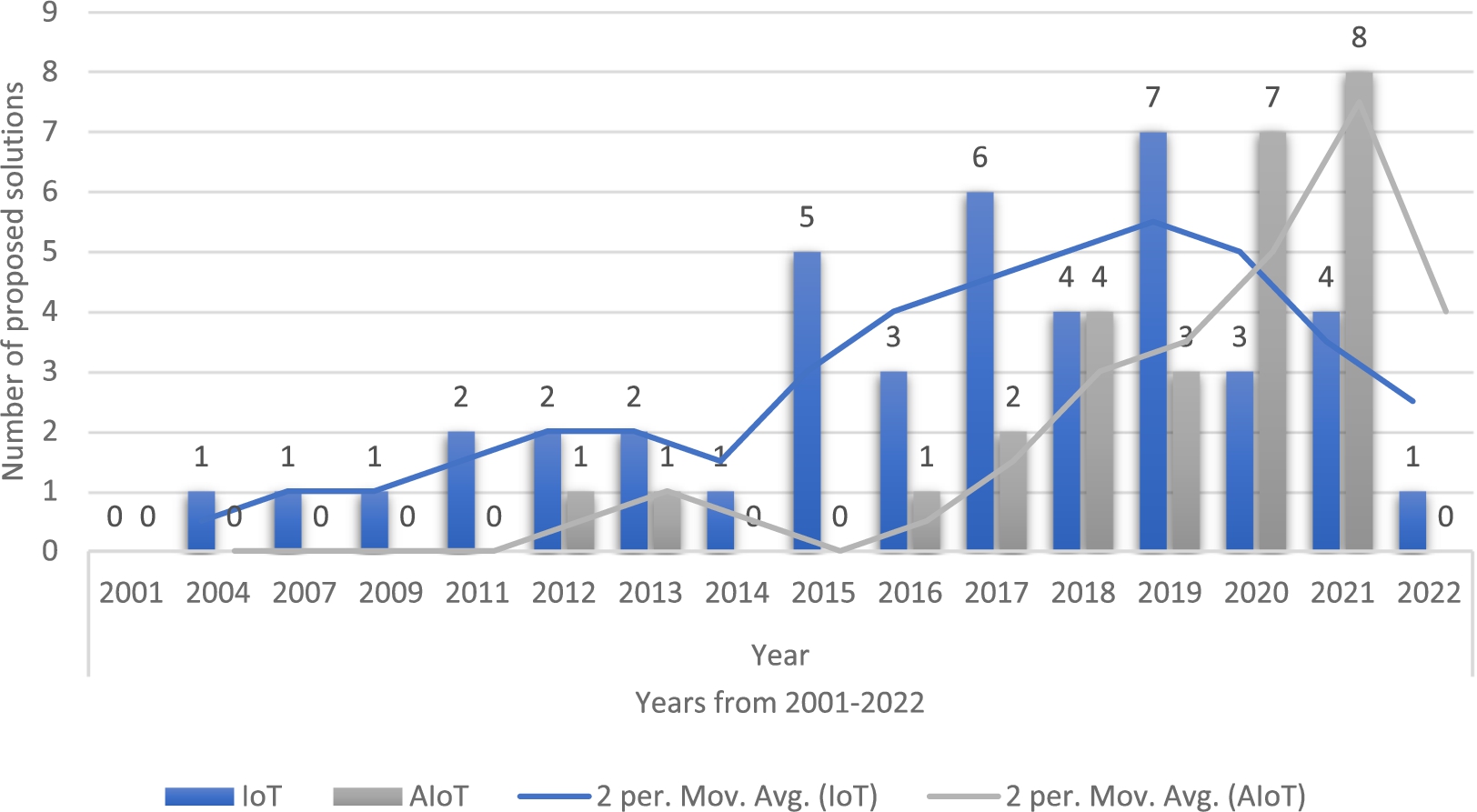

Food wastage because of the lack or incompletion of a household replenishment system is an essential topic to be addressed. An appropriate utilization of Internet of Things (IoT) and Artificial Intelligence (AI) technologies with particular components is needed to design a smart household replenishment system to reduce food wastage. Therefore, this systematic review is dedicated to survey papers utilizing IoT and AI tools for perishable items storage compartments, as they are always full of items that need to be monitored. This study was conducted by following the PRISMA search strategy. It examined 70 papers in chronological order starting from 2000 when LG Electronics invented the first smart refrigerator, and research on technology involvement in food storage compartments increased. This comprehensive research aims to point out the approaches, contributions, used components and limitations of the reviewed papers to develop a unified framework for a household replenishment system. The analysis resulted in 43 approaches using IoT technology, 27 using AI, and recently the use of AIoT has been trending in the past two years. This systematic review provides future directions for researchers acquired from the limitations of the reviewed papers to enhance the household replenishment system by developing and adding required features in smart food storage compartments. Further investigation into smart home appliances would lead to extensive approaches like smart shops, industries, and eventually smart cities.

1.Introduction

The waste of food is an essential issue to consider. There are many reasons for the waste. Without an organized shopping list, consumers purchase food based on imperfect memories of what remains at home and advanced marketing techniques used by supermarkets and other vendors. Additionally, severe weather conditions (or a pandemic in some cases) that require home isolation may make people unintentionally buy more than needed. People may forget their uneaten food, be unaware of expiration dates, store leftover food for too long, and food not well organized inside the refrigerator—losing food has many consequences. As part of home appliances, this paper intended to focus on refrigerators in particular as they always have perishable items that require monitoring. In contrast, other home appliances, such as washers and dryers, are occasionally used.

Inside the refrigerator, wasted food will unnecessarily consume space and electricity; the spoiled food means the water, labor, and other resources needed to produce it have been wasted [6,20,34,41,52,61]. A specialized agency of the United Nations called the Food and Agriculture Organization (FAO) studied food that ends up being wasted worldwide. The FAO study shows that one-third of the total amount of food worldwide is thrown away or lost, and consumers cause 40% of the waste [20,94]. The study was based on related kitchen appliances and the storage used to store food [20]. Adding features that track stored food items, monitor consumption and remaining food levels, will reveal a pattern of household behavior and consumption. The pattern will form the household replenishment system that will provide a shopping list to guide the household and stores. The historical information regarding the consumption rate of each perishable item will be gathered and recorded by the implanted sensors in the storage compartment. Then, it will be analyzed accordingly to form the pattern and predict the upcoming purchase along with the expected quantity [53,87].

Artificial Intelligence technology’s original seeds were planted in 1950 by Alan Turing [85]. Mr. Turing, proposed his idea in his book “Computing Machinery and Intelligence,” wherein he suggested people be concerned about the question “Can machines think?” [85]. From the proposed question by Mr. Turing, the basic idea of AI can be understood. It allows computers and machines to process data to be useful information using AI tools and techniques such as text mining, data mining, machine learning, image recognition, image processing, voice recognition, natural language processing, and other tools that allow machines to think, make and help decision-making processes like humans [34]. For example, Shweta in 2017 presented a solution for the smart refrigerator by using Artificial Intelligence technology [81]. The presented solution uses a machine-learning approach called the Aging algorithm. It includes a database to record the data processed by a microcontroller using the algorithm. The database is pre-loaded with images of different types of vegetables to train the data. The data was trained to detect the texture, shape, and other features of the captured images. It allows the system to compare the captured images with the loaded images. The comparison takes place to make a proper decision on the vegetable’s age. The system aims to monitor only vegetables. Thus, a camera is placed inside the refrigerator where the vegetables are located. The camera captures images and is connected to the microcontroller, where the images get analyzed for their age. After the analysis, the images will be sent to a microprocessor that converts and transmits the received information into signals. The signals will be received in the form of voice. Then, an attached voice indicator notifies the household about the vegetable status [81].

Nagarajua et al. [59] proposed a conceptual idea of using artificial intelligence in smart refrigerators to eliminate the wastage of food. This paper does not include specific components to be used; it was kept for the implementer to decide. The proposed solution has two approaches. One approach is using image recognition, referred to as predictive vision. Image recognition is an approach that could be applied by one of the AI tools called deep-neural networking. The authors suggested using the conventional neural network for vast data in this paper. The captured images will be processed, and the system will make the decision based on a comparison with pre-loaded identified images in a database and trained data. The second approach is using Natural Language Processing (NLP), which allows the household to communicate with the smart refrigerator by speaking out loud whenever they place items or take out items into or from the refrigerator; quantities of items can also be mentioned in the refrigerator. NLP will recognize the spoken information by the household and record it in a database. The database will be updated every time the household gives any voice command [59].

Gull et al. [27] proposed a conceptual idea for a system to enable the household to monitor food items stored in a smart refrigerator using Artificial Intelligence of Things (AIoT) via a personal computer. A novel idea of embedding the AI. Using decision tree advanced ID3 model, a machine learning algorithm, and an eNose system with different gas sensors. The gas sensors are used to identify food items, meat, rice, fruits, and vegetables from the emitted gases. Then, the captured data is sent to a trained database to label the food items accordingly [27]. Therefore, the camera module, eNose system, voice recognition, and Natural Language Processing technologies could mimic human action. The obtained data could be recorded and processed to train prediction models. Upon verification and validation of the developed models. The models would help to make proper decisions in predicting the suggested shopping lists and provide the desired output.

The state-of-the-art Internet of Things (IoT) technology made it easier to connect things (objects and electronic devices) to the Internet. IoT technology allows objects to communicate, exchange, and store information via communication channels, databases, and internet protocols that make up an IoT platform. The IoT is driven by AI technology. The IoT started in 1982 at the University of Carnegie Mellon. Computer science students modified a Coke machine so it would inform a computer network about the inventory status and drink temperature. The IoT revolution began in earnest in the early 1990s [21,40,84]. Just as the Carneige-Mellon students found Coke machine data useful, recent technological developments, as shown in this literature review, will bring accurate, timely information to consumers to automate their household replenishment systems. Information can be obtained by involving the new technology in home appliances. A patent titled “Household consumable item automatic replenishment system including intelligent refrigerator” granted to Sone in 2001 demonstrated an automated household replenishment system. It included various components that are interconnected and connected to the Internet to monitor stored items’ status. A detailed diagrams and illustrations were provided to illustrate the workflow of the proposed system [83]. Thus, it is essential for an easier lifestyle to maintain household demands along with proper management of supplies in a smart structure. The potential of IoT would lead to smart homes, markets, industries, and eventually smart cities [3].

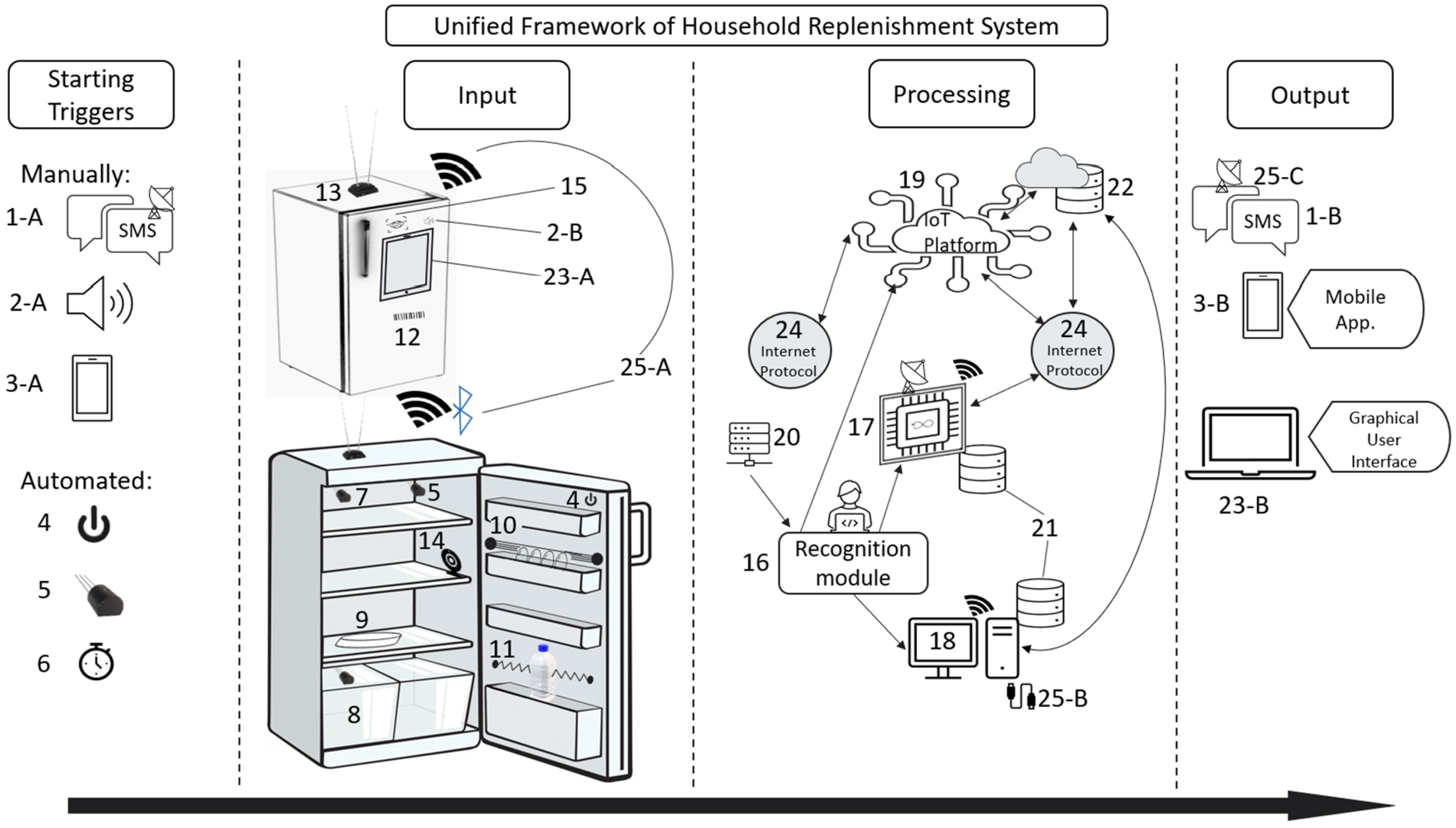

Realizing that information flow can arise after things have been identified and devices are connected in the same network, called Information integration, leads to thinking about making that possible. The literature found that exchanging data can be done in a system and stored in a shared database such as Google Firebase or an offline database. The data can be retrieved as input from sensors, RFID systems, camera modules, and barcode systems in many ways. A controller such as the Arduino UNO dashboard device can be configured to retrieve data from different sources, process them, and send them to a mobile application or a central database as an output [9], as shown in Fig. 1. The database is accessible by authorized people via the Internet. The information stored in this database can be viewed, managed, modified, and updated for several reasons. From the user’s perspective, the information could be about the flow of the stored items at home, allowing the households to make proper decisions about what to purchase next, know what items are about to expire, and control the surrounding climate to ensure freshness. Furthermore, if stores and suppliers are allowed to interact with that database, they can analyze the habits of each household, improve products, set proper marketing plans, form a pattern of subsequent purchases, and ensure the product availability [88].

Fig. 1.

Data flow of household replenishment system.

Most current devices can be identified and connected to the internet wirelessly via WiFi or Bluetooth connections or wired via Ethernet for exchanging information and other purposes. Appliances such as regular refrigerators or storage cabinets require specific AI or IoT components to allow them to be converted into smart storage compartments of perishable items.

This paper will focus on AI and IoT components and information integration methods used by the reviewed papers that enhance the household replenishment system. Therefore, this paper analyzes relevant research about how AI and IoT technologies can create a unified framework that includes all used components to eliminate food waste and enhance the Household Replenishment System and provide future directions. The presented possible combination of all used components could be used as guidance for developers and future directions for researchers.

The remainder of this systematic review is organized as follows; section two is the research methodology, section three is the Household Replenishment Systems Analysis, section four is the findings and discussions, and the fifth section is the conclusion and future directions.

2.Research methodology

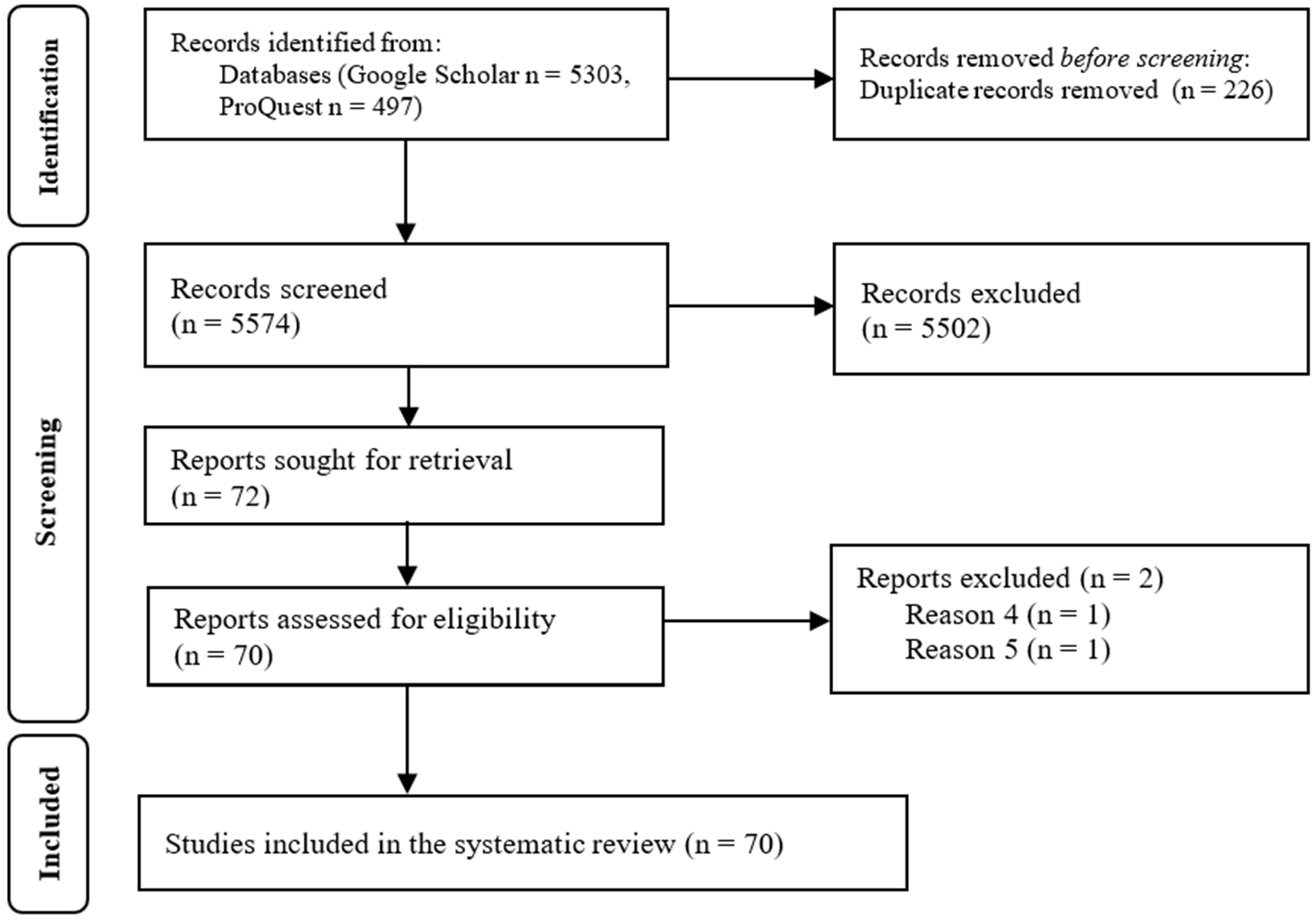

The comprehensive research has followed the PRISMA guidelines, as shown in Fig. 2, which are helpful for researchers creating and arranging systematic reviews [61].

Fig. 2.

Search strategy following PRISMA flow diagram 2020.

Several factors cause the slow movement of research and implementation of the new technologies needed to convert storage compartments into smart, home storage compartments for perishable items. Among them are the cost of system configuration, manufacturing, and research and security issues [61].

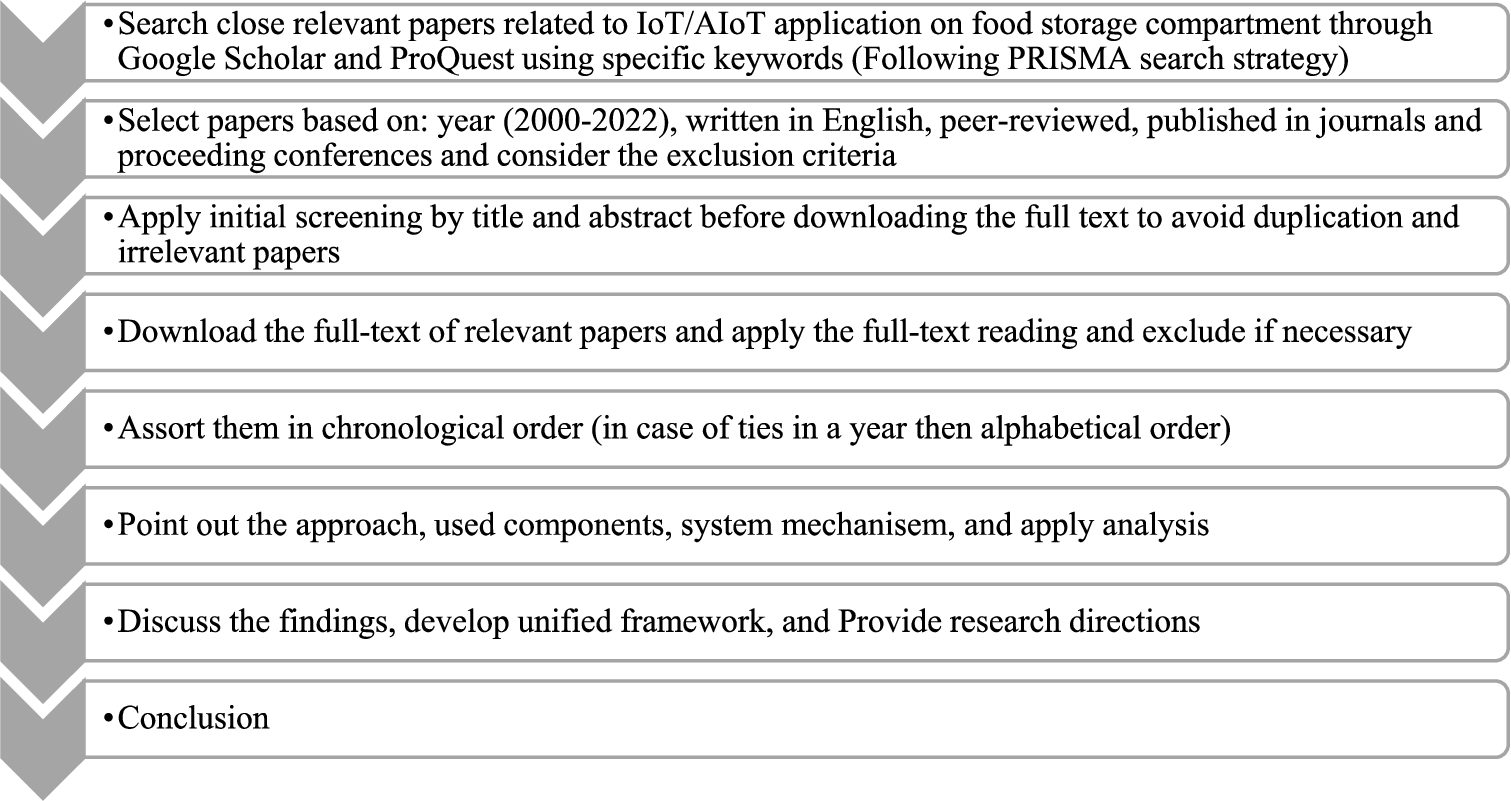

This systematic review surveys the relevant work on an application of IoT, Artificial Intelligence of Things (AIoT) technologies on perishable items storage compartments, the household interaction, and a detailed description of components, 2) point out the advantages and limitations of the concept, 3) find the frequency of the components appear in the research, 4) and perform data mining technique that built a decision tree for a continuous variable decision on the reviewed papers, and 5) offers a unified framework to developing a system that can include all necessary components. Also, future research directions to enhance the household replenishment system to reduce food wastage will be provided, as shown in Fig. 3.

Fig. 3.

Summary of the systematic review methodology.

This systematic review focuses on papers published from 2000 when LG Electronics invented R-S73CT the first smart refrigerator, and research on technology involvement in refrigerators began to increase [23,91]. Combination of keywords were used for the search, as follows: “Smart refrigerator”, “Smart refrigerator AND “internet of things”, “Smart refrigerator” AND “artificial intelligence”, “Smart Fridge”, “Grocery Ordering Systems”, “Fridge” AND “IoT” AND “AI” AND “Smart refrigerator”, “smart food storage”, “Intelligent Refrigerator”, “Intelligent Refrigerator” AND “artificial intelligence”, “Intelligent Refrigerator” AND “internet of things”. The search conducted in this paper uses ProQuest and Google Scholar databases. Only papers written in English and published in journals and conferences are selected for this paper. Publications were excluded if they had or were: 1) access restrictions for the entire paper, 2) papers for class projects, 3) proposed systems that applied IoT or AI on other than home food storage compartments, 4) relevant but the mechanism of household interaction was missing, and 5) newspapers, wire feeds, blogs, podcasts, websites, patents, dissertations and theses, books, and magazines are excluded. Table 1 shows a summary of the search results using the keywords and search engines.

Table 1

Summary of initial search results on both databases

| Used keywords | Number of results | Total | |

| ProQuest | Google scholar | ||

| “SMART refrigerator” | 283 | 1860 | 2143 |

| “Smart refrigerator AND “internet of things” | 0 | 131 | 131 |

| “Smart refrigerator” AND “artificial intelligence” | 86 | 647 | 733 |

| “SMART Fridge” | 96 | 1790 | 1886 |

| “Grocery Ordering Systems” | 2 | 18 | 20 |

| “Fridge” AND “IoT” AND “AI” AND “SMART refrigerator” | 5 | 94 | 99 |

| “smart food storage” | 0 | 26 | 26 |

| “INTELLIGENT REFRIGERATOR” | 13 | 447 | 460 |

| “INTELLIGENT REFRIGERATOR” AND “artificial intelligence” | 4 | 135 | 139 |

| “INTELLIGENT REFRIGERATOR” AND “internet of things” | 8 | 155 | 163 |

| Total | 497 | 5303 | 5800 |

The initial search resulted in 5800 possible papers to review, as shown in Fig. 2. Before the initial screening 226 duplicated results were removed. From the initial screening of the titles and abstracts of each result and applying the exclusion criteria, 72 papers remained in this systematic review. There were 42 conference papers and 28 published papers. Two papers were excluded after the full-text reading for reasons number 4 and 5.

Here are some examples of excluded papers after the screening of the title and the abstract with exclusion explanations:

A paper titled “Design of High-Efficiency Refrigerator Test System for Industrial Internet of Things” by Xian et al. [90] was excluded as it focuses on reducing the refrigerator’s power consumption.

A paper titled “A Taxonomy and Survey of IoT Cloud Applications” by Pflanzner et al. [68] It is about the application of IoT in general. It talks about the smart home appliance and the smart refrigerator as an example, stating the product of Samsung and its features. No details were given, and no solution was proposed.

A paper titled “Application of Affordance Factors for User-Centered Smart Homes: A Case Study Approach” by Younjoo et al. [15] is a case study about a smart home’s central interface that helps the user to view and manage home appliances, the smart refrigerator was one of the examples, and no details were given to support this systematic review.

A paper titled “Older Adult Segmentation According to Residentially-Based Lifestyles and Analysis of Their Needs for Smart Home Functions” by Jiyeon et al. [92] is about old people’s lifestyles and how vital smart homes are to them. Also, it brought the smart refrigerator as an example of what it could have as features briefly.

A paper titled “Monitoring in IOT enabled devices” by Gupta. [29] It talks about letting the smart refrigerator adjust the temperature itself based on the weather to reduce power consumption. It has nothing related to tracking food items inside the storage compartment.

A paper titled “Intrusion Detection In Internet Of Things (IOT)” by Anthony et al. [64] It talks about the security of IoT and provides a block diagram for how smart refrigerators are being connected through Bluetooth to a smartphone and showed it as an example with a weighing sensor. However, it is still about how hackers can easily interrupt it.

A paper titled “Safety of Food and Food Warehouse Using VIBHISHAN” by Khan et al. [43] talks about food safety and gives some ideas and tools to monitor it inside warehouses. There was no module or test implemented or even conceptual solution to support inclusion.

A paper titled “Multi-Class Fruit Classification Using Efficient Object Detection and Recognition Techniques” by Khan and Debnath [42] This paper is good as it helps in the fruit recognition method using AI. But it is being excluded as its focus is only on fruit recognition and removing the noise of the pictures to make a proper decision on the taken images. Therefore, it does not include the mechanism of tracking and reporting food items inside the refrigerator to the household, which is the focus of this work. Maybe later, this paper can be used to understand how to test the AI approach and get results of the developed unified framework.

Here are two examples of why papers were excluded after full-text reading:

The paper titled “Next Generation Smart Fridge System using IoT” by Bhatt et al. [10] is closely relevant to this review but was excluded. It was a class project.

The paper is titled “Inventory Management of the Refrigerator’s Produce Bins Using Classification Algorithms and Hand Analysis.” by Morris et al. [57] was excluded as it focuses only on hand detection and allowing the recognition model to clear the picture using a CNN classifier from the background and keeps the food items’ image for comparison. There is no mention of how the household interacted with the system. Maybe later, this paper can help to use the AI approach better and get robust results from the developed unified framework as an extension of this systematic review.

3.Household replenishment systems analysis

This section analyzes the selected papers based on the used approach and the implemented components. The 70 reviewed papers apply to the IoT technology or a combination of IoT and AI technologies, also referred to as Artificial Intelligence of Things (AIoT), and how those technologies can work with perishable item storage compartment systems.

Twenty-seven papers shed more light on the combination of AIoT components with perishable items storage compartments. Ten showed the results based on conceptual assumptions, 15 based on simulations, and 2 on the implementation of the system.

Forty-three papers drew the connection between IoT components and perishable item compartments. Twenty showed the solutions with conceptually assumed results, 17 of them were based on simulation, and six were on implementation of the system.

This section contains subsections that detail the IoT and AI components used in each reviewed paper. Each subsection will end with a table that summarizes the discussed matter. The component model and type will be written as mentioned in the reviewed papers. A checkmark (X) will be against the authors’ name if the type or model of the used component is included but not specified. Otherwise, it will be left blank or not listed in the subsections’ tables as it was not used.

This section ends with highlighted contributions, and limitations of and observations from each reviewed paper in Table 20 and Table 21, respectively. A complete table summarizes the subsections of the used components in Table 22. It forms the base for a data mining technique and a decision tree for a continuous variable decision. The frequency of used components among the reviewed papers is used to define the relationship between the used components and form them into categories. The continuous variable decision is used for the variables that depend on the outcome of each other, which applies to this paper. Therefore, this type of decision tree method is used, as shown in Table 23.

3.1.IR/ ultrasonic sensors

These sensors measure the liquid level inside items stored and the distance between them in the storage compartment. IR the infrared radiation sensors work by sending several light lines as signals across the compartment. Then, a measurement will be sent to the controller when a new or moved object interrupts the light to measure the distance or the remaining quantity level [89]. Ultrasonics are sound sensors that send sound signals and based on how the objects reflect, the distance will be measured [6]. A connected database will be updated with the feedback captured from these sensors, where the items’ status will be calculated accordingly [83]. Some authors used these sensors, as shown in Table 2.

Table 2

Articles in which the authors used IR/Ultrasonic sensors

| Article | Year | IR | Ultrasonic |

| Loh et al. [50] | 2004 | X | |

| Nayak et al. [62] | 2011 | X | |

| Lloret et al. [49] | 2012 | X | |

| Sandholm et al. [75] | 2014 | X | |

| Prapulla et al. [69] | 2015 | X | |

| Panchal et al. [67] | 2015 | X | X |

| Edward et al. [19] | 2017 | X | |

| Shama et al. [77] | 2017 | X | |

| Wu et al. [89] | 2017 | X-Distance (Sharp GP2YOA41SKOF) | |

| Anand et al. [6] | 2018 | HC-SR04T | |

| Hossain et al. [34] | 2018 | HC-SR04T | |

| Barfeh et al. [8] | 2019 | X | |

| Bayya [9] | 2019 | X | |

| Khan et al. [41] | 2019 | X | |

| Shariff et al. [78] | 2019 | X | X |

| Sharma et al. [79] | 2019 | X | |

| Mallikarjun et al. [52] | 2020 | X | HC-SR04T |

| Velasco et al. [86] | 2020 | X | |

| Das et al. [16] | 2021 | X | X |

| Jaipriya et al. [37] | 2021 | X | |

| Krishnamoorthy et al. [46] | 2021 | X | |

| Nejakar et al. [63] | 2022 | X |

3.2.Climate sensors

This component is different than the default built-in climate sensor. Temperature and humidity sensors are placed inside the storage compartment. These sensors give feedback to a connected device (controller or household mobile device) in the network or update the connected database with an up-to-date status of the storage climate. Some climate sensors can be programmed to control the climate inside the storage compartment from a distance. Several types of climate sensors are included in some of the reviewed papers, as shown in Table 3.

Table 3

Articles in which the authors used climate sensors

| Article | Year | Temperature/Humidity sensors |

| Lloret et al. [49] | 2012 | X |

| Gürüler [30] | 2015 | X-NTC negative temperature coefficient |

| Osisanwo et al. [65] | 2015 | X |

| Edward et al. [19] | 2017 | DS18B20 |

| Qiao et al. [70] | 2017 | DS18B20 |

| Shama et al. [77] | 2017 | LM35 |

| Nasir et al. [61] | 2018 | DHT11 |

| Zhongmin et al. [93] | 2018 | Temperature (DS18B20) /Humidity (DHT11) |

| Ahmed and Rajesh [4] | 2019 | Temperature (LM35) /Humidity (DH22) |

| Shariff et al. [78] | 2019 | X |

| Dong et al. [18] | 2020 | DHT11 |

| Chakilam et al. [13] | 2021 | DHT11 |

| Gupta et al. [28] | 2021 | Arduino Uno (Steinhart) |

| Jain et al. [36] | 2021 | DHT11 |

| Krishnamoorthy et al. [46] | 2021 | X |

| Nadar et al. [58] | 2021 | DHT11 |

| Sane et al. [76] | 2021 | Temperature (LM35) /Humidity (DH11) |

| Nejakar et al. [63] | 2022 | DHT11 |

3.3.Light sensors

A light sensor has different uses. Sometimes it can check the light inside the storage compartment. Once it senses light, it can trigger the connected equipment to function or send an alert that the refrigerator door is open [89]. A list of authors used this type of sensor in their systems, as shown in Table 4.

3.4.Gas sensors

A gas sensor is designed to sense and measure the gas generated by food items such as vegetables, fruits, and meat to identify the item type and predict spoilage. Several types of gas sensors were involved in some of the proposed systems, as shown in Table 5.

Table 5

Articles in which the authors used gas sensors

| Article | Year | Gas sensor |

| Lloret et al. [49] | 2012 | X |

| Anand et al. [6] | 2018 | ME3 |

| Nasir et al. [61] | 2018 | MQ3 |

| Zhongmin et al. [93] | 2018 | ZP07 |

| Ringe et al. [72] | 2019 | X |

| Shariff et al. [78] | 2019 | X |

| Chakilam et al. [13] | 2021 | MQ3 |

| Gull et al. [27] | 2021 | eNose System (Fruits/Vegetables: MQ3, Meat:MQ135) |

| Jain et al. [36] | 2021 | MQ3 |

| Nejakar et al. [63] | 2022 | MQ series |

3.5.Door open-close sensors

A door open-close sensor is a sensor that is used to trigger the connected equipment whenever the storage compartment’s door is opened and closed or remains open or alerts the household that the door is open. Some of the reviewed papers used several types of these sensors, as shown in Table 6.

Table 6

Articles in which the authors used door open-close sensors

| Article | Year | Door open-close sensor |

| Loh et al. [50] | 2004 | Switch |

| Nayak et al. [62] | 2011 | X |

| Kaldeli et al. [38] | 2013 | X |

| Lloret et al. [49] | 2012 | X |

| Sandholm et al. [75] | 2012 | LED |

| Son et al. [82] | 2014 | NFC |

| Kale et al. [39] | 2015 | X |

| Kwon et al. [47] | 2016 | Switch |

| Esmaeili [5] | 2017 | X |

| Hafidh et al. [32] | 2017 | X |

| Hossain et al. [34] | 2018 | X |

| Khan et al. [41] | 2019 | Camera |

| Sharma et al. [79] | 2019 | X |

| Mohammad et al. [56] | 2020 | X |

| Velasco et al. [86] | 2020 | X |

| Datey [17] | 2021 | X |

| Krishnamoorthy et al. [46] | 2021 | Servo motor |

| Lee et al. [48] | 2021 | X |

| Sharma et al. [80] | 2021 | X |

3.6.Weight sensors

Weight sensors can be placed or connected to the bottom of the storage shelves. Then these sensors give feedback to a connected device in the network or update the connected database with an up-to-date status of stored items’ weight as a quantity measurement. Some of the reviewed papers used several types of these sensors in their systems, as shown in Table 7.

Table 7

Articles in which the authors used weight sensors

| Article | Year | Weight sensors |

| Lloret et al. [49] | 2012 | X |

| Kale et al. [39] | 2015 | X |

| Prapulla et al. [69] | 2015 | X |

| Goeddel et al. [26] | 2017 | X |

| Hafidh et al. [32] | 2017 | X |

| Qiao et al. [70] | 2017 | X |

| Anand et al. [6] | 2018 | HX711 |

| Fujiwara et al. [24] | 2018 | KD-320 by TANITA and HX711-M |

| Hossain et al. [34] | 2018 | Flexi Forse A401 |

| Rezwan et al. [71] | 2018 | X |

| Zhongmin et al. [93] | 2018 | X |

| Ahmed and Rajesh [4] | 2019 | X |

| Bayya [9] | 2019 | X |

| Khan et al. [41] | 2019 | HX711 |

| Narayan et al. [60] | 2019 | HX711 |

| Ringe et al. [72] | 2019 | X |

| Kore et al. [45] | 2020 | HX711 |

| Mallikarjun et al. [52] | 2020 | HX711 |

| Velasco et al. [86] | 2020 | X |

| Datey [17] | 2021 | X |

| Gull et al. [27] | 2021 | HX711 |

| Gupta et al. [28] | 2021 | HX711 |

| Jain et al. [36] | 2021 | HX711 |

| Nadar et al. [58] | 2021 | HX711 |

| Sane et al. [76] | 2021 | X |

| Nejakar et al. [63] | 2022 | HX711 |

3.7.GSM module

The Global System for Mobile is a device that has a SIM port that enables the linked device to have telecommunication ability. It enables the storage compartment to send alerts based on the received data from the controller and sensors. Also, it allows the household to control the refrigerator by sending commands via SMS [50]. Some authors applied a GSM module, as shown in Table 8.

Table 8

Articles in which the authors used GSM module

| Article | Year | GSM module |

| Loh et al. [50] | 2004 | X |

| Nayak et al. [62] | 2011 | X |

| Rouillard [73] | 2012 | X |

| Kaldeli et al. [38] | 2013 | X |

| Gürüler [30] | 2015 | X |

| Kale et al. [39] | 2015 | X |

| Panchal et al. [67] | 2015 | X |

| Esmaeili [5] | 2017 | X |

| Hafidh et al. [32] | 2017 | X |

| Bayya [9] | 2019 | X |

| Shariff et al. [78] | 2019 | X |

| Das et al. [16] | 2020 | X |

| Datey [17] | 2021 | X |

| Jaipriya et al. [37] | 2021 | X |

| Krishnamoorthy et al. [46] | 2021 | X |

3.8.RFID system

The RFID system identifies objects from their identity tags. It consists of two parts the RFID tag and the RFID reader. The RFID tag is where the information about the thing is stored. It has two types, and each type has several models that read the associated tags [44]. One requires a long-life battery, and the information recorded on it can be modified and updated at any time, and it is called an RFID active tag. The other tag is called an RFID passive tag, and this type of tag does not require a battery as the tag will automatically activate once it becomes close to the RFID reader, and the information recorded in this tag cannot be changed. A tag will be attached to each object, and whenever that object becomes close to the RFID reader, it will be activated. The RFID reader will read the information, and then send it to a connected central database. Sometimes auto-scan can be set up to run an overall scan of the stored items to check their availability. The setup can be programmed to be periodically or triggered by another sensor [23]. Some authors applied the RFID system, as shown in Table 9.

Table 9

Articles in which the authors used RFID system

| Article | Year | RFID system |

| Hong et al. [33] | 2007 | x |

| Konidala et al. [44] | 2011 | X |

| Hou et al. [35] | 2013 | X |

| Kaldeli et al. [38] | 2013 | X |

| Son et al. [82] | 2014 | X |

| Osisanwo et al. [65] | 2015 | X |

| Calegari et al. [12] | 2016 | X |

| Floarea et al. [23] | 2016 | X |

| Hachani et al. [31] | 2016 | UHF |

| Esmaeili [5] | 2017 | X |

| Qiao et al. [70] | 2017 | X |

| Shama et al. [77] | 2017 | X |

| Anand et al. [6] | 2018 | X |

| Hossain et al. [34] | 2018 | X |

| Abdel-Basset et al. [2] | 2019 | X |

| Bayya [9] | 2019 | X |

| Ferrero et al. [22] | 2019 | X |

| Shariff et al. [78] | 2019 | X |

| Mohammad et al. [56] | 2020 | X |

| Jaipriya et al. [37] | 2021 | X |

| Nejakar et al. [63] | 2022 | X |

3.9.Barcode system

The barcode system is a technology that acts similar to the RFID system but it is a manual system. A barcode scanner is required to scan the barcode tag located on any barcoded item. The barcode tag consists of lines and numbers printed in a certain way representing information about an associated item. Then, a scanner reads the information about the scanned item and sends it to a connected database. The information carried by the barcode varies and may contain data such as an item’s type, quantity, and expiration date [33,50]. Some papers applied the barcode system, as shown in Table 10.

3.10.Connection medium

Most current devices have already been designed to be identified and connected to the internet wirelessly via a WiFi connection or wired via Ethernet and with each other via Bluetooth. Other appliances such as regular refrigerators or storage cabinets require specific IoT equipment to be identified. One of the reviewed papers used an Ethernet connection, a wired network that enables devices to communicate within a local area network and to the internet [30]. Some systems used different types of connections, as shown in Table 11.

Table 11

Articles in which the authors used connection medium

| Article | Year | Connection medium |

| Nayak et al. [62] | 2011 | Ethernet |

| Lloret et al. [49] | 2012 | X |

| Hou et al. [35] | 2013 | X |

| Gürüler [30] | 2015 | Ethernet |

| Kale et al. [39] | 2015 | X |

| Osisanwo et al. [65] | 2015 | X |

| Panchal et al. [67] | 2015 | X |

| Kwon et al. [47] | 2016 | X |

| Qiao et al. [70] | 2017 | X |

| Shama et al. [77] | 2017 | WiFi |

| Wu et al. [89] | 2017 | X |

| Anand et al. [6] | 2018 | X |

| Fujiwara et al. [24] | 2018 | X |

| Nasir et al. [61] | 2018 | X |

| Rezwan et al. [71] | 2018 | X |

| Zhongmin et al. [93] | 2018 | X |

| Abdel-Basset et al. [2] | 2019 | X |

| Ahmed and Rajesh [4] | 2019 | X |

| Barfeh et al. [8] | 2019 | WiFi |

| Bayya [9] | 2019 | X |

| Narayan et al. [60] | 2019 | X |

| Ringe et al. [72] | 2019 | X |

| Abd Elminam [1] | 2020 | Bluetooth |

| Avinash et al. [7] | 2020 | X |

| Kore et al. [45] | 2020 | X |

| Mohammad et al. [56] | 2020 | X |

| Velasco et al. [86] | 2020 | WiFi |

| Chakilam et al. [13] | 2021 | X |

| Datey [17] | 2021 | X |

| Gull et al. [27] | 2021 | X |

| Krishnamoorthy et al. [46] | 2021 | X |

| Nadaret al. [58] | 2021 | X |

| Sane et al. [76] | 2021 | X |

3.11.Controller

Controllers are used to send and receive information, store data, enable internet access for the connected equipment, and be configured to process the received data. Some of the reviewed papers used an IoT platform, tablets, or personal computers to act as the controller, but with larger data storage. Several types of controllers are installed in the systems conducted by the authors, as shown in Table 12.

Table 12

Articles in which the authors used controllers in their systems

| Article | Year | Controller |

| Loh et al. [50] | 2004 | X |

| Hong et al. [33] | 2007 | X as a grocery shopping agent |

| Luo et al. [51] | 2009 | TOUCHSCREEN |

| Konidala et al. [44] | 2011 | PC home server |

| Nayak et al. [62] | 2011 | X |

| Bostanci et al. [11] | 2013 | X |

| Kaldeli et al. [38] | 2013 | PC home server |

| Son et al. [82] | 2014 | PC |

| Gürüler [30] | 2015 | PIC187J60 |

| Kale et al. [39] | 2015 | X |

| Osisanwo et al. [65] | 2015 | X |

| Panchal et al. [67] | 2015 | Arduino Uno |

| Calegari et al. [12] | 2016 | Raspberry Pi |

| Floarea et al. [23] | 2016 | Arduino SoC model with Intel Edison processor |

| Kwon et al. [47] | 2016 | Arduino Uno-Raspberry Pi (Raspbian OS-Linux) |

| Esmaeili [5] | 2017 | Arduino Uno |

| Edward et al. [19] | 2017 | Arduino (NodeMCU) and Raspberry Pi3 |

| Hafidh et al. [32] | 2017 | Main board |

| Shama et al. [77] | 2017 | X |

| Shweta [81] | 2017 | X |

| Wu et al. [89] | 2017 | Raspberry Pi 2 BV1.1 |

| Anand et al. [6] | 2018 | Arduino ATMega2560 |

| Hossain et al. [34] | 2018 | Raspberry Pi |

| Nasir et al. [61] | 2018 | Arduino Uno WeMos D1R2 WiFi |

| Rezwan et al. [71] | 2018 | Arduino Mega and NodeMCU (ESP8266) |

| Zhongmin et al. [93] | 2018 | Aduino Arm Contex – M3 and STM32F103 ARM |

| Abdel-Basset et al. [2] | 2019 | X |

| Ahmed and Rajesh [4] | 2019 | Arduino Uno |

| Barfeh et al. [8] | 2019 | Raspberry Pi |

| Bayya [9] | 2019 | Arduino Uno |

| Khan et al. [41] | 2019 | Raspberry Pi for Fridge and Node MCU for sensors |

| Narayan et al. [60] | 2019 | Arduino Uno R3 AT Mega 328 (IDE Coding) and NodeMCU (ESP8266) |

| Ringe et al. [72] | 2019 | Raspberry Pi |

| Shariff et al. [78] | 2019 | Renesas GR Peach with (RFID and GPS) built-in: but not utilized |

| Sharma et al. [79] | 2019 | X |

| Abd Elminam et al. [1] | 2020 | Arduino Mega |

| Avinash et al. [7] | 2020 | X |

| Das et al. [16] | 2020 | Arduino Uno Atmega |

| Dong et al. [18] | 2020 | Arduino Leonardo |

Table 12

(Continued)

| Article | Year | Controller |

| Kore et al. [45] | 2020 | Raspberry Pi B3 |

| Mallikarjun et al. [52] | 2020 | Raspberry Pi B3 |

| Mohammad et al. [56] | 2020 | Arduino |

| Saha et al. [74] | 2020 | Raspberry Pi B3 – Python coding and OpenCV library for images |

| Chakilam et al. [13] | 2021 | NodeMCU-8266 and Raspberry Pi |

| Datey [17] | 2021 | X |

| Gull et al. [27] | 2021 | Arduino Uno IDE |

| Gupta et al. [28] | 2021 | Arduino Uno |

| Jain et al. [36] | 2021 | Arduino and Raspberry Pi 3B+ |

| Jaipriya et al. [37] | 2021 | X |

| Krishnamoorthy et al. [46] | 2021 | Raspberry Pi |

| Nadar et al. [58] | 2021 | NodeMcu |

| Sane et al. [76] | 2021 | Arduino Uno ATmega |

| Sharma et al. [80] | 2021 | Raspberry Pi |

| Nejakar et al. [63] | 2022 | Raspberry Pi |

3.12.Internet protocol

The Internet Protocol is a set of regulations controlling network communication with a given (IP address) that identifies machines connected to the internet or locally. An IP address will act as a unique identifier assigned to a smart refrigerator to allow the household to monitor and control that particular refrigerator [44]. Several types of internet protocols are applied in reviewed papers, as shown in Table 13.

Table 13

Articles in which the authors applied an Internet Protocol

| Article | Year | Internet protocol |

| Konidala et al. [44] | 2011 | HTTPS |

| Nayak et al. [62] | 2011 | X |

| Lloret et al. [49] | 2012 | X |

| Sandholm et al. [75] | 2014 | support HTTP POST, GET, JSON |

| Osisanwo et al. [65] | 2015 | X |

| Kwon et al. [47] | 2016 | HTTP |

| Hossain et al. [34] | 2018 | MQTT |

| Abdel-Basset et al. [2] | 2019 | X |

| Narayan et al. [60] | 2019 | MQTT |

| Ringe et al. [72] | 2019 | MQTT and COAP: to support images |

| Mallikarjun et al. [52] | 2020 | MQTT |

3.13.IoT platform

An IoT Platform allows objects to communicate, exchange, and store information via communication channels, databases, and internet protocols. According to Floarea et al. [23] there are four types of IoT platforms: 1) Machine-to-machine connectivity (M2M), which handles the communication between the IoT-connected components via a telecommunication network, but cannot process data; 2) Infrastructure as a Service (IaaS) acts as a backend server over the internet, allowing individuals to have a space with full access to control, store, and process data (platform is compatible with many operating systems); 3) Hardware-Specific software is exclusive software that operates devices; and 4) Consumer/Enterprise software extensions generally come as packages of multi-functional software programs and act as an IoT platform [3,23].

To operate an IoT platform, several features must be included [3,23]: 1) connectivity and normalization for the data flow assurance and accuracy, 2) device management where the connected devices are managed appropriately, 3) a scalable database that can accommodate vast amounts of data, 4) managing data from connected devices to take appropriate actions, 5) the ability to generate analytics reports based on individual preferences, 6) a dashboard to allow individuals to view meaningful information, 7) additional tools that allow testing, implementing, and modeling, and 8) an external interface that allows the IoT platform to be expandable and to be monitored from a mobile device. Different IoT platforms use different systems, as shown in Table 14.

Table 14

Articles in which the authors utilized IoT Platform

| Article | Year | IoT platform |

| Rouillard [73] | 2012 | Database for pricing the products using Prixing |

| Hou et al. [35] | 2013 | Cloud server to process data and prepare a shopping list |

| Sandholm et al. [75] | 2014 | X |

| Osisanwo et al. [65] | 2015 | X |

| Floarea et al. [23] | 2016 | Google Cloud |

| Hachani et al. [31] | 2016 | Cloud service |

| Kwon et al. [47] | 2016 | Apache Web Server-MSQL |

| Goeddel et al. [26] | 2017 | Cloud |

| Qiao et al. [70] | 2017 | Cloud-based Platform |

| Shama et al. [77] | 2017 | X |

| Wu et al. [89] | 2017 | Google Firebase |

| Anand et al. [6] | 2018 | Google Firebase |

| Hossain et al. [34] | 2018 | ThingSpeak |

| Nasir et al. [61] | 2018 | ThingSpeak |

| Rezwan et al. [71] | 2018 | Web Application GUI |

| Ahmed and Rajesh [4] | 2019 | Google Firebase |

| Ferrero et al. [22] | 2019 | Google Firebase |

| Khan et al. [41] | 2019 | Google Firebase |

| Ringe et al. [72] | 2019 | X |

| Dong et al. [18] | 2020 | Ubidots dashboard and database |

| Kore et al. [45] | 2020 | API |

| Mallikarjun et al. [52] | 2020 | Google Firebase |

| Nagarajua et al. [59] | 2020 | API |

| Velasco et al. [86] | 2020 | Cloud Server |

| Chakilam et al. [13] | 2021 | Google AI and Google Cloud |

| Che Soh et al. [14] | 2021 | Ubidots dashboard and database |

| Jain et al. [36] | 2021 | Google Firebase |

| Nadar et al. [58] | 2021 | X |

| Sane et al. [76] | 2021 | X |

3.14.Tablet/Touchscreen/PC

Smart refrigerators can be connected to household devices and the internet through external tablets or personal computers; some use built-in touchscreens. With a pre-installed application or web application, this tablet could communicate with all devices connected to the network. It also can receive, process, store, update and send information to a central database or a household mobile device. PC acts like tablets with more capabilities; they usually have extra capacity, provide a convenient programming environment, and serve as a home server. While touchscreens vary, some are like tablets and others just for a few functions. Here is a list of authors using different types of these devices in their systems, as shown in Table 15.

Table 15

Articles in which the authors utilized Tablets/PC in various systems

| Article | Year | Tablet/Touchscreen/PC |

| Hong et al. [33] | 2007 | PC |

| Luo et al. [51] | 2009 | TOUCHSCREEN |

| Nayak et al. [62] | 2011 | PC |

| Lloret et al. [49] | 2012 | PC |

| Bostanci et al. [11] | 2013 | PC application |

| Kaldeli et al. [38] | 2013 | PC |

| Hou et al. [35] | 2013 | Screen for display only |

| Son et al. [82] | 2014 | PC |

| Prapulla et al. [69] | 2015 | PC |

| Hachani et al. [31] | 2016 | Touchscreen with Voice message alerts |

| Esmaeili [5] | 2017 | X |

| Shama et al. [77] | 2017 | X |

| Wu et al. [89] | 2017 | TOUCHSCREEN |

| Fujiwara et al. [24] | 2018 | TOUCHSCREEN |

| Pachón et al. [66] | 2018 | User Interface |

| Zhongmin et al. [93] | 2018 | TOUCHSCREEN |

| Shariff et al. [78] | 2019 | PC |

| Avinash et al. [7] | 2020 | X |

| Chakilam et al. [13] | 2021 | Dashboard Cayenne |

| Datey [17] | 2021 | X |

| Gull et al. [27] | 2021 | PC |

| Jaipriya et al. [37] | 2021 | X |

| Krishnamoorthy et al. [46] | 2021 | X |

| Sane et al. [76] | 2021 | X |

3.15.Mobile application

Specifically designed software allows mobile devices to interact with the storage compartment in many ways, such as retrieving information, monitoring, controlling, and approving shopping lists. Several types of mobile applications are used in different papers, as shown in Table 16.

Table 16

Articles in which the authors used Mobile Application

| Article | Year | Mobile application |

| Lloret et al. [49] | 2012 | X |

| Bostanci et al. [11] | 2013 | X |

| Hou et al. [35] | 2013 | As a User Interface for the manual entry of items |

| Prapulla et al. [69] | 2015 | |

| Panchal et al. [67] | 2015 | Android application |

| Calegari et al. [12] | 2016 | X |

| Hachani et al. [31] | 2016 | X |

| Kwon et al. [47] | 2016 | X |

| Edward et al. [19] | 2017 | X |

| Qiao et al. [70] | 2017 | Intelligent terminal |

| Shama et al [77] | 2017 | X |

| Wu et al. [89] | 2017 | X |

| Fujiwara et al. [24] | 2018 | X |

| Hossain et al. [34] | 2018 | C |

| Nasir et al. [61] | 2018 | PushBullet |

| Rezwan et al. [71] | 2018 | X |

| Ahmed and Rajesh [4] | 2019 | As User Interface |

| Barfeh et al [8] | 2019 | Android |

| Ferrero et al. [22] | 2019 | For Voice interaction using Google Assistant SDK |

| Narayan et al. [60] | 2019 | X |

| Ringe et al. [72] | 2019 | Android |

| Abd Elminam et al. [1] | 2020 | X |

| Avinash et al. [7] | 2020 | X |

| Das et al. [16] | 2020 | X |

| Kore et al. [45] | 2020 | X |

| Mallikarjun et al. [52] | 2020 | X |

| Saha et al. [74] | 2020 | X |

| Velasco et al. [86] | 2020 | Android application |

| Datey [17] | 2021 | X |

| Gupta et al. [28] | 2021 | X |

| Jain et al. [36] | 2021 | Used for monitoring and shopping |

| Krishnamoorthy et al. [46] | 2021 | X |

| Nadar et al. [58] | 2021 | X |

| Sane et al. [76] | 2021 | X |

| Sharma et al. [80] | 2021 | X |

| Nejakar et al. [63] | 2022 | X |

3.16.Offline-database

In the reviewed papers, databases store information captured or received from the connected devices within the local network so the household can manage it. Different types of databases were used in the reviewed papers, as shown in Table 17.

Table 17

Articles in which the authors used systems with an offline-database

| Article | Year | Offline-database |

| Luo et al. [51] | 2009 | X |

| Lloret et al. [49] | 2012 | X |

| Panchal et al. [67] | 2015 | X |

| Goeddel et al. [26] | 2017 | X |

| Shweta [81] | 2017 | X |

| Nasir et al. [61] | 2018 | PLX-DAQ and MS Excel |

| Pachón et al. [66] | 2018 | X |

| Barfeh et al. [8] | 2019 | X |

| Sharma et al. [79] | 2019 | X |

| Das et al. [16] | 2020 | X |

| Kore et al. [45] | 2020 | A database uses the root (.CVS) |

| Datey [17] | 2021 | X |

| Krishnamoorthy et al. [46] | 2021 | X |

| Sharma et al. [80] | 2021 | X |

3.17.Webcam/camera module

Webcam means the reviewed paper used a camera to capture low-resolution images. A camera module means that the reviewed paper used a camera connected with a programmed device for image recognition and processing and/or higher resolution images. Some Authors used different types of cameras, as shown in Table 18.

Table 18

Types of cameras used in the literature

| Article | Year | Webcam/camera module |

| Bostanci et al. [11] | 2013 | Camera module |

| Kwon et al. [47] | 2016 | Camera module |

| Goeddel et al. [26] | 2017 | Camera module with Python coding |

| Shweta [81] | 2017 | Camera module |

| Wu et al. [89] | 2017 | X |

| Anand et al. [6] | 2018 | Adafruit |

| Pachón et al. [66] | 2018 | Camera module |

| Khan et al. [41] | 2019 | Camera module |

| Ringe et al. [72] | 2019 | Webcam |

| Sharma et al. [79] | 2019 | Camera module |

| Avinash et al. [7] | 2020 | Camera module |

| Dong et al. [18] | 2020 | Camera module |

| Kore et al. [45] | 2020 | Camera module |

| Mallikarjun et al. [52] | 2020 | Camera module-INTEXIT-305EC |

| Mohammad et al. [56] | 2020 | Camera module-CMOS |

| Nagarajua et al. [59] | 2020 | Camera module |

| Saha et al. [74] | 2020 | Camera module |

| Velasco et al. [86] | 2020 | Webcam |

| Chakilam et al. [13] | 2021 | Camera module |

| Che Soh et al. [14] | 2021 | Camera module |

| Datey [17] | 2021 | Camera module |

| Jain et al. [36] | 2021 | Camera module |

| Lee et al. [48] | 2021 | Camera module |

| Sane et al. [76] | 2021 | Camera module |

| Sharma et al. [80] | 2021 | Camera module |

| Nejakar et al. [63] | 2022 | Webcam |

3.18.Recognition module

The recognition module in this paper refers to machine learning or deep learning to recognize images, voices, and captured data. Algorithms and models enable the system to recognize and make decisions on the stored items’ status [11,55]. Also, they can use facial recognition to learn the consumption habits of each household member and form patterns accordingly, patterns of food use [11]. several methods of recognition modules are applied, as shown in Table 19.

Table 19

The recognition modules used in the literature

| Article | Year | Recognition module |

| Bostanci et al. [11] | 2013 | Fuzzy logic algorithm |

| Sandholm et al. [75] | 2014 | Google Image search engine |

| Kwon et al. [47] | 2016 | Fisher’s Linear Discriminant Analysis algorithm |

| Goeddel et al. [26] | 2017 | X |

| Shweta [81] | 2017 | Aging algorithm-Machine Learning |

| Anand et al. [6] | 2018 | X |

| Fujiwara et al. [24] | 2018 | X |

| Hossain et al. [34] | 2018 | X |

| Pachón et al. [66] | 2018 | CNN-to train the data for image recognition |

| Gao et al. [25] | 2019 | Deep Learning SSD algorithm |

| Khan et al. [41] | 2019 | X |

| Sharma et al. [79] | 2019 | CNN and DNN |

| Avinash et al. [7] | 2020 | X |

| Dong et al. [18] | 2020 | CNN-to train the data for image recognition and Deep Learning Framework Caffe |

| Kore et al. [45] | 2020 | Machine Learning ImageNet Classifier algorithm |

| Mallikarjun et al. [52] | 2020 | Machine Learning K-means Classifier algorithm |

| Mohammad et al. [56] | 2020 | CNN, Transfer Learning Technique and Inception V3 pre-trained model |

| Nagarajua et al. [59] | 2020 | CNN-to train the data for image recognition |

| Saha et al. [74] | 2020 | Machine Learning YOLO V3, Tiny YOLO and ImageAI library for training data |

| Chakilam et al. [13] | 2021 | CNN YOLO |

| Che Soh et al. [14] | 2021 | Faster R-CNN and SSD Mobilenet for object detection |

| Datey [17] | 2021 | X |

| Gull et al. [27] | 2021 | Machine learning to make a decision based on data from sensors |

| Jain et al. [36] | 2021 | CNN-Inception-V3 |

| Lee et al. [48] | 2021 | CNN and Object segmentation and argumentation Deep learning |

| Sane et al. [76] | 2021 | X |

| Sharma et al. [80] | 2021 | Transfer Flow Object classifier Deep Learning for image recognition and SMO Self Organizing Map for user behavior (NN) |

3.19.Approach and contribution of reviewed papers

The approach each reviewed paper used on the introduced systems towards a smart refrigerator is shown in Table 20, along with the papers’ contribution regarding storage compartments. Table 21 shows the limitations of and observations from each reviewed paper.

Table 20

Approach and contribution of reviewed articles

| Article | Year | Approach | Scientific/practical contributions |

| Loh et al. [50] | 2004 | IoT | Proposed a system uses IR Sensors for empty space sensing. |

| Hong et al. [33] | 2007 | IoT | Proposed a mathematical model for optimal replenishment policies using an RFID system. |

| Luo et al. [51] | 2009 | IoT | A novel smart refrigerator database to keep track of the nutrition of stored items based on a barcode reader using Microsoft SQL. |

| Konidala et al. [44] | 2011 | IoT | Security framework for RFID-based applications based on cryptographic methods and primitives and proposed system that keeps track of newly added items. |

| Nayak et al. [62] | 2011 | IoT | Proposed an IR sensing system that monitors a stored item’s stock level and generates an auto order to the nearest store. |

| Lloret et al. [49] | 2012 | IoT | Proposed a system that enables the refrigerator to inform the household via a Twitter account about the stored items’ levels. |

| Rouillard [73] | 2012 | IoT | Proposed a system to alert the household about stored items’ levels using a smartphone for barcode scanning, voice recognition, instant messaging, and an RFID scanner. |

| Bostanci et al. [11] | 2013 | AIoT | Uses fuzzy logic and neural network Hopfield NN single layer, One for food and one for facial recognition. |

| Hou et al. [35] | 2013 | IoT | Proposed a food management system using barcodes, RFID scanners, and manual entry of non-tagged items. |

| Kaldeli et al. [38] | 2013 | IoT | Proposed an RFID system to identify and monitor the stored items and a GSM module for communication. |

| Sandholm et al. [75] | 2014 | AIoT | Introduced a novel system that used a Google Image search engine for stored items recognition. |

| Son et al. [82] | 2014 | IoT | Proposed a system for diet management for wellness service refrigerators that allows the user to track stored and consumed RFID-tagged items. |

| Gürüler [30] | 2015 | IoT | Proposed a GSM module to enable a user to communicate with a refrigerator via SMS to learn the system status. |

| Kale et al. [39] | 2015 | IoT | Used a Contextual Inquiry (CI) for a better understanding of the household behavior in storing food items to help in designing designated trays for specific food items for tracking purposes. |

| Osisanwo et al. [65] | 2015 | IoT | Discussed the benefits and security challenges of smart refrigerators. |

| Prapulla et al. [69] | 2015 | IoT | Introduced a system that tracks stored items and communicates with the user via a GSM module and suggested access to be given to stores. |

| Panchal et al. [67] | 2015 | IoT | Introduced a system that tracks stored items and notifies the user via a GSM module for placing an order. |

| Calegari et al. [12] | 2016 | IoT | Proposed a tracking system for stored items using RFID and to be connected to other home appliances. |

| Floarea et al. [23] | 2016 | IoT | Introduced a system that tracks stored food items using RFID and provides a detailed description of the IoT platform. |

| Hachani et al. [31] | 2016 | IoT | Proposed a system that tracks the stored items using RFID and allows the refrigerator to alert the user via a voice messaging system embedded in an attached tablet. |

| Kwon et al. [47] | 2016 | AIoT | Introduced a system for stored items’ recognition using Fisher’s Linear Discriminant Analysis as a classifying algorithm. |

| Esmaeili [5] | 2017 | IoT | Proposed an MS Visual Studio application to send email alerts to users about the stored items’ status captured by RFID scanners. Provides some input components prices. |

| Edward et al. [19] | 2017 | IoT | Proposed a system with JavaScript code used for auto-replenishment using an IR sensor and barcode scanner. |

| Goeddel et al. [26] | 2017 | AIoT | Proposed a system with algorithms for shopping list creation using image recognition and weighing sensors. |

| Hafidh et al. [32] | 2017 | IoT | Proposed a system that tracks the stored items quantity and uses email to alert a user. |

| Qiao et al. [70] | 2017 | IoT | Proposed an automated system that tracks stored items and alerts a user about the system status using an RFID scanner and weighing sensors. |

Table 20

(Continued.)

| Article | Year | Approach | Scientific/practical contributions |

| Shama et al. [77] | 2017 | IoT | Proposed a system that allows users to remotely adjust the refrigerator temperature and know stored item levels by using RFID. |

| Shweta [81] | 2017 | AIoT | Proposed a system embedded with an Aging algorithm to identify the stored vegetable ages. A voice message is used to alert the user. |

| Wu et al. [89] | 2017 | IoT | Proposed an application that enables the user to receive a captured image each time the refrigerator is opened and manually update the stored item’s status. |

| Anand et al. [6] | 2018 | AIoT | Proposed a system that tracks the stored items’ status. Food quality could be known via its expiration date and predicted using gas sensors. The user could be updated via a mobile application. |

| Fujiwara et al. [24] | 2018 | AIoT | Proposed a system using speech recognition – for hands-free updates- where the user could identify items by names in a synchronous or asynchronous order. The system uses a weight sensor for each shelf. |

| Hossain et al. [34] | 2018 | AIoT | Proposed a conceptual framework for a neighborhood fridge network that allows tracking stored items in multiple connected refrigerators. |

| Nasir et al. [61] | 2018 | IoT | Proposed a system that measures the food quality using gas sensors and alerts a user via SMS, mobile application, or email. |

| Pachón et al. [66] | 2018 | AIoT | Proposed a system that detects produce using a region-based CNN tool. |

| Rezwan et al. [71] | 2018 | IoT | Proposed a prototype for a storage compartment that could measure the stored items’ quantity and alert the user at reorder point. Components prices for installation are included. |

| Zhongmin et al. [93] | 2018 | IoT | Proposed a system that tracks the food quantity and quality using weight and gas sensors. Describes selected components. A touchscreen is embedded to allow user interaction. |

| Abdel-Basset et al. [2] | 2019 | IoT | Proposed an IoT system for a Decision Support System on best food selection using an RFID scanner. |

| Ahmed and Rajesh [4] | 2019 | IoT | Proposed a system that tracks the food quantity using a weight sensor and alerts the user via a mobile application. |

| Barfeh et al. [8] | 2019 | IoT | Proposed a configuration of a controller to label each weight sensor with the item name for replenishment purposes. |

| Bayya [9] | 2019 | IoT | Proposed a system that tracks stored items’ quantity using a weight sensor and RFID scanner. It alerts the user via a GSM module every two hours. |

| Ferrero et al. [22] | 2019 | IoT | Proposed a system that tracks stored items and their expiration using RFID. Reviewed some scientific contributions regarding smart refrigerators. |

| Gao et al. [25] | 2019 | AIoT | Proposed a system for stored items’ recognition using YOLO and SSD framework. |

| Khan et al. [41] | 2019 | AIoT | Proposed a system using CNN to measure the number of eggs. Auto online ordering system. |

| Narayan et al. [60] | 2019 | IoT | Proposed a prototype framework of an inventory tracking system based on items weight like Amazon Dash Smart Shelf. |

| Ringe et al. [72] | 2019 | IoT | Introducing COAP network protocol for camera connection to the cloud to track stored items’ status. |

| Shariff et al. [78] | 2019 | IoT | Proposed a system that tracks the stored item status and uses a fire sensor detector MQ6 for safety. |

| Sharma et al. [79] | 2019 | AIoT | Proposed a system with CNN and DNN for image recognition and identification, as well as an IR camera for thermal images. |

Table 20

(Continued.)

| Article | Year | Approach | Scientific/practical contributions |

| Abd Elminam et al. [1] | 2020 | IoT | Proposed a system that uses an iPhone camera to scan items’ barcodes and alert the user of the expiration date of items. A temperature sensor turns on the fan to adjust the refrigerator’s temperature. |

| Avinash et al. [7] | 2020 | AIoT | Proposed a system with CNN for image recognition and identification, as well as making images clearer by applying CNN algorithms. |

| Das et al. [16] | 2020 | IoT | Proposed a system that enables the household to get notifications via SMS and mobile application for items status. |

| Dong et al. [18] | 2020 | AIoT | Proposed a system with a camera model using CNN, barcode and OCR (optical character recognition) for object recognition of stored items. |

| Kore et al. [45] | 2020 | AIoT | Proposed a system with a machine learning approach for image recognition and weighing sensors for stored items’ quantity. Twilio messaging system is used for SMS alerts. |

| Mallikarjun et al. [52] | 2020 | AIoT | Proposed a system with a K-means machine-learning classifier to classify stored vegetables along with ultrasonic, IR, and weight sensors for items quantity. |

| Mohammad et al. [56] | 2020 | AIoT | Proposed an Inception V3 pre-trained model for stored item’s detection along with an RFID scanner for item recognition. The components’ price list included. |

| Nagarajua et al. [59] | 2020 | AIoT | Proposed a system with CNN and NLP tools to recognize household voice commands and stored items recognition respectively. |

| Saha et al. [74] | 2020 | AIoT | Proposed a system with machine learning tools for items recognition. Compares YOLO and COCO detection models. |

| Velasco et al. [86] | 2020 | IoT | Proposed a system that tracks the stored items’ status and used the Temboo website to send data to Dropbox where the household can check on the refrigerator status. |

| Chakilam et al. [13] | 2021 | AIoT | Proposed a system that tracks the stored items’ status with the YOLO approach for item recognition. |

| Che Soh et al. [14] | 2021 | AIoT | Proposed a system that identifies and tracks the stored items’ status with a deep learning approach. Provided a comparison between SSD and R-CNN models. Uses Telegram to alert the household. |

| Datey [17] | 2021 | AIoT | Proposed a system that uses CNN and Regression prediction algorithms to suggest seasonal fruits and vegetables to the household. |

| Gull et al. [27] | 2021 | AIoT | Proposed an e-nose system for food item recognition using a machine learning approach (Decision Tree Advanced ID3 model) along with a weight sensor for quantity tracking. |

| Gupta et al. [28] | 2021 | IoT | Proposed a system that tracks stored items via weighing sensors and allows the user to control the storage climate using a mobile application. |

| Jain et al. [36] | 2021 | AIoT | Proposed a system that used weight sensors for items quantity, a gas sensor for Virus or Bacteria detection (UVC), and a camera with a CNN tool for item recognition and quantity. Compared different open-source datasets. |

| Jaipriya et al. [37] | 2021 | IoT | Designed a framework to ensure that items are trackable and placed correctly on the shelf or else alarm the user by led lamp. |

| Krishnamoorthy et al. [46] | 2021 | IoT | Proposed a system can identify the lowest cost of items with the expected delivery time via a loaded list. |

| Lee et al. [48] | 2021 | AIoT | Proposed an automatically labeled training data generator method. |

| Nadar et al. [58] | 2021 | IoT | Proposed an application with two options: auto-ordering or waiting for user instructions based on the weight of stored items. |

| Sane et al. [76] | 2021 | AIoT | Proposed a system with a machine learning classifier (OpenCV in Python) for image recognition along weighing sensor for stored items’ quantity. |

| Sharma et al. [80] | 2021 | AIoT | Proposed a system that tracks the user and generates an auto-order period based on household behavior. |

| Nejakar et al. [63] | 2022 | IoT | Proposed a system with a Blynk app to track stored items and enable viewing images from inside the fridge. |

Table 21

Limitations of and observations from reviewed articles

| Article | Limitations/observations |

| Loh et al. [50] | The proposed system is only conceptual. Transparent items such as water bottles cannot be detected using IR sensors. Item recognition is missing. Reorder point is not automated. Auto alert of system status. |

| Hong et al. [33] | The proposed system is only conceptual. Not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. Additional costs such as wastage are not included. Additional assumptions and constraints could be added to make the system more comprehensive and realistic. |

| Luo et al. [51] | The system is running locally, not fully automated, and applied only for healthcare purposes. Additional input components for system enhancement along with an internet connection to enable remote access. |

| Konidala et al. [44] | The proposed system is only conceptual. Not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. Practical implementation of the proposed systems. |

| Nayak et al. [62] | Transparent items such as water bottles cannot be detected using IR sensors. Additional input components for system enhancement. |

| Lloret et al. [49] | Additional sensors could be added to help in items’ identification. |

| Rouillard [73] | More utilization of the input information could result in providing system status about inventory level and auto reorder system. |

| Bostanci et al. [11] | The proposed system could be used in a shared dorm refrigerator as several users are there. For houses, the facial recognition feature might not be as useful. Instead, additional utilization of input information such as inventory level and auto reorder system would be great. |

| Hou et al. [35] | The proposed system is only conceptual. Also, automation of the tracking system would be great. |

| Kaldeli et al. [38] | The proposed system is only conceptual. The paper is about smart homes in general. Additional input components with actual implementation would be great. |

| Sandholm et al. [75] | Status of the inventory level is not mentioned. |

| Son et al. [82] | The proposed system is only conceptual. Not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Gürüler [30] | The input sensors were not specified. |

| Kale et al [39] | Automation and additional input sensor to recognize stored items could be more comprehensive. |

| Osisanwo et al. [65] | The proposed system is only conceptual. Not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Prapulla et al. [69] | Item recognition is missing. |

| Panchal et al. [67] | Item recognition is missing. |

| Calegari et al. [12] | The proposed system is only conceptual. Not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Floarea et al. [23] | Additional input sensors are required as not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Hachani et al. [31] | The proposed system is only conceptual. Additional input sensors are required as not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Kwon et al. [47] | Additional input sensors could help in tracking the inventory level status. |

| Esmaeili [5] | The proposed system is only conceptual. Additional input sensors are required as not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Edward et al. [19] | The proposed system is only conceptual. Additional input sensors are required as not all items are tagged with barcode tags. Not all barcode tags are the same. |

| Goeddel et al. [26] | The proposed system is only conceptual. Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

Table 21

(Continued)

| Article | Limitations/observations |

| Hafidh et al. [32] | Additional sensors could be added to help in items’ identification. |

| Qiao et al. [70] | The proposed system is only conceptual. Additional input sensors are required as not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Shama et al. [77] | Additional input sensors are required as not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Shweta [81] | Additional input sensors are required as not all items are vegetables and to enable tracking the inventory level. |

| Wu et al. [89] | The proposed system is only conceptual, and it would be great if it became automated. |

| Anand et al. [6] | The proposed system is only conceptual, and it would be great if an auto-order system is included. |

| Fujiwara et al. [24] | Requires specified space for each item. |

| Hossain et al. [34] | The proposed system is conceptual. An actual implementation could show the efficiency and effectiveness of the proposed system. |

| Nasir et al. [61] | Proposed system is only applicable for food items that generates gas, other sensors could be used to measure the quantity and be more comprehensive. |

| Pachón et al. [66] | Training the system with more items and adding additional components for quantity measurement could enhance the proposed system. |

| Rezwan et al. [71] | Requires specified space for each item. Additional sensors and automation of item recognition could enhance the system. |

| Zhongmin et al. [93] | The proposed system is only conceptual. Item recognition is missing. |

| Abdel-Basset et al. [2] | The proposed system is only conceptual. Additional input sensors are required as not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Ahmed and Rajesh [4] | The proposed system is only conceptual. Item recognition is missing. |

| Barfeh et al. [8] | Requires specified space for each item. Additional sensors and automation of item recognition could enhance the system. |

| Bayya [9] | Additional input for item recognition is required as not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Ferrero et al. [22] | The proposed system is only conceptual. Additional input sensors are required as not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Gao et al. [25] | Training the system with more items and adding additional components for quantity measurement could enhance the proposed system. |

| Khan et al. [41] | Training the system with more items and adding additional components for quantity measurement could enhance the proposed system. |

| Narayan et al. [60] | Requires specified space for each item. Additional sensors and automation of item recognition could enhance the system. |

| Ringe et al. [72] | The proposed system is only conceptual, and the item recognition method is not mentioned. |

| Shariff et al. [78] | Additional input sensors are required as not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Sharma et al. [79] | Additional input sensors could help in tracking the inventory level status. |

| Abd Elminam et al. [1] | Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

| Avinash et al. [7] | The proposed system is only conceptual. Additional input sensors could help in tracking the inventory level status. |

Table 21

(Continued)

| Article | Limitations/observations |

| Das et al. [16] | Additional input for item recognition is required and another communication medium could make it more comprehensive. |

| Dong et al. [18] | Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

| Kore et al. [45] | The machine learning approach was not specified. Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

| Mallikarjun et al. [52] | Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

| Mohammad et al. [56] | The proposed system is conceptual. Additional input sensors are required to help in tracking the inventory level status could make it more comprehensive as not all items are tagged with RFID tags. Not all RFID tags are compatible with all RFID readers. |

| Nagarajua et al. [59] | The proposed system is only conceptual. Additional input sensors could help in tracking the inventory level status. |

| Saha et al. [74] | Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

| Velasco et al. [86] | The machine learning approach was not specified. Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

| Chakilam et al. [13] | Training the system with more items could enhance the proposed system. |

| Che Soh et al. [14] | The proposed system is conceptual. Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

| Datey [17] | Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

| Gull et al. [27] | Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

| Gupta et al. [28] | The proposed system is conceptual. Automation and additional input sensor to help in items recognition could make it more comprehensive. |

| Jain et al. [36] | Training the system with more items could enhance the proposed system. |

| Jaipriya et al. [37] | Automation and additional input sensor to help in items recognition and tracking the inventory level status could make it more comprehensive. |

| Krishnamoorthy et al. [46] | Automation and additional input sensor to help in items recognition and tracking the inventory level status could make it more comprehensive. |

| Lee et al. [48] | The proposed system is conceptual. Automation and additional input sensor to help in tracking the inventory level status could make it more comprehensive. |

| Nadar et al. [58] | The proposed system is conceptual. Automation and additional input sensor to help in items recognition and tracking the inventory level status could make it more comprehensive. |

| Sane et al. [76] | The proposed system is conceptual. Automation and additional input sensor to help in items recognition and tracking the inventory level status could make it more comprehensive. |

| Sharma et al. [80] | The proposed system is conceptual. Automation and additional input sensor to help in items recognition and tracking the inventory level status could make it more comprehensive. |

| Nejakar et al. [63] | Training the system to be fully automated could enhance the proposed system. |

3.20.Analysis summary of the utilized components

This subsection provides a table that summarizes each reviewed paper’s used components. It consists of a list of authors in chronological order, and when a tie occurs between years, the authors are listed alphabetically. A checkmark (X) will indicate that the system introduced by each author included that component. The checkmark will be entered differently according to the footnotes for the recognition module and implementation type columns. The footnotes are repeated before each page break in Table 22.

Table 22

Summarization of used approach and components by the reviewed articles

| Reviewed article | Year (yy) | Approach | Components | ||||||||||||||||||||

| IoT | AIoT | IR sensors | Ultrasonic sensors | Climate sensor | Light sensor | Gas Sensor | Door Open-Close sensor | Weight sensor | GSM Module | RFID system | Barcode system | Connection medium | Controller1 | Internet Protocol2 | Offline-Database6 | IoT Platform3 | Touchscreen/PC | Mobile Application | Webcam/Camera module | Recognition module4 | Implementation (C, S, A)5 | ||

| Loh et al. [50] | 04 | X | X | X | X | X | C | ||||||||||||||||

| Hong et al. [33] | 07 | X | X | X | X | C | |||||||||||||||||

| Luo et al. [51] | 09 | X | X | X | X | X | S | ||||||||||||||||

| Konidala et al. [44] | 11 | X | X | X | X | C | |||||||||||||||||

| Nayak et al. [62] | 11 | X | X | X | X | X | X | X | X | S | |||||||||||||

| Lloret et al. [49] | 12 | X | X | X | X | X | X | X | X | X | X | X | X | A | |||||||||

| Rouillard [73] | 12 | X | X | X | A | ||||||||||||||||||

| Bostanci et al. [11] | 13 | X | X | X | X | X | X | S | |||||||||||||||

| Hou et al. [35] | 13 | X | X | X | X | X | X | X | C | ||||||||||||||

| Kaldeli et al. [38] | 13 | X | X | X | X | X | C | ||||||||||||||||

| Sandholm et al. [75] | 14 | X | X | X | X | X | X | X | A | ||||||||||||||

| Son et al. [82] | 14 | X | X | X | X | C | |||||||||||||||||

| Gürüler [30] | 15 | X | X | X | X | X | S | ||||||||||||||||

| Kale [39] | 15 | X | X | X | X | X | X | S | |||||||||||||||

| Osisanwo et al. [65] | 15 | X | X | X | X | X | X | X | C | ||||||||||||||

| Prapulla et al. [69] | 15 | X | X | X | X | X | X | S | |||||||||||||||

| Panchal et al. [67] | 15 | X | X | X | X | X | X | X | X | A | |||||||||||||

| Calegari et al. [12] | 16 | X | X | X | X | C | |||||||||||||||||

| Floarea et al. [23] | 16 | X | X | X | X | S | |||||||||||||||||

| Hachani et al. [31] | 16 | X | X | X | X | X | C | ||||||||||||||||

| Kwon et al. [47] | 16 | X | X | X | X | X | X | X | X | X | S | ||||||||||||

| Esmaeili. [5] | 17 | X | X | X | X | X | X | C | |||||||||||||||

| Edward et al. [19] | 17 | X | X | X | X | X | X | C | |||||||||||||||

| Goeddel et al. [26] | 17 | X | X | X | X | X | X | C | |||||||||||||||

| Hafidh et al. [32] | 17 | X | X | X | X | X | S | ||||||||||||||||

| Qiao et al. [70] | 17 | X | X | X | X | X | X | X | C | ||||||||||||||

| Shama et al. [77] | 17 | X | X | X | X | X | X | X | X | X | S | ||||||||||||