The Transition to a Circular Built Environment in Australia: An Analysis of the Jurisdictional Policy Framework

Abstract

The construction industry significantly impacts the built environment throughout its lifecycle from design, construction, operation to end-of-life considerations and decisions. In Australia, the industry generates almost 3 tonnes of waste per-capita, and this is expected to increase in the near future based on past trends. This paper focuses on understanding and analysing the various jurisdictional policy frameworks across Australia to support circular transitions in the built environment. Policy and regulatory leadership can enable and support grounding circular economy practices at national and state levels. The analysis found that circular economy frameworks rely heavily on recovery and recycling of construction waste, while there is minimal focus on designing out waste. This highlights that waste elimination within the policy setting is viewed as an end-of-pipe solution of minimising waste to landfill rather than a design led strategy. The focus on recycling within circular economy policies can led to public misconceptions about circularity, which can be a major barrier if systemic transitions are to be achieved.

1Introduction

The built environment refers to the human-made surroundings where people gather to live, work and play and encompasses both the physical structures and the supporting infrastructure.1 The built environment includes a range of interrelated sectors including buildings and construction, infrastructure, utilities and transport. These interdependencies across sectors mean that the built environment faces ‘wicked problems’ such as the impacts of climate change and resource use, which need to be considered from a holistic, systems thinking perspective.

The building and construction industries play an important role within the built environment as they lay the foundation for the development, operation and maintenance of the built environment. The construction sector is a major driver within the Australian economy accounting for 7.7% of Gross Value Added,2 while employing 8.8% of the labour force. Construction thus plays an influential role within the socio-political landscape of Australia, with economic recovery plans over the past two economic downturns being hinged on increases in construction projects endorsed by both national and state governments.

The construction industry in Australia generates 87 tonnes of waste per $ million of value added to the economy.3 As a sector the construction industry spent the most on waste services ($2 billion), a 35% increase since the previous year. In 2018-19 Australia generated about 74.1 million tonnes (Mt) of waste, at 2.94 tonnes per capita.4 Construction and Demolition (C&D) waste of 27Mt accounted for the largest portion of 44% of the total. Over the past 13 years, total waste generation in Australia increased by 18%, while C&D waste grew by 61%. Although per capita waste generation declined by 3.3% over this period, C&D waste increased by 32% on a per capita basis. Most of this increase in C&D waste has occurred within the last five years, caused by unprecedented levels of development, across the major cities.

Thus, it is evident that the construction sector needs to be a major area of focus for a transition to a circular built environment in Australia. Circular economy (CE) makes a fundamental change in “constructing, equipping, using and maintaining, altering and renewing” the built environment.5 CE in the built environment hasn’t had a consistent definition yet, but it can be understood as designing construction projects “that can be adapted, reconstructed and deconstructed to extend their life and that allow components and materials to be salvaged for reuse and recycling”.6 CE can be integrated in different stages of a built environment project with the implementation of CE principles in potential reuse of materials as well as disassembly and reuse design. Further, adoption of CE practices requires high level commitment amongst project stakeholders for circular design to be included in project delivery.7 However, previous studies focusing on circularity in the built environment often focus on assessing end-of-pipe solutions of C&D waste management8 9 10 with less focus on the regulatory and policy aspects.

In terms of CE transition in the construction industry, it is understood that regulatory frameworks play an important role to guide the construction market and businesses.11 Appropriate policy interventions towards a CE transition requires a deeper understanding of the sectoral understanding of business operations in a CE context and are influenced by existing socio-economic factors, together with the political perspective and prior policy choices.12 To unlock CE transition in this sector, this paper aims to understand how the policy landscape enables a circular transition of the built environment, through an in-depth analysis of jurisdictional policy frameworks in Australia. As part of the analysis, waste-related levies, waste strategies and circular economy policies across the states and territories of Australia were systematically reviewed and analysed. The policy frameworks were analysed from a built environment perspective with focus on factors affecting C&D waste and the broader construction sector.

The paper is structured in six sections as follows: a review of CE and built environment is presented in Section 2. Section 3 is research methodology and Section 4 is policy analysis including regulations and policies related to CE across different Australian states and territories. The next is Section 5 with the focus on discussion and the following is conclusions provided in the last section –Section 6.

2Circular economy and built environment

CE as a concept looks to move away from the conventional linear economic model of extraction, through production and consumption to final disposal, and has a range of meanings defined by various scholars and practitioners.13 14 CE is derived from diverse theories such as cradle to cradle,15 industrial ecology16 and industrial economics.17 The most cited CE definition is the concept from Ellen MacArthur Foundation,18 which defines CE as “an industrial system that is restorative and regenerative by intention and design. It replaces the ‘end-of-life’ concept with restoration, shifts towards the use of renewable energy, eliminates the use of toxic chemicals, which impair reuse, and aims for the elimination of waste through the superior design of materials, products, systems and within this, business models.”

Another highly cited CE definition is from Kirchherr et al.;19 “a circular economy describes an economic system that is based on business models which replace the ‘end-of-life’ concept with reducing, alternatively reusing, recycling and recovering materials in production/distribution and consumption processes, thus operating at the micro level, meso level, and macro level, with the aim to accomplish sustainable development, which implies creating environmental quality, economic prosperity and social equity, to the benefit of current and future generations”. Based on these definitions, CE requires efficient management to the end-of-life phase of a product.20

Responding to efficient management or “how-to” move towards CE, R strategies have been defined and developed across different studies. R strategies firstly includes “reduce, reuse and recycle”,2122 and then integrates “recover” as the fourth R strategy.23 R strategies have been extended to include more Rs, the most extensive being the 10Rs,24 which includes the strategies of “recover, recycle, repurpose, remanufacture, refurbish, repair, reuse, reduce, rethink and refuse”. Another important aspect that needs to be added to this framework of R’s is the concept of regeneration, the ability of the earth to revive itself especially for current and future generations of humans. These R frameworks show various strategies to undertake circularity at various stages of the economic cycle from the least preferred to the most preferred.

Construction is a unique sector with a complex process and the outcome is a one-off project, which has many phases served by different stakeholders. The integration of fundamental CE principles in the built environment needs to be considered, while a limited focus on resource efficiency and the use of recycled or reused materials in construction are not adequate to transition to CE. Pomponi & Moncaster25 developed a framework to study CE for the built environment. They used a three-tiered model of “macro (cities and neighbourhood), meso (buildings) and micro (assemblies and components)” to build a framework with six dimensions for CE to be addressed, including government, economic, environmental, behavioural, societal and technological. The success of circular construction is heavily influenced by stakeholder cooperation, and the top-level commitment of project stakeholders (Kanters, 2020). It has also been noted that low productivity in construction, under-utilisation of buildings, high energy consumption due to poor designs and inappropriate user behaviour and the presence of hazardous materials are all barriers to the adoption of CE practices in the built environment.26

The significance of enabling policies on the transition to a CE has been identified, as technology maturity within the sector is understood to have already been achieved.27 These policy factors can include a variety of government, management and economic policies, which can have a major influence on the implementation of circular strategies.28 Thus, it is evident that policy and regulatory leadership from governments can have a strong influence on the transition to a circular built environment. As a result, recent research has focussed on understanding how government policies enable the transition to circularity. Such studies typically focus on how national and regional policies impact the transition in a specific region29 or economic sector.30 However, the analysis of CE related policies affecting the transition of the Australian built environment is limited, with a majority of the research focussing on technical solutions within the construction and infrastructure sectors. This paper therefore, analyses policy influences within the Australian built environment sector to understand how such policies enable a holistic transition to a CE and what improvements are required.

3Research methodology

The research methodology used was a qualitative, deductive approach with the focus on reviewing and analysing policies across different states and territories as well as policies related to landfill levies and industry bodies that can affect broader CE transition. A qualitative approach helped in identifying nuanced differences and similarities between the policy landscapes across Australia. A deductive approach was used to understand how the different policy documents addressed key CE related principles.

A comparative analysis of policies was conducted based on a multi-level governance perspective. Multi-level governance highlights the importance of coordination between local, state and national governments and other non-state actors for environmental sustainability policies to be successful.31 A comparative analysis based on a multi-level governance perspective helps to understand the synergies between actors at different governance levels and the vertical and horizontal extensions of policies.32 The comparative analysis also helped in analysing policy coherence across the different jurisdictions and to identify possible synergies across different economic, social and environmental policy areas.33

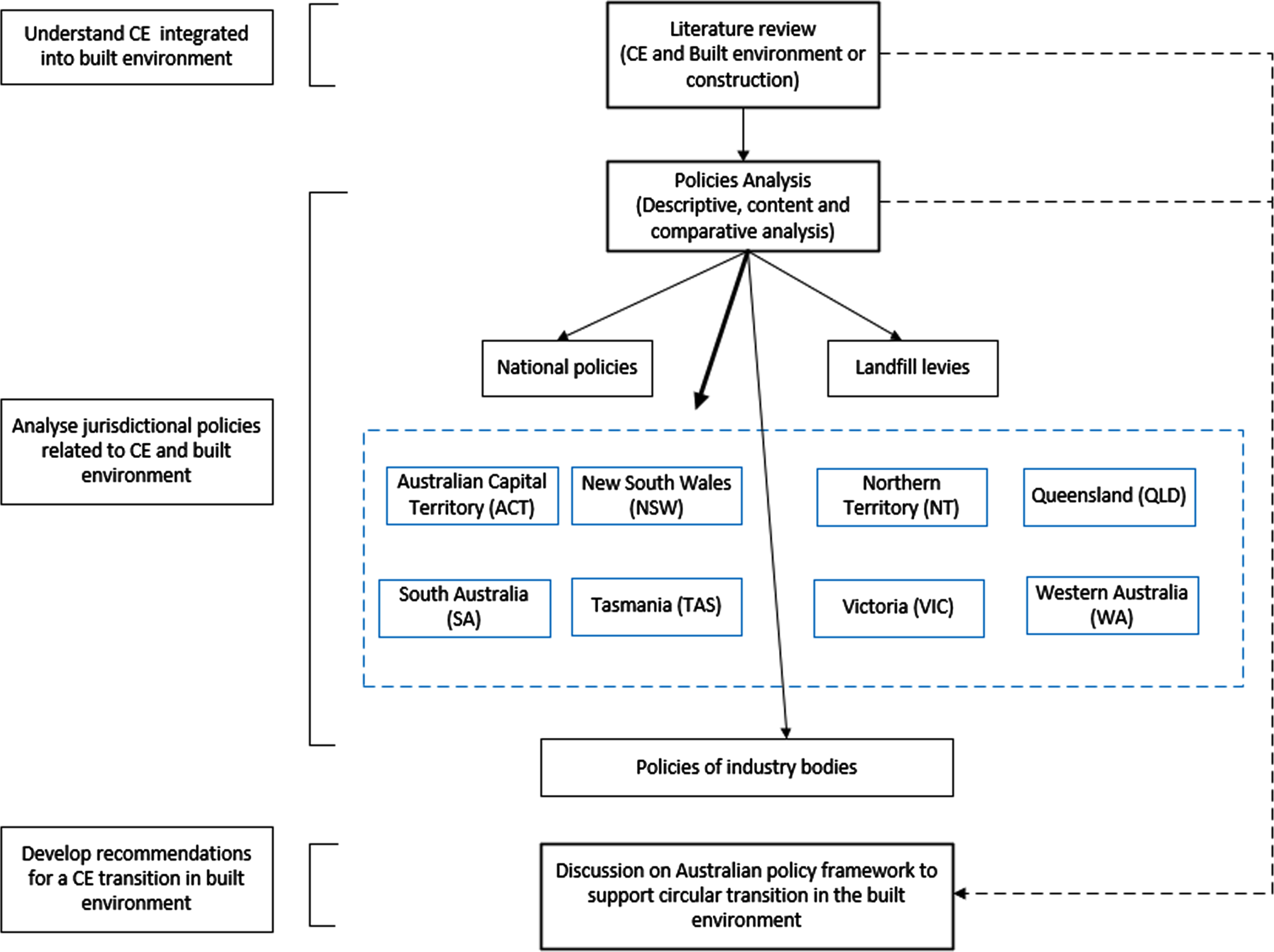

The policies included national levels CE policies, across jurisdictions, landfill levies and policies of industry bodies to possibly capture policies related to CE (see Fig. 1. Research methodology). The comparative analysis across these policies was conducted to understand how CE has developed in different states and implications of them that could be learnt across these states and territories.

Fig. 1

Research methodology.

4Policy analysis

This section aims to analyse the policies across different scale-levels from national policies, state and territory policies to policies of industry bodies. The analysis provides an in-depth understanding of what aspects of CE have been covered. Additionally it supports to understand CE transitions in different Australian states and territories. On the other hand, the analysis also demonstrates gaps of circular transition in the built environment, which need to be addressed by policies.

4.1National policy

The Australian waste regulation is the responsibility of the state and territory governments, with the federal government having legislative power over areas that affect the entire nation such as external affairs and international trade. With historical reliance of waste exports in Australia, national government policies on trade can have a major influence on waste management at state and territory levels. The overarching policy framework governing waste and resource recovery is the National Waste Policy.34 The policy outlines roles and responsibilities for collective action by stakeholders and sets targets to be attained at a national level.

The National Waste Policy seeks to provide a coordinated, national and common approach to tackling waste issues. This Policy has been prepared together by the Australian Government, State and Territory governments and the Australian Local Government Association. The Policy embodies a circular economy, and adopts CE principles for waste, recycling and resource recovery.

The main drivers for the Policy are waste reduction and resource recovery; financial and economic benefits; environmental pollution and greenhouse gas (GHG) emissions; public awareness; and the need for a national approach. The requirement for a national framework of programmes for sustainable production and consumption within the UN Sustainable Development Goals adopted by Australia is also a driver.

The Policy identifies five overarching principles underpinning waste management in a circular economy. These include avoiding waste, improving resource recovery, increasing the use of recycled material and building demand and markets for recycled products, better managing material flows to benefit human health, the environment and the economy, improving information to support innovation, guiding investment and enabling informed consumer decisions.

The specific targets and actions to implement the National Waste Policy is provided in the National Action Plan.35 Although no specific targets in relation to the construction sector is provided, the National Action Plan identifies that waste reduction of C&D waste and the promotion of CE in urban planning, infrastructure and development projects are required. A common point that was seen in the action plan was the increase in recycled content in the built environment. These policies include, determining the use of recycled content in road construction, development of national standards and specifications for the use of recycled content in road and rail projects and to improve demand for recycled materials in buildings and infrastructure.

The plan has a target of 10% reduction of per capita waste generation by 2030. However, it has also been noted that the definition of “per person” will be considered depending on potential unintended impacts on waste reduction initiatives from growth in construction and infrastructure developments.

4.2Australian Capital Territory (ACT)

The ACT’s CE framework is linked to its waste management strategy. The goal of the strategy is to drive innovation to achieve zero waste through a resource recovery programme and by supporting the shift to a carbon-neutral Canberra by 2050. The waste management strategy relies on less waste being generated, a full resource recovery programme, a clean environment and a carbon-neutral waste sector in the Australian Capital Territory.36 The waste policy has committed to pursuing a circular economy and action to date has been focused on waste management (reduce, reuse, recycle), and the focus on waste management has not unlocked the economic potential through an active business transition. The ACT has not yet developed a comprehensive economic strategy to transition to a circular economy.37

Although the highest proportion of waste generated in the ACT is C&D waste, no specific target for C&D waste has been set. However, multiple strategies focusing on C&D waste are specified. These strategies include encouraging on-site reuse of C&D waste, using recyclable materials in tendering of construction projects, rehabilitating soil from construction sites and temporary soil and C&D material exchange sites to reduce transport costs. The plan also targets urban planning requirements for multi-unit dwellings to manage household waste.

The ACT has specialised facilities for sorting C&D waste for use in building and road construction. This technology and high landfill prices have meant that the ACT is now diverting over 85% of the C&D waste stream. However, demand for recovered wood has not matched production in recent years leading to a significant increase in stockpiling and landfilling. Energy-from-waste technologies can create a sustainable market for this wood and support wider resource recovery from the construction and demolition sector36.

4.3New South Wales (NSW)

The NSW Circular Economy Policy Statement38 sets out the policy position for NSW’s transition to a CE. The Policy Statement takes a clear waste and environmental approach as the main driver. The economic impacts of resource optimisation, growth and job creation have been identified as additional benefits. This policy statement has been identified as the first step towards embedding circular economy considerations in government decision making, incorporating circular economy principles in government policies and strategies and planning the transition to a circular economy. Seven principles are seen to underpin the CE policy: Sustainable management of all resources, valuing resource productivity, designing out waste and pollution, maintaining the value of products and materials, innovating new solutions for resource efficiency, creating new circular economy jobs, fostering behaviour change through education and engagement.

The NSW Waste and Sustainable Materials Strategy 204139 sets clear directions and targets for waste management across the State. The targets are in line with national targets to reduce total waste generated by 10% per person by 2030, have an 80% average recovery rate from all waste streams by 2030 and significantly increase the use of recycled content by governments and industry. However, as the average recovery rate of C&D waste from 2016–2020 was 78%, it is evident that the focus will be on municipal solid waste (MSW) and commercial and industrial (C&I) waste streams. The strategy identifies that environmental impacts could be reduced by designing the built environment in a way that uses less materials, more durable and easily reparable. However, no specific objectives focusing on the life of buildings and infrastructure has been set out.

4.4Northern Territory (NT)

A specific CE policy has not yet been set up by the Northern Territory Government. The government’s waste management strategy has been updated to reflect new regulations focused on waste reduction and reuse, which represents a key underpinning for a transition to a CE.40 Although no specific targets and actions for C&D waste has been identified, one of the actions include the facilitation of opportunities to connect waste recovery and reuse markets with key waste producers, which include construction and demolition waste.

4.5Queensland (QLD)

Queensland’s Resource Recovery and Waste Management Strategy41 sets out clear strategic priorities for transitioning to CE for waste. The main drivers for the plan are waste management, economic growth, jobs and resource optimisation. The strategy has C&D targets for reduced landfill (85% by 2050) and increases recycling rates (>80% by 2050), although waste avoidance targets for C&D have not been specified. The reason stated for the lack of a waste avoidance target for C&D is because, C&D waste streams are linked to macroeconomic conditions. Although one of the strategic priorities of the strategy is building economic opoortunity, there are no economic Key Performance Indicators (KPIs) or targets linked to the strategy. Most of the proposed outcomes and actions under this strategic priority are business related rather than macroeconomic. However, advise from the Queensland Treasury has been sought on the KPIs which were adopted in the Waste Strategy.42

4.6South Australia (SA)

South Australia was the first state in Australia to quantify the benefits of CE, which it did in 2017. The state used macroeconomic modelling to show that interdependencies between 78 sectors can keep materials in the economy.43 South Australia’s Waste Strategy44 outlines actions that can contribute to the development of a circular economy and sets a 95% diversion rate for C&D waste by 2025. The strategy also has a target for per capita waste generation, 5% reduction on a 2020 baseline, which can also impact the per capita waste generation of C&D waste. The strategy identifies that action can result in a reduced need for new construction and demand on global resource consumption, and supporting adaptive reuse and retrofitting of existing building stock where possible has been identified as a priority action.

4.7Tasmania (TAS)

Tasmania has made the commitment to tackle their waste management and resource recovery issues and have released a Draft Waste Action Plan.45 The plan provides a framework for the State to address waste and resource recovery challenges. The plan identifies a number of key actions, including the establishment of a state-wide waste levy and the move to a circular economy.

Although the levels of recovery of C&D waste are significantly lower than the overall average recovery rates for Tasmania, no specific C&D recovery targets have been set. The focus is on investment into C&D sorting facilities and the use of price signals through levies to increase recovery rates. The overall targets of reducing waste generated by 5% per person by 2025 and 10% by 2030 and achieving a 40% average recovery rate from all waste streams by 2025 and 80% by 2030, encompasses the C&D stream.

4.8Victoria (VIC)

Recycling Victoria46 represents the Victorian Government’s action plan to reform the waste and recycling system, which was driven by bans on waste exports predominantly from China. A transition to a CE is underpinned by the plan and highlights that the State must become world-class recyclers, repairers, re-sellers and re-users. It is stated that a 5% improvement in materials efficiency could increase the size of the Victorian economy by $6.4 billion. The construction sector plays a major part within the Victorian waste landscape as around 43% of waste is generated from C&D activities.47

The main targets of the policy are a 15% reduction in total waste generation per capita between 2020 and 2030 and 80% diversion of waste from landfill by 2030, with an interim target of 72% by 2025. Although it has been identified that construction revolves around materials use and it has an important role to play in achieving these targets, no specific targets for C&D waste have been identified. As with most other states the focus is on using more recycled content in building and construction projects, with a special focus on the government’s role as a major purchaser.

The CE issues paper states that “if we carefully plan the way we design, construct and use our buildings and cities we can reduce the virgin materials used in their construction and the resources we use in them every day”. However, this outlook has not been explicitly transferred into the CE policy.

4.9Western Australia (WA)

Western Australia’s waste strategy identifies that the creation of a circular economy has the potential to harness the economic value of materials and drive investment in infrastructure and jobs.48 The waste hierarchy and the CE has been identified as guiding principles for the strategy. However, it could be noted that CE is looked at from more of a waste management focus rather than a material consumption focus. This is evident, as CE is defined as a system where the re-use and recycling of materials is a key component for “closing the loop”, with final disposal to landfill to be avoided. Waste products and materials in a circular economy are valued, and used for as long as possible to minimise pollution and resource depletion, and reduce greenhouse gas emissions.49

The strategy aims for a 20% reduction in waste generation per capita and an increase in material recovery to 75% by 2030. As with most other States C&D waste makes up around half of WA’s waste stream and represents around 45% of material recovered for recycling. The strategy also has specific C&D waste related targets such as reduction in C&D waste generation per capita by 30% by 2030 and increase material recovery in the C&D sector 80% by 2030. The C&D material recovery targets rely on increased use of C&D waste material in infrastructure and construction projects, especially those in the government sector through the Roads to Reuse program.50

4.10Landfill levies

Most jurisdictions across Australia have landfill levies implemented by state and territory governments. These levies act as a financial incentive towards increasing recovery rates and have been the main tool to increase recovery of C&D waste in many states and territories in Australia. The funds collected through these levies are most often used to fund recycling programs and infrastructure. Landfill levies are set according to different waste streams and the material that is being disposed of and can vary based on metropolitan and regional areas. NT and Tasmania are the only two States not having any landfill levies, although some regions in Tasmania have voluntary levies for some waste streams (see Table 1).

Table 1

Jurisdictional landfill levies relevant for C&D waste (based on 12 October 2021)

| Jurisdiction | Type of waste | Region | Levy ($/t) |

| ACT | C&I | – | 170.55 |

| Mixed C&I with >50% recyclable material | – | 232.7 | |

| NSW | General waste | Metropolitan | 147.10 |

| Virgin excavated natural material | Metropolitan | 132.40 | |

| General waste | Regional | 84.70 | |

| Virgin excavated natural material | Regional | 76.20 | |

| NT | – | – | – |

| Queensland | General waste including C&D | – | 85 |

| SA | Solid waste | Metropolitan | 146 |

| Solid waste | Non-metropolitan | 73 | |

| Tasmania | Voluntary levy | Varies for regions | 7.5 |

| Victoria | Industrial | Metro and regional | 105.90 |

| Industrial | Rural | 93.19 | |

| WA | Inert | – | 70 |

4.11Policies of industry bodies

Policy statements of industry and professional bodies relevant to the built environment sector in Australia were analysed to understand the policy and strategic position of these organisations towards CE.

Green Building Council of Australia51 supported an initial discussion on the role of CE in the Built Environment. It identifies the important role the built environment plays and how GBCA can drive CE within the sector. The Green Star rating tool was identified as the main enabler for driving CE practices in the building sector. The current ratings include several requirements that align with CE. These requirements are mainly focussed on waste management, resource use and carbon emissions targets.

Infrastructure Sustainability Council monitors CE outcomes for As Built certified infrastructure projects.52 The CE outcomes that are measured fall under sustainable sourcing, resource use efficiency and resource recovery outputs. Although no CE outcomes have been considered for the IS Design certification the report identifies the need to move urgently to next-generation circular design and that designing-in adaptability and end-of-life disassembly is vital for this purpose. Other international rating schemes are not explicitly mentioned here as they are not mandated but left to the discretion of individual companies/clients to determine their use in the project.

The policy positions of built environment industry bodies show that CE is viewed predominantly as a waste management strategy aligning with the principle of keeping materials in use. Little evidence in industry body policy positions were seen towards keeping products in use, which can be translated to the built environment sector as using existing building stocks more efficiently. An exception to this was the Australian Institute of Architects,53 that identified that incentives to encourage the alteration, retrofitting and rebuilding of current building stock is needed. It is also evident that economic value of infrastructure projects is viewed from an economic multiplier framework (how one dollar of investment increases GDP), which is a typical linear economic concept.54 55

5Discussion

The analysis of waste profiles and waste management strategies across Australia show that, although the built environment sector contributes to a large share of waste generated, not all jurisdictions have stipulated waste recovery targets for C&D waste (Table 2). Given high volume of C&D waste generated there is a necessity to have specific targets to encourage the building industry to reduce waste generation rather than focussing on waste treatment. Given the trend of higher increases in C&D waste in contrast to other waste categories, it is vital to reduce C&D waste generation rather than only focussing on increasing recycling rates. If waste generation does increase at the current pace, it may not be feasible to keep recycling this waste, especially as compositions and chemical make-up of the material changes over time.

Table 2

Jurisdictional summary of waste avoidance and diversion targets related to C&D waste

| Jurisdiction | C&D Waste diversion | Waste avoidance |

| National | 80% average resource recovery rate from all waste streams. | 10% per capita reduction by 2030 |

| ACT | The rate of resource recovery increases over 90% by 2025. | The growth in ACT waste generation is less than the rate of population growth |

| NSW | 80% average recovery rate from all waste streams by 2030 | reduce total waste generated by 10% per person by 2030 |

| NT | None | None |

| Queensland | reduced landfill (85% by 2050) and increased recycling rates (>80%) | None |

| SA | 95% diversion rate by 2025. | 5% reduction on a 2020 baseline |

| Tasmania | 40% average recovery rate from all waste streams by 2025 and 80% by 2030 | 5% per person by 2025 and 10% by 2030 |

| Victoria | 80% diversion of overall waste from landfill by 2030, and 72% by 2025. | 15% reduction in total waste generation per capita between 2020 and 2030 |

| WA | Reduction in C&D waste generation per capita by 30% by 2030 and increase material recovery of 80% by 2030. | 20% reduction in waste generation per capita |

A strategy focused primarily on recycling waste leads to major deficiencies from a CE perspective. Recovery and recycling are the least preferred R strategies and are more in line with a linear (recycling) economy rather than a CE. If the ever-increasing quantities of C&D wastes are to be recycled, it requires an endless production of building and infrastructure assets. Such a solution is against basic principles of CE, which aim to reduce the need for products in the first place and to eliminate waste through a circular design process. There are other technical challenges of trying to “recycle your way out” of a waste problem, as the increased construction will rely mainly on virgin materials with recycled content being used as a nice to have.

It can be identified that CE/waste strategies focus mainly on solid waste and that liquid waste is not a focus within them. Liquid waste in the construction industry can be an issue, if large amounts of ground water from drilling activities are discharged into the sewer system, which is not suited to handle such discharges. Wash water from equipment and tool washing during construction can include chemical residue, which is a reportable priority waste.56 As such, waste and CE policies could be improved by taking into consideration the wastewater from construction activities. The CE strategies also illustrate that the current focus on the built environment is more from a waste hierarchy point of view rather than a more systemic approach. The inert nature of the majority of building materials lends themselves to be reused repeatedly if high-quality recovery can be facilitated and stored or stockpiled to be used in the future. This shows that there is good potential for the built environment sector to be a major factor in the transition from a recycling economy to a CE. Also, if the right levers are used, the construction industry may easily move to CE transitions through different approaches in its supply chains.

The design stage should focus on the CE transition in the construction industry as it is a crucial stage of a building project with the ability to assist in the shift to more circularity. The design of a building is reliant on material use and other resources needed to operate buildings. Lifecycle thinking integrated to project design regarding materials, technologies, innovations and waste management are high impact elements of the lifecycle of a construction project. The implementation of various approaches such as design for disassembly, prefabrication, reused materials and/or 3D printing could be utilised. More modular construction should be promoted, and off-site construction should be encouraged. These approaches need designers to consider a circular thinking to implement them into design practices during a project lifecycle that align with CE principles in the built environment. However, with the current focus of policies on end-of-pipe solutions such actions are not incentivised.

A majority of the CE strategies tend to rely on the construction and infrastructure sectors to use waste from other sectors as an input material. Although no specific targets have been specified, work is being conducted to develop standards and metrics for the use of recycled content in construction both at national and state levels. Municipal waste such as plastic, rubber, glass and white goods are being popularised to be used in road and pavement construction. However, using such materials as road base may not be the best option based on CE principles and even waste hierarchy, as such uses promote materials to be downcycled. The technical cycle of these materials needs to be considered to understand whether the materials could be used in more efficient manner and how the composite construction material can be mined at the end of its life. Further to this, it has been found that use of wastes such as plastic in construction material exacerbate the negative ecological, health, and social impacts of plastic waste and increase demand for continued production of new (virgin) plastics by creating new markets for plastic wastes.57 Thus it is vital that policy makers consider longer term impacts and design strategies to eliminate waste rather than using infrastructure assets as “linear landfills”, which distract from finding real solutions.

The indicators that measure circularity focus on the preservation of materials through recycling and downcycling. Such targets are classified as basic level, scope 0 targets, when technological cycles and cause and effect chains are considered.58 Comparing these indicators to accepted definitions of CE, it is evident that the CE policies focus on closing-loops and not on slowing-loops,59 which can be achieved through design of long-life buildings and extension of a buildings life. Although the use of recycled material in buildings were considered in most states, there are no policy considerations such as government procurement practices to optimise recovery of building materials. The lack of such targets can have a negative impact on transitioning to a circular built-environment, as premature demolition and shortened lifespan of buildings have negative environmental impacts, even with the promotion of more sustainable new-builds.60 61 This is exacerbated further by the multitude of the political-economic factors that favour new-builds over maintenance and refurbishment of existing buildings.62

The analysis of industry standards and guidelines in Australia also illustrate that CE related aspects focus on reducing waste and using recycled content. This is in contrast to more advanced economies where criteria such as whether buildings are fit for the future, reuse of existing building components in new developments and higher use intensity of usable building areas are assessed as circularity metrics.63 Direct policy actions from governments that can drive product re-use from a top-down perspective and including mandatory re-use targets within policies could also drive a more holistic CE transition.64

A key target driving waste reduction is the national target to reduce waste generated by 10% per person by 2030. However, the action plan states that the definition of per person will be “informed by analysis of any potential unintended impacts on waste reduction initiatives from growth in construction and infrastructure developments”. This indicates that waste reduction targets seem to focus on MSW rather than broader built environment related waste. This further highlights that increased construction and infrastructure is viewed as an essential requirement within the economy, which is in contrast to CE principles of making use of existing products in a more efficient manner without having to build new infrastructure. In addition, economic benefits of CE within policies are estimated using conventional linear economic concepts such as GDP. As such these policies show that CE is seen as an add on to conventional linear economic growth models, which are contradictory to fundamental CE principles.

One of the typical CE strategies is the extended producer responsibility (EPR) that should also be supported by governments. As highlighted in the research of Sante65 focusing on business models on road projects, the EPR is important and can be integrated under the maintenance model. This model aims to lengthen a product lifecycle and to keep it in use as long as possible, which is one of the fundamental CE principles. In this model, a service contract should be provided to show producer responsibilities to customers. An example is Phillips –a well-known lighting producer, who developed the model of providing services instead of selling products. Phillips provides lights (lux), light fitting, material passports, repair services and remanufacture at the end of life.66 This case study can be a lesson that may be widely implemented, for the built environment that has a wide range of suppliers and contractors across a projects lifecycle. However, this strategy in the built environment has not yet been supported by the current national policy.

As in the construction industry, project practices are very important to shape or change thinking of project stakeholders especially clients, designers and contractors to better understand CE. Governments at all levels should develop CE project practices to show benefits as well as CE implementation at different stages of a project rather than only focusing on waste management and recycling as mentioned in the regulatory framework. The construction industry is at the initial stages of integrating and developing CE and there is still a lack of industry-wide practices to support and orient the construction industry to transparently move towards CE.67 Since the built environment industry has longer time frames of construction and operation, it is very important that CE guidelines are set in place to support this long-term thinking and application of CE. Business operations which cover operations and maintenance can also become part of this life cycle that is supportive of CE rather than inhibit CE. In addition, governments should create the environment for developing collaboration amongst the various project stakeholders as well as across different disciplines to discover opportunities of implementing CE principles between different industries such as plastics and infrastructure or printing and infrastructure to reduce the waste of plastics and printing cartridges by considering it as input materials for infrastructure projects. Cross sector opportunities need to be fully explored.

Finally, the language around CE also needs to be considered. The term C&D waste is used widely across the policy documents. If waste is not considered as a resource, it is always going to be considered to be of low value that promotes inherently, the idea of down cycling rather than upcycling. Therefore, the terms such as resource use, value-add and resource recovery are encouraged so that the intent of retaining value and upcycling is supported. The term de-construction rather than demolition could be used to shift mind-sets towards more circular thinking in the industry. The term deconstruction aligns with higher order R strategies like refurbish and repair, while demolition leads to unrecoverable materials which may even inhibit recovery and recycling.

6Conclusion

This paper aimed to understand the regulatory framework underpinning circularity in the built environment. To achieve this aim CE policies and strategies across state and federal jurisdictions and industry standards within the building sector were analysed. Analysing the regulatory framework provided insights into the foundation that circularity transition of the built environment relies on. A limitation of this approach is that the implementation of the policies, their effectiveness in real life and other initiatives stemming from the policies have not been assessed.

The analysis found that CE frameworks rely heavily on the recovery and recycling of C&D waste, while there is minimal focus on designing out waste in the built environment sector. It could be inferred that waste minimisation within the policy setting is viewed as an end-of-pipe solution rather than a design lead strategy. The focus on recovery and recycling within CE policies can also lead to public misconception that CE is a waste management (recycling) strategy. This lack of understanding can be a major barrier if systemic transitions are to be achieved.

A foundational regulatory framework based on higher order CE strategies is needed to drive the construction industry to become more circular. A regulatory platform, supported by an enabling governance structure can enhance collaboration between federal, state and territory governments to draft regulations and policies that are applicable to the construction industry. As construction materials are predominantly inert, this is an untapped opportunity for material to be reused and recycled repeatedly if appropriate design strategies are set in place. While waste can be a driver for use of materials in infrastructure projects such as road projects with the recycling of plastic and glass, this should not be the long-term strategy as CE calls for waste to be reduced and eventually, eliminated. Other potential areas in the construction industry of shifting to CE should consider all the options under the R strategies and a scaffold of this considered as part of life cycle design and operation so that end-of-life factors are considered at the initial stages of a project.

To move towards CE, various approaches need to be considered that support developing strategies at the macro level. Beyond waste management and recycling, the policy framework needs to be underpinned by much broader, holistic circular economy thinking. This is especially relevant to the built environment sector in Australia or similar economies, where there is a big focus on construction and infrastructure as a source of traditional economic growth.

Notes

1 State of the Environment 2011 Committee. (2011). Australia state of the environment 2011. Independent report to the Australian Government Minister for Sustainability, Environment, Water, Population and Communities. DSEWPaC, Canberra.

2 Australian Bureau of Statistics. (2020). Australian System of National Accounts 5204.0, Table 5. Gross Value Added (GVA) by Industry. ABS.

3 Australian Bureau of Statistics. (2020b). Waste Account Australia 4602055005_201819, Experimental Estimates, 2018-19. ABS.

4 Pickin, J., Wardle, C., O’Farrell, K., Nyunt, P. & Donovan, S. (2020). National Waste Report 2020. Blue Environment Pty Ltd.: Melbourne, Australia.

5 Mayor of London. (2020). Design for a circular economy, Primer- Good growth by design, London.

6 Cheshire, D. (2019). Building revolutions: Applying the circular economy to the built environment. Riba Publishing.

7 Van den Berg, M., Voordijk, H., & Adriaanse, A. (2019). Circularity challenges and solutions in design projects: an action research approach. In 35th ARCOM Conference. 2019 September

8 Foˇt, J. and Černý, R., 2020. Transition to circular economy in the construction industry: Environmental aspects of waste brick recycling scenarios. Waste Management, 118, pp.510-520.

9 Mahpour, A. (2018). Prioritizing barriers to adopt circular economy in construction and demolition waste management. Resources, conservation and recycling, 134, 216-227.

10 Ratnasabapathy, S., Alashwal, A., & Perera, S. (2021). Exploring the barriers for implementing waste trading practices in the construction industry in Australia. Built Environment Project and Asset Management, 11(4), pp. 559-576

11 Brandão, R., Hosseini, M.R., Macêdo, A.N., Melo, A.C. & Martek, I. (2021). Public administration strategies that stimulate reverse logistics within the construction industry: a conceptual typology, Engineering, Construction and Architectural Management, Vol. 29 No. 8, pp. 2924-2949

12 Milios, L. (2021). Overarching policy framework for product life extension in a circular economy— a bottom-up business perspective. Environmental Policy and Governance, 31(4), pp.330-346.

13 Lieder, M., & Rashid, A. (2016). Towards circular economy implementation: a comprehensive review in context of manufacturing industry. Journal of cleaner production, 115, 36-51.

14 Murray, A., Skene, K., & Haynes, K., (2017). The circular economy: an interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 140 (3),369–380.

15 McDonough, W., & Braungart, M. (2005). Cradle to cradle. McGraw-Hill Education.

16 Ayers, Robert as cited in Ausubel, Jesse H & Sladovich, Hedy E. (1989). Technology and Environment: An Overview Technology and Environment, National Academy of Engineering, National Academy Press, Washington, DC, pp 6-77.

17 Stahel, W. R. (1982). The product life factor. An Inquiry into the Nature of Sustainable Societies: The Role of the Private Sector, (Series: 1982 Mitchell Prize Papers), NARC

18 Ellen MacArthur Foundation. (2012). Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition. Available at https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an, Accessed 25 November 2021.

19 Kirchherr, J., Reike, D., & Hekkert, M. (2017). Conceptualizing the circular economy: An analysis of 114 definitions. Resources, conservation and recycling, 127, 221-232

20 Marconi, M., & Germani, M. (2017). An end of life-oriented framework to support the transition toward circular economy. In DS 87-5 Proceedings of the 21st International Conference on Engineering Design (ICED 17) Vol 5: Design for X, Design to X, Vancouver, Canada, 21-25.08. 2017 (pp. 199-208).

21 Ghisellini, P., Cialani, C. & Ulgiati, S. (2016). A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. Journal of Cleaner Production 114, 11e32

22 King, A. M., Burgess, S. C., Ijomah, W., & McMahon, C. A. (2006). Reducing waste: repair, recondition, remanufacture or recycle?. Sustainable development, 14(4), 257-267.

23 European Commission. (2008). Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives.

24 Potting, J., Hekkert, M. P., Worrell, E., & Hanemaaijer, A. (2017). Circular economy: measuring innovation in the product chain (No. 2544). PBL Publishers.

25 Pomponi, F., & Moncaster, A. (2017). Circular economy for the built environment: A research framework. Journal of cleaner production, 143, 710-718.

26 Ellen MacArthur Foundation. (2015). Growth within: A Circular Economy Vision for a Competitive Europe.

27 D’Adamo, I., Mazzanti, M., Morone, P. and Rosa, P., (2022). Assessing the relation between waste management policies and circular economy goals. Waste Management, 154, pp.27-35.

28 Lahane, S., & Kant, R. (2022). Investigating the sustainable development goals derived due to adoption of circular economy practices. Waste Management, 143, 1-14

29 Márquez, A. J. C., & Rutkowski, E. W. (2020). Waste management drivers towards a circular economy in the global south–The Colombian case. Waste Management, 110, 53-65.

30 Guzzo, D., Rodrigues, V. P., Pigosso, D. C., & Mascarenhas, J. (2022). Analysis of national policies for Circular Economy transitions: Modelling and simulating the Brazilian industrial agreement for electrical and electronic equipment. Waste Management, 138, 59-74.

31 Bulkeley, H. & Betsill, M. (2005). Rethinking sustainable cities: Multilevel governance and the’urban’politics of climate change. Environmental politics, 14(1), pp.42-63.

32 Liu, M. & Lo, K., (2021). A comparative review of urban climate governance in Chinese and Western contexts. Urban Governance, 1(2), 81-88.

33 Nilsson, M., Zamparutti, T., Petersen, J.E., Nykvist, B., Rudberg, P. & McGuinn, J. (2012). Understanding policy coherence: analytical framework and examples of sector–environment policy interactions in the EU. Environmental policy and governance, 22(6), pp.395-423.

34 Commonwealth of Australia. (2018). 2018 National Waste Policy: less waste more resources, Commonwealth of Australia 2018.

35 Commonwealth of Australia. (2019). National Waste Policy Action Plan 2019, Commonwealth of Australia 2019.

36 Environment and Sustainable Development Directorate. (2011). ACT Waste Management Strategy: Towards a sustainable Canberra, Environment and Sustainable Development Directorate, Australian Capital Territory, Canberra

37 Office of the Commissioner for Sustainability and the Environment. (2019). Unlocking the Potential of a Circular Economy in the ACT, Office of the Commissioner for Sustainability and the Environment, Canberra.

38 State of NSW and NSW Environment Protection Authority. (2019). NSW Circular Economy Policy Statement: Too Good to Waste, Environment Protection Authority, NSW.

39 Department of Planning, Industry and Environment. (2021). NSW Waste and Sustainable Materials Strategy 2041, Stage 1:2021–2027, State of New South Wales, June 2021

40 Northern Territory Environment Protection Authority. (2015). Waste Management Strategy for the Northern Territory 2015–2022

41 Queensland Government. (2019). Waste Management and Resource Recovery Strategy.

42 State of Queensland. (2018). Queensland Waste Strategy –Key Performance Indicators, Queensland Treasury Corporation, September 2018.

43 Iyer-Raniga, U., 2020. State of play for circular built environment in Oceania. A report compiling the regional state of play for circularity in the built environment in Oceania across Australia and New Zealand.

44 Green Industries SA. (2020). Supporting the Circular Economy: South Australia’s Waste Strategy 2020-2025, Green Industries SA, Adelaide, South Australia

45 Department of Primary Industries, Parks, Water and Environment. (2019). Draft Waste Action Plan: Consultation Draft, Tasmanian Government, June 2019.

46 The State of Victoria Department of Environment, Land, Water and Planning. (2020). Recycling Victoria A new economy, February 2020.

47 The State of Victoria Department of Environment, Land, Water and Planning. (2019). A circular economy for Victoria: Creating more value and less waste, Issue Paper, July 2019.

48 Waste Authority. (2018). Waste Avoidance and Resource Recovery Strategy 2030: Western Australia’s Waste Strategy. Waste Authority. Joondalup, Western Australia

49 Department of Water and Environmental Regulation. (2020). Closing the loop –waste reforms for a circular economy: Consultation paper, Government of Western Australia, Joondalup, WA, February 2020,

50 Waste Authority. (2018). Waste Avoidance and Resource Recovery Strategy 2030: Action Plan 2021-22. Waste Authority. Joondalup, Western Australia

51 Green Building Council of Australia. (2021). A circular economy discussion paper, March 2021.

52 Infrastructure Sustainability Council. (2021). Infrastructure Sustainability Council: 2021 Annual Impacts Report.

53 Australian Institute of Architects. (2021). Institute Policy and advocacy statements: Sustainability policy

54 Green Building Council of Australia. (2020). Building to bounce back: Together, we can build a sustainable future.

55 RPS Group. (2020). IS Rating Scheme Return on Investment: Cost benefit analysis of the Infrastructure Sustainability (IS) Rating Scheme, Prepared for Infrastructure Sustainability Council of Australia.

56 Karunasena, G., Gajanayake, A. & Udawatta, N., (2022). Wastewater management in the construction sector: a systemic analysis of current practice in Victoria, Australia. International Journal of Construction Management, pp.1-10.

57 Cirino, E., Curtis, S., Wallis, J., Thys, T., Brown, J., Rolsky, C. and Erdle, L.M., (2023). Assessing Benefits and Risks of Incorporating Plastic Waste in Construction Materials. Frontiers in Built Environment, 9, p.1206474.

58 Moraga, G., Huysveld, S., Mathieux, F., Blengini, G.A., Alaerts, L., Van Acker, K., De Meester, S. & Dewulf, J. (2019). Circular economy indicators: What do they measure?. Resources, Conservation and Recycling, 146, pp.452-461.

59 Bocken, N.M., De Pauw, I., Bakker, C. & Van Der Grinten, B. (2016). Product design and business model strategies for a circular economy. Journal of industrial and production engineering, 33(5), pp.308-320.

60 Marsh, R. (2017). Building lifespan: effect on the environmental impact of building components in a Danish perspective. Architectural Engineering and Design Management, 13(2), pp.80-100.

61 Shen, L.Y., Yuan, H. & Kong, X. (2013). Paradoxical phenomenon in urban renewal practices: promotion of sustainable construction versus buildings’ short lifespan. International Journal of Strategic Property Management, 17(4), pp.377-389.

62 Teo, P., Gajanayake, A., Jayasuriya, S., Izaddoost, A., Perera, T., Naderpajouh, N. & Wong, P.S. (2021). Application of a bottom-up approach to estimate economic impacts of building maintenance projects: cladding rectification program in Australia. Engineering, Construction and Architectural Management. 29(1), pp.333-353

63 DGNB –German Sustainable Building Council. (2020). DGNB System –New buildings criteria set, DGNB GmbH.

64 Milios, L. (2021). Overarching policy framework for product life extension in a circular economy— a bottom-up business perspective. Environmental Policy and Governance, 31(4), pp.330-346.

65 Sante, M.V. (2017). Circular construction –Most opportunity for demolishers and wholesalers, ING, https://think.ing.com/uploads/reports/ING_EBZ_Circular-construction_Opportunities-for-demolishers-and-wholesalers_juni-2017.pdf, Accessed 24 November 2021.

66 Jones, P., & Comfort, D. (2018). The construction industry and the circular economy. International Journal of Management Cases, 20(1), 4-15.

67 Hjaltadóttir, R. E., & Hild, P. (2021). Circular Economy in the building industry European policy and local practices. European Planning Studies, 1-26.